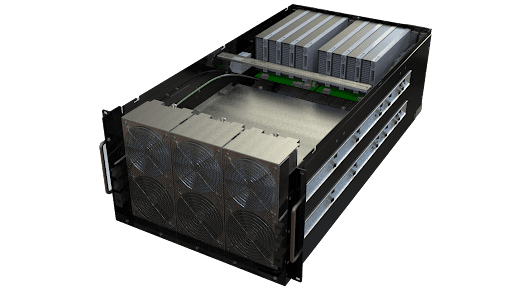

One Stop Systems, Inc. (OSS) designs and manufactures innovative edge computing modules and systems for AI Transportable applications including ruggedized servers, compute accelerators, expansion systems, flash storage arrays and Ion Accelerator™ SAN, NAS, and data recording software. These products are used for AI data set capture, training, and large-scale inference in the defense, oil and gas, mining, autonomous vehicles, and rugged entertainment applications. Edge Computing is a high-performance industry requiring efficient components and sub-systems that are optimized using engineering simulation.

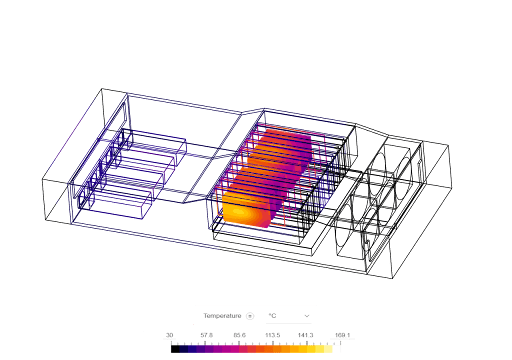

Christian Powell wears two critical hats at OSS—Mechanical Engineer and Project Manager—bridging the gap between Product Marketing and Engineering. His role isn’t just about designing new products; it’s about envisioning the future of high-performance computing and bringing it to life. With OSS components like servers operating in extreme environments and generating ever-increasing heat, thermal performance isn’t an afterthought—it’s a fundamental design challenge. To stay ahead, Powell and his team integrate thermal performance considerations from the very first stages of development, ensuring their products can withstand the harshest conditions by reducing overheating risk and shortening development time. The team also leverages the structural analysis solvers in SimScale for the ruggedization of its components.

Enter SimScale’s thermal simulation tools—a game-changer for OSS engineers. By simulating heat dissipation and structural integrity early in the design process, they can validate concepts faster, minimize overheating risks, and accelerate development timelines. Additionally, SimScale’s structural analysis solvers aid in ruggedizing OSS components, ensuring they meet the demands of high-stress environments.

“SimScale has enabled our engineers to make informed design choices earlier in the design cycle than ever. Furthermore, we are able to move forward with prototyping and testing with higher confidence in the design’s ability to meet its requirements. We may spend more time earlier in the design process running simulations, but we are ultimately able to reduce the costs associated with test failures and redesign.”

Christian Powell

Project Manager and Mechanical Engineer at One Stop Systems

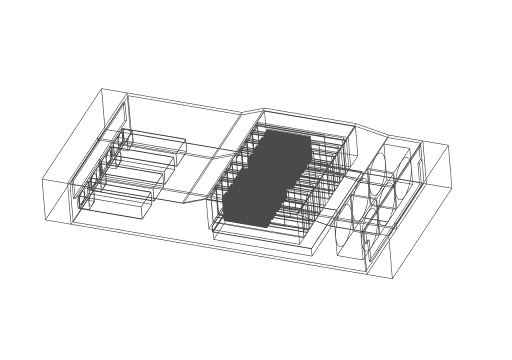

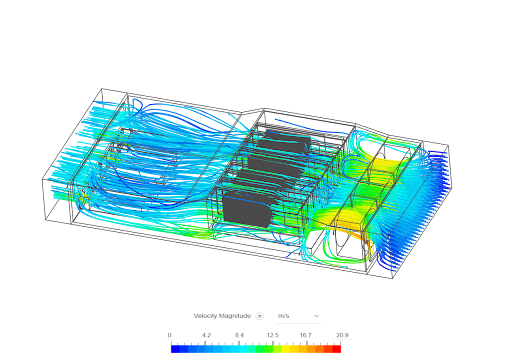

A recent example is an electronics cooling simulation using SimScale to understand fan performance and cool down components using various types of heat sinks, fan flow rates, and component layouts. In this example, 400 Watts of heat needs to be dissipated at 30℃ ambient conditions using fans (flow direction is from right to left). The device is a cooling unit for servers and contains proprietary types of heat sinks. The full model in SimScale includes dozens of component configurations, heat sink shapes/sizes, and fan performance curves to simulate real-world performance.

“We are able to provide our customers with performance specifications early on in the design process, enabling our businesses to flow. SimScale’s top-tier support team has enabled us to troubleshoot our simulations and get results with great speed. This enables us to run more simulations quickly and accurately. The ability to run simulations in the cloud means we can run multiple simulations in parallel, rather than in sequence on our local systems which used to be a major bottleneck for product development.”

Christian Powell

Project Manager and Mechanical Engineer at One Stop Systems

Sign up for SimScale

and start simulating now