Pura, the leader in innovative smart fragrance technology, leveraged Computational Fluid Dynamics (CFD) from SimScale to design and optimize its newest product, the Pura Car Pro. This car fragrance diffuser combines performance, durability, and diffusion of fine fragrances, achieved through advanced engineering simulations and iterative prototyping. By utilizing CFD and Finite Element Analysis (FEA), Pura was able to accelerate development, minimize costs, and achieve exceptional results in the final product.

“We have been using SimScale to develop new smart fragrance technology for the home and vehicles. The workflow from Onshape to SimScale is truly seamless and has helped us to innovate rapidly. Before, we used traditional desktop CAD and simulation tools, which, in hindsight, were a major obstacle to innovation. My team and I can run multiple CAD geometries in parallel in SimScale to evaluate airflow, pressure drop, and room air diffusion at once to quickly converge on a near-final product variant. Because of this, our 3D printing and physical testing costs have dropped, helping us save thousands of dollars and several days on each iteration. We have used the FEA solver for impact/drop tests and want to start using the new electromagnetics solver in SimScale to further analyze our devices.”

Jared Raulston

Senior Mechanical Engineer at Pura

The design and optimization of the Pura Car Pro™ Smart Fragrance Diffuser involved addressing several engineering challenges:

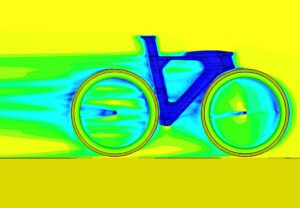

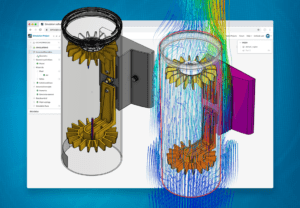

Pura used SimScale’s cloud-based platform to simulate airflow through the Car Pro fragrance diffuser and assess its performance in a typical family car interior. The car model was taken from SimScale’s extensive public projects library, which contains thousands of simulation projects that can be used. Pura first simulated air entering the diffuser, passing through fragrance media, and exiting through four internal duct designs to identify the most efficient configuration. Pressure drops and velocities were evaluated to ensure optimal performance of multiple vent and duct designs.

The team then moved to vehicle/room-level diffusion modeling, using particle tracing and passive scalar techniques to simulate fragrance diffusion across a 3D car interior. Measurements were taken over the entire 3D model volume to ensure even distribution of the fragrance. The blower fan inside the device was tested by approximating output with a momentum source. This approach simplified simulations while maintaining accuracy, allowing Pura to assess the impact of fan speeds and axial vs. blower fan designs. The team has also used the fan-performance curve method in SimScale to evaluate fan manufacturers’ performance data before selecting final components.

CAD models were designed in Onshape and seamlessly imported into SimScale for simulation. This marked a shift from SolidWorks to Onshape, which was chosen for its cloud-native collaboration capabilities with SimScale. Once the optimal design was selected based on simulation data, Pura used 3D printing to produce prototypes for physical testing. This hybrid workflow of simulation and rapid prototyping reduced iteration cycles significantly.

Durability testing ensured the product could withstand typical handling and drop impacts. Early prototypes showed fractures during drop testing. FEA simulations identified stress concentrations, enabling Pura engineers to strengthen the design with support ribs while keeping manufacturing costs low.

The team achieved even diffusion throughout the car by selecting the best duct architecture from four tested designs. The pressure drops and airflow velocities met design goals for quiet operation and efficient fragrance delivery. This was validated with excellent agreement from physical testing using smoke pens and pressure/flow measurement equipment.

Simulation reduced the need for physical prototypes, saving hundreds of dollars per 3D-printed iteration. The team could virtually test designs within hours, accelerating the development timeline by several days per iteration.

The ability to run parallel simulations on SimScale allowed Pura’s team to work on multiple designs simultaneously, significantly increasing productivity. The animations and visual outputs from SimScale were shared with stakeholders for better communication and decision-making.

Sign up for SimScale

and start simulating now