Physical prototyping is expensive and slow. Material waste, over-engineering, and late-stage design changes inflate R&D budgets, putting teams under pressure to cut costs without compromising on performance or safety. SimScale breaks this cycle with AI-powered simulation.

Talk to an expert

Drastically reduce the number of physical prototypes needed, saving on material, manufacturing, and lab testing costs.

Use simulation to optimize material selection and eliminate over-engineering, lowering the bill of materials for the final product.

By compressing project timelines and reducing upfront investment in physical testing, you can bring profitable products to market faster.

Minimize physical waste and optimize designs for material efficiency, contributing to both your budget and your environmental goals.

How it works

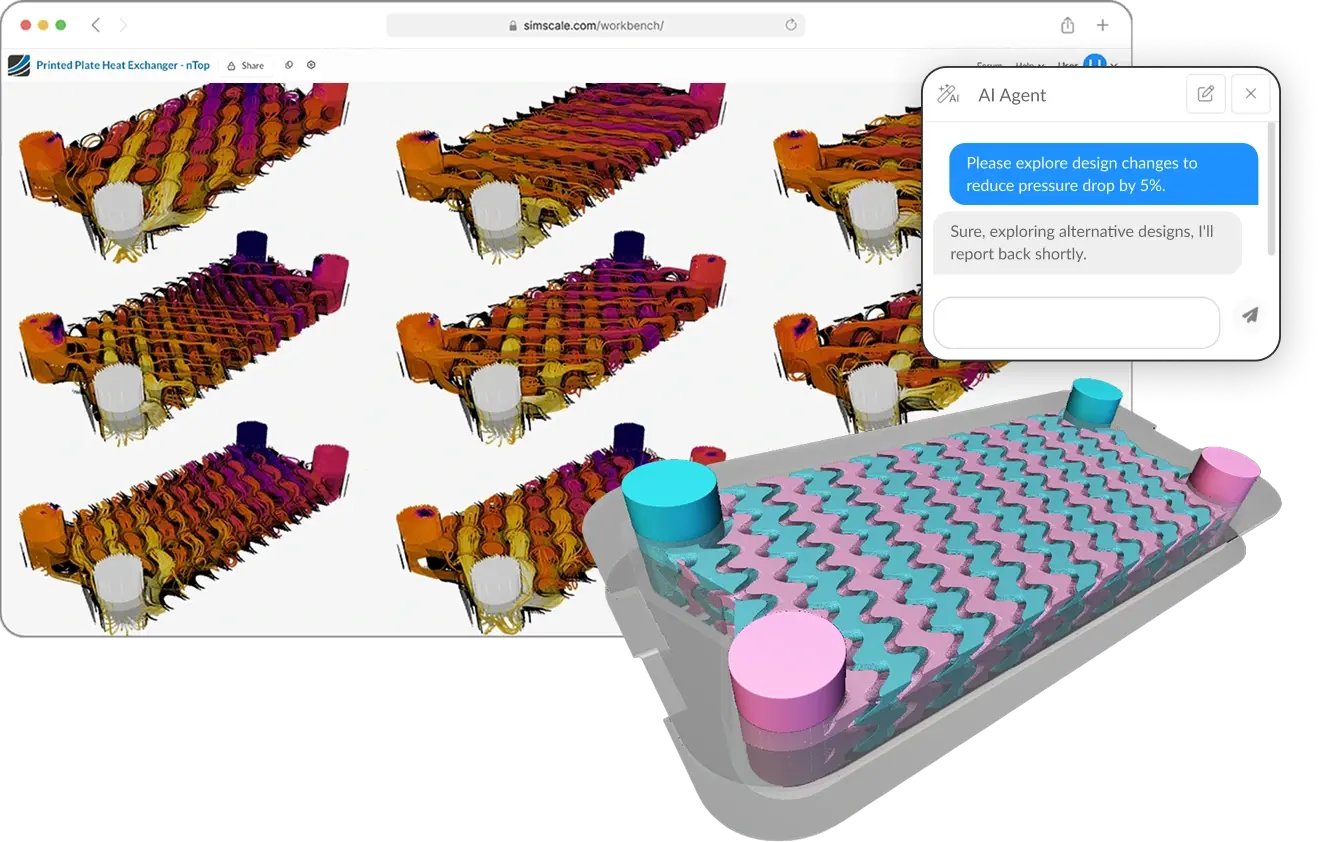

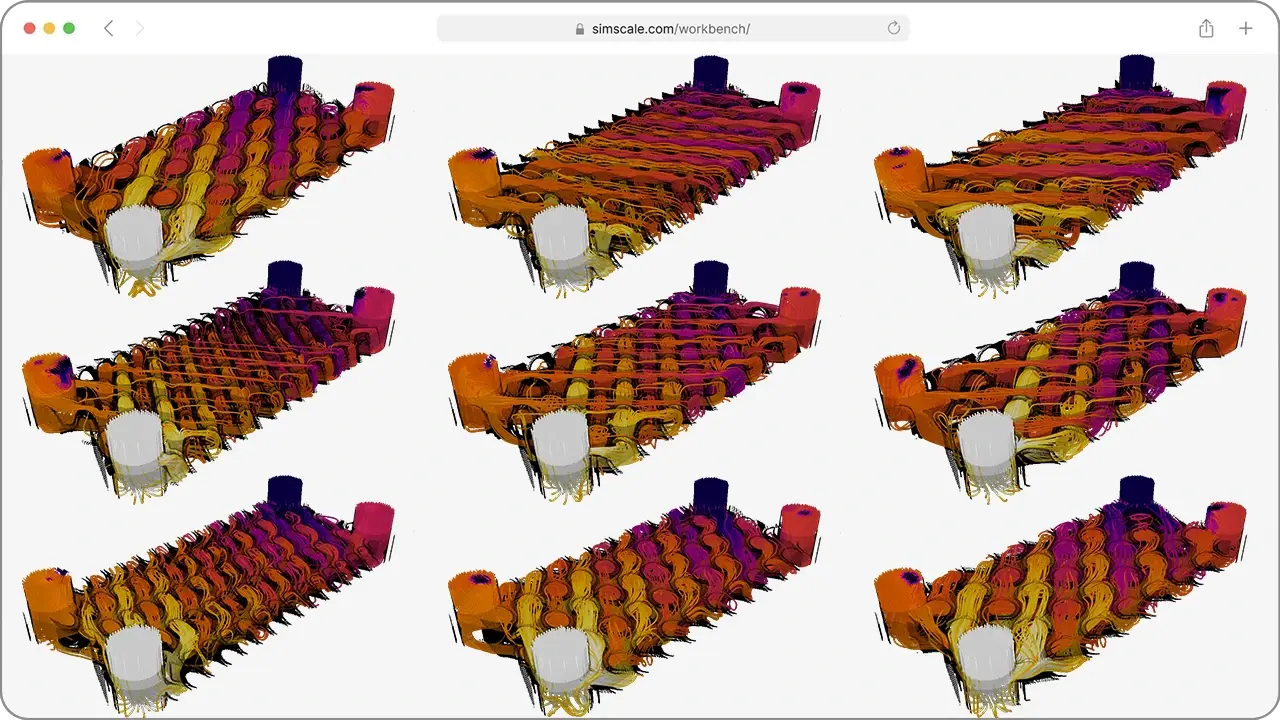

Replace costly and time-consuming physical prototypes with rapid virtual testing in the cloud. Explore and validate dozens of design iterations in the time it would take to build a single physical model, drastically reducing material and lab costs and quickly bringing the most promising design options into focus.

Leverage Physics AI to run automated studies that identify the most cost-effective designs and materials without sacrificing performance or safety. Balance weight, strength, and cost to find the optimal choice for your design and budget.

Identify and resolve potential product failures before committing to expensive tooling and manufacturing. Use simulation to understand stresses, vibrations, and thermal issues early, preventing costly late-stage redesigns, warranty claims, and damage to your brand reputation.

Run hundreds of design scenarios in parallel at a fraction of the time and expense of on-premise hardware. Eliminate HPC bottlenecks and data storage costs, allowing your team to explore more options and find savings faster.

“SimScale drastically changed our R&D landscape regarding time (99.9% quicker), cost (no HPC and data storage) and simulation accuracy. It allows us to complete development cycles within days instead of months which gives us a massive advantage to our competition. I would say that this software is not evolutionary but rather disruptive.”

Benjamin van der Walt

Engineering Manager at Hazleton Pumps International (Pty) Ltd

Sign up for SimScale

and start simulating now