Get faster and more reliable engineering insights to inform product decisions by connecting fast, Physics AI–powered models to real-world systems and data.

Talk to an expert

Move from historical analysis to real-time understanding, getting instant feedback on how your assets are performing in the field.

Use predictive insights to anticipate maintenance needs, optimize performance, and prevent costly, unplanned downtime.

Receive early warnings of potential performance degradation or component failures, giving you time to act before a critical issue occurs.

Create a closed loop where live field data feeds back into your R&D process, providing invaluable insights for the next generation of products.

How it works

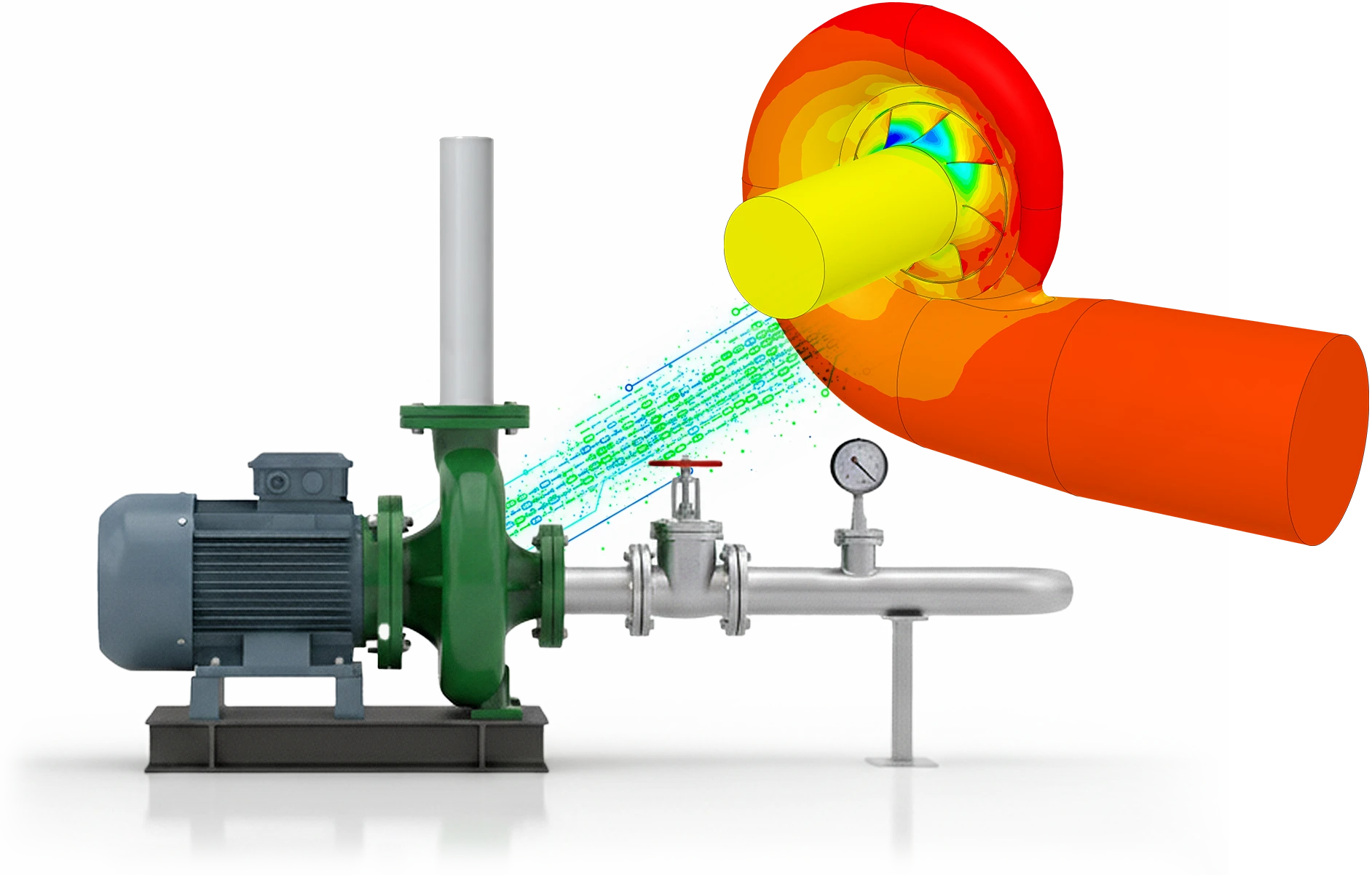

Deploy lightweight, AI-powered models trained on high-fidelity simulation data. These reduced order models run in real time, providing instant performance predictions without the computational cost of a full physics simulation, making them ideal for live applications.

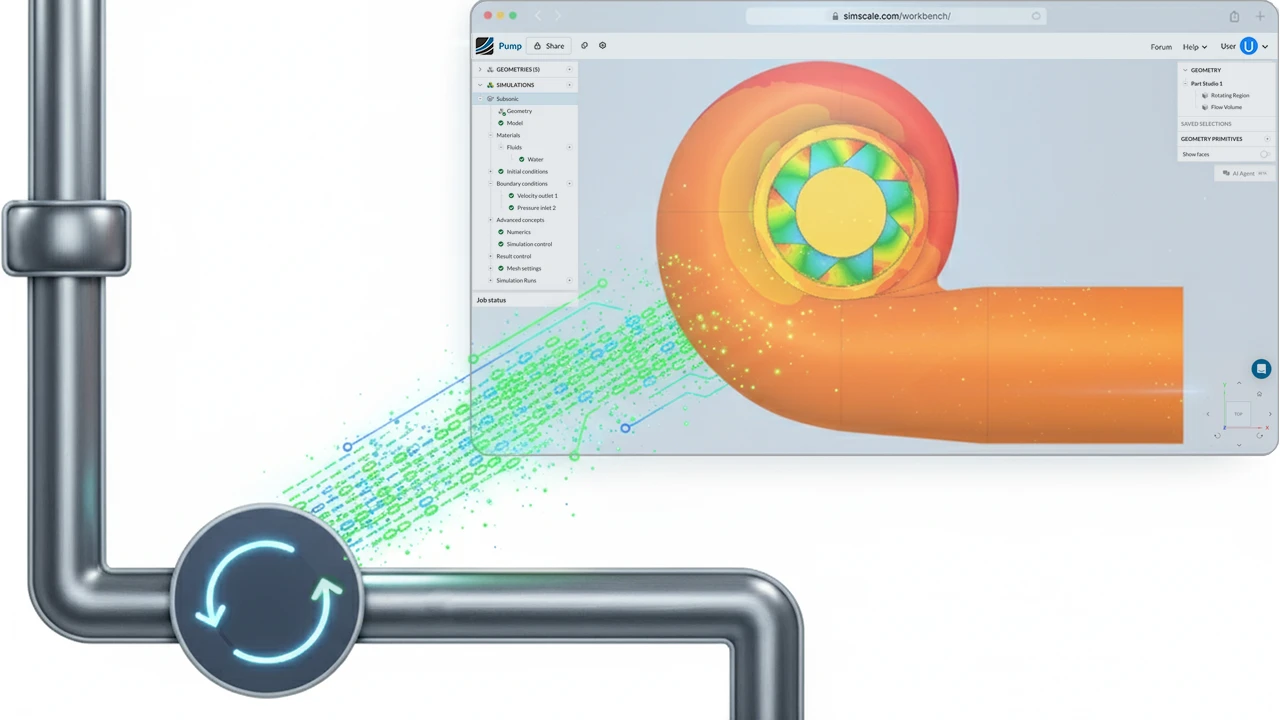

Connect live sensor data streams from your operational assets or system-level models directly to Physics AI surrogates via our open API. This creates a closed loop where real-world conditions continuously inform and update your digital twin for maximum accuracy.

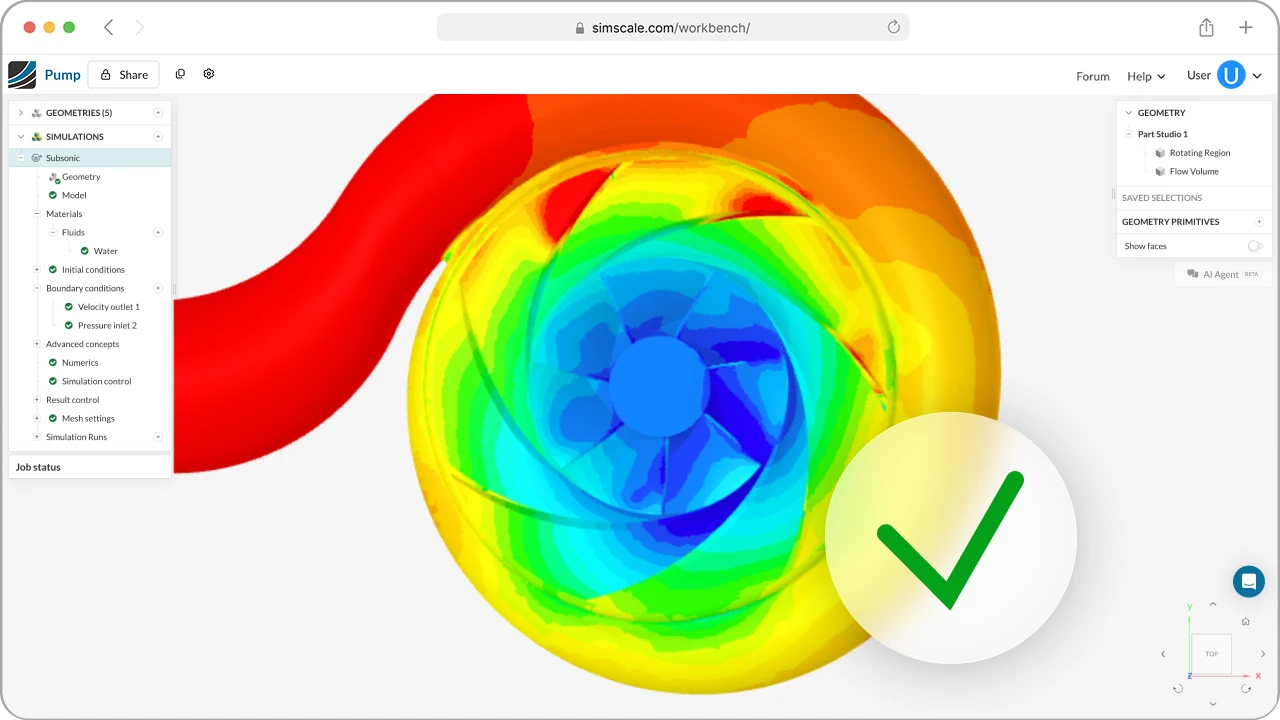

Move from reactive maintenance to predictive operations. By combining live data and hardware-in-the-loop (HiL) setups with AI models, you can forecast performance degradation and potential failures before they occur, preventing costly downtime and improving asset reliability.

“I have been using SimScale in my product development routine (weekly) and it has been a game changer in critical design decisions where industrial equipment is used in large scale industrial operations.”

Vinícius Gonçalves

Senior Engineer at Vale

Sign up for SimScale

and start simulating now