The transition to electric mobility faces a critical bottleneck: a reliance on rare earth materials needed to produce permanent magnets for the synchronous radial flux motors found in today’s EVs (electric vehicles). Despite the supply chain volatility and environmental extraction costs, permanent magnets are considered essential to achieve the motor torque and efficiency requirements of a modern EV – performance that asynchronous radial flux (induction) motors cannot match.

Founded in 2023 and headquartered in Hersbruck, Germany, Emil Motors sees things differently. The company was established with a singular mission: to resolve the EV industry’s critical dependency on rare earth materials. Their disruptive motor design uses an axial flux configuration to elevate induction motor technology to match the power density of conventional permanent magnet machines.

Maximilian Güttinger, Co-Founder and CEO, drives the company’s simulation-led engineering strategy. Before founding Emil Motors, he studied mechanical engineering at the Technical University of Munich (TUM). Realizing the sudden shift in the automotive market and the immediate opportunity for sustainable powertrains, Maximilian and his co-founder Johannes Unhold made the bold decision to drop out of university to pursue the venture full-time.

Emil Motors’ Segmented Axial Flux Asynchronous Motor (SAM) is a sustainable, cost-effective “drop-in” replacement for permanent magnet motors. By utilizing a Dual Rotor, Central Stator configuration with an aluminum induction cage, the SAM delivers 330 kW and 450 Nm of torque in a package weighing just 35 kg—all without a single gram of rare earth material.

To make an induction motor competitive with the best permanent magnet motors, the team had to overcome the inherent thermal, mechanical, and electromagnetic disadvantages of induction technology. As Maximilian explains, “Developing a product like this from scratch requires a lot of simulation work across multiple physics to explore all of the possibilities in the design space.”

Emil Motors needed a professional-grade solution that integrated seamlessly with their CAD workflow in Onshape. This led them to SimScale. The platform’s cloud-native architecture allowed the team to import geometry directly from Onshape and run massive parallel simulations across thermal, structural, fluids and electromagnetics domains via a web browser. “Getting speed, accuracy, usability, and cost efficiency in one package is hard to find anywhere else.” Maximilian notes, “Being cloud-based, SimScale makes it easy to get the work done, and the interface and ease of use is better than most of the legacy software out there.”

“One significant advantage of SimScale is the ease of use, especially with Onshape. The CAD can be adapted quickly and ideas can be explored with great detail at an early stage. It takes the legwork out of design exploration and optimization.”

Maximilian Güttinger

CEO & Co-founder, Emil Motors

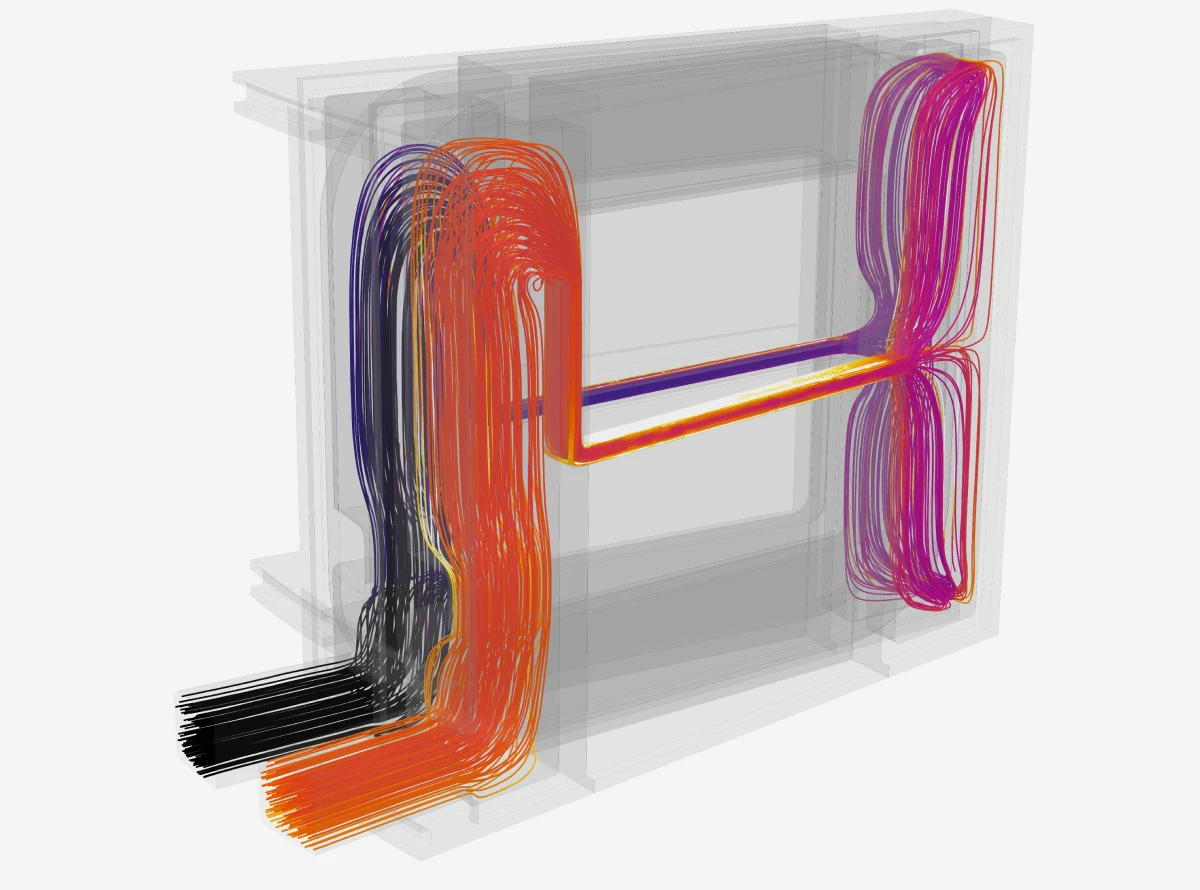

Early in development, the team hypothesized that standard external cooling would be insufficient for the amount of Joule heating in the stator, especially with the dual rotor design restricting access. Using SimScale’s Conjugate Heat Transfer (CHT) capabilities, they developed a radical “Direct Oil Cooling” concept. The design features a segmented stator dozens of individual sections, each containing integrated channels where transmission oil flows directly against the insulated copper coils.

The team simulated the 3D fluid dynamics to optimize the hydraulic pressure balance across the different cooling channels to ensure uniform cooling throughout the stator. This process involved navigating many tradeoffs, as Maximilian recalls: “A critical aspect was the sizing of the internal channel through the iron core, allowing fluid to flow from one side of the rotor to the other. A wider channel provides better cooling but reduces the efficiency of the stator core by removing ferrous material.”

The results were transformative: the simulation predicted the motor could run at 50% of peak torque (approx. 200 Nm) continuously while keeping coil temperatures below 100°C—a massive 40-degree reduction compared to the industry standard of 140°C. Physical testing later confirmed these thermal predictions to be within 99% accuracy.

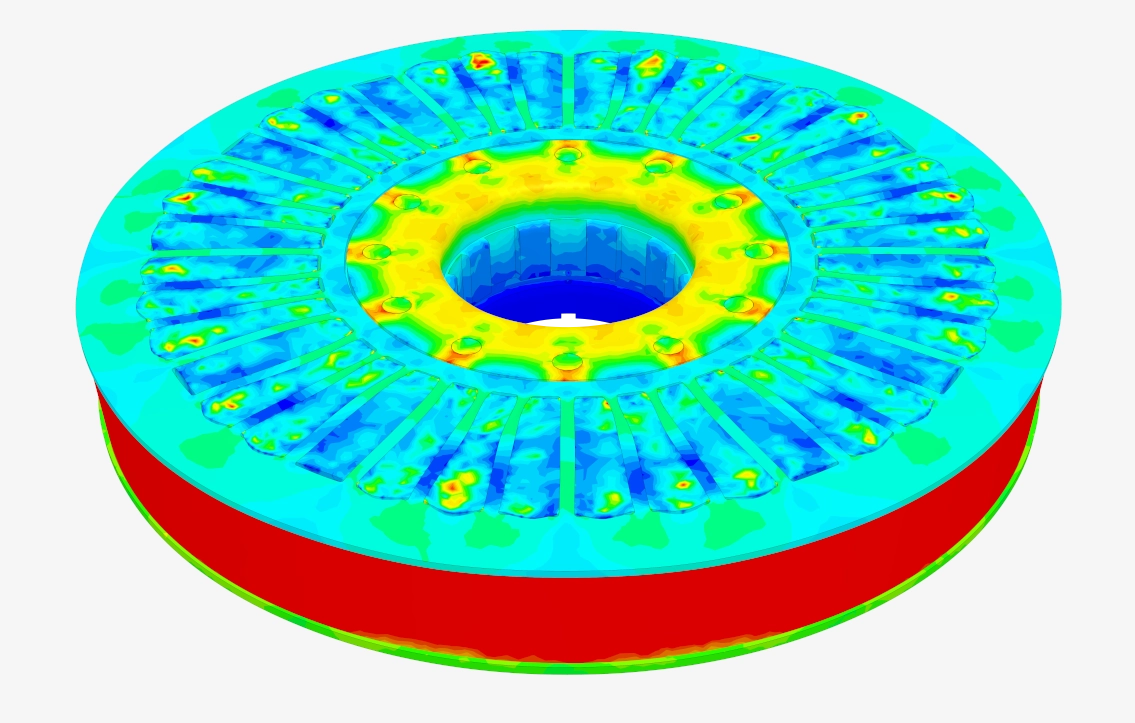

To compensate for the lack of strong magnetic flux from rare earth magnets, the SAM design must spin faster to generate equivalent power. Reaching the target speed of 16,000 RPM exerts extreme centrifugal forces on the 300 mm diameter rotors and because of the small air gaps needed in axial flux machines, rotor deformation under load has to be very carefully managed.

The team used Finite Element Analysis (FEA) in SimScale to guide the design of the rotor assembly and explore ways to achieve their target operational speed without exceeding the limits of the materials. FEA initially showed stresses in the outer retaining ring exceeding 1,000 MPa, predicting that steel would fail and necessitating a carbon fiber sleeve. By iterating through more than 20 geometries, the team optimized the adhesive bonding strategy between the aluminum and steel to stiffen the structure and control this bending motion.

FEA simulations also revealed that, due to the mass distribution of the heavy iron core relative to the aluminum spokes, centrifugal forces caused the rotor discs to “dish” away from the central stator at high speeds. Maximilian explains, “This was a very helpful discovery, since it effectively works as a self-governing mechanism to prevent contact between the rotors and stator. It’s a critical consideration with an air gap of only 0.6mm”

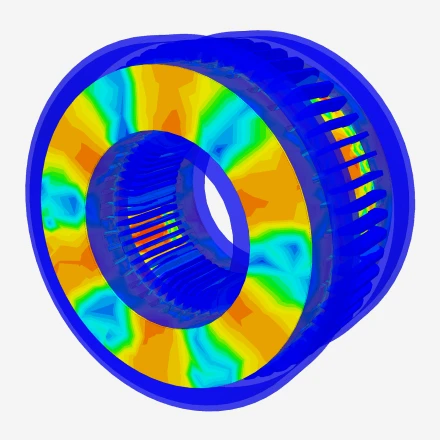

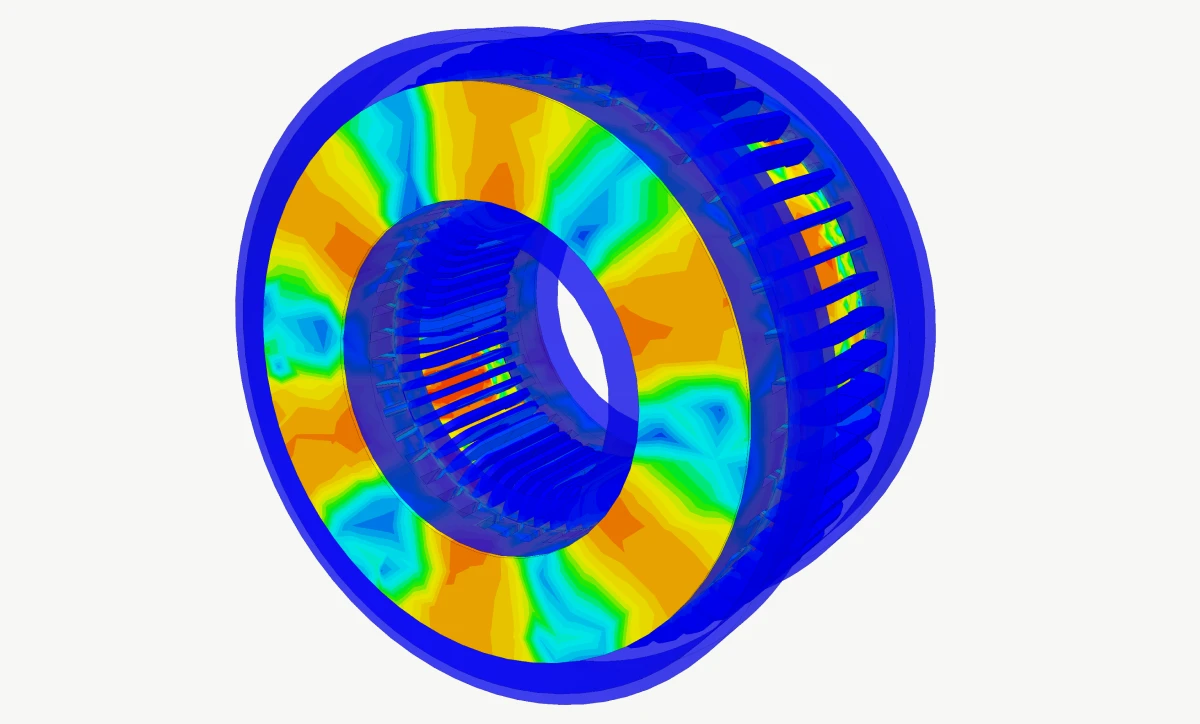

While Emil Motors employs 2D simulation tools for rapid iterative sizing, they rely on SimScale to solve complex 3D electromagnetic phenomena that are critical to the machine’s efficiency.

The team utilized 3D “no-load” simulations to visualize the magnetic flux distribution within the iron core. This allowed them to precisely size the stator teeth and iron back-iron. If the iron is too thin, the magnetic flux saturates , choking performance. If too thick, the motor becomes heavy and sluggish. By mapping the flux density in 3D, Emil Motors identified the exact material threshold, trimming excess iron to minimize weight without compromising magnetic saturation.

The most critical value of 3D simulation lay in identifying “stray losses” – locations where magnetic fields leak out of the active core and pass through nearby structural components like the housing, the backplate, and the shaft. “If you make those parts from standard mild steel, they are magnetic,” Maximilian notes. “They can actually have a significant effect on the machine.”

When the leaking magnetic field hits these conductive parts, it induces unwanted eddy currents, which generate heat without contributing to torque. Because these components are geometrically complex and sit outside the 2D plane, these losses are invisible in 2D simulations. SimScale’s 3D analysis generated a “heat map” of losses, revealing exactly which structural components were absorbing energy. This insight allowed the team to modify the housing geometry, increasing the air gap between magnetic parts and the case, and switch specific components to non-magnetic materials, effectively neutralizing these parasitic losses.

Another source of loss to be quantified is aerodynamic drag on the rotors. At 16,000 RPM, the air inside the motor behaves less like a gas and more like a viscous fluid. This creates “windage loss”—drag that resists the rotation of the rotor.

Maximilian performed internal aerodynamic simulations to measure this effect and to understand how to mitigate it. Simulation results showed that a smaller gap between the rotor and outer casing resulted in lower turbulence levels in the annular space, with a corresponding lower drag force on the rotor. This led the design team to minimize the clearance around the rotors as part of the push for overall motor efficiency. As Maximilian notes, “to achieve our goal of matching the efficiency of permanent magnet motors, we look to optimize every aspect of the motor, whether that is in the electromagnetic design, thermal management, mechanical or aerodynamic.”

The strategic adoption of SimScale allowed Emil Motors to condense years of R&D into a streamlined, cloud-native workflow. By integrating SimScale directly with Onshape, the team achieved a 2x speed up in iteration cycles, moving from CAD to simulation results seamlessly. In October 2025, the company announced the successful hardware validation of its prototype, a milestone that proves the SAM architecture is an industrial reality.

“If we didn’t use simulation to the extent that we’re using it, we would have to build at least one more full prototype. That would be tens of thousands of euros more. And ultimately, you can’t improve a design if you don’t understand the effects that are defining performance.”

Maximilian Güttinger

CEO & Co-founder, Emil Motors

Looking ahead, Emil Motors is using these validated simulation models to push the design from its current 12,000 RPM test limits toward the ultimate 16,000 RPM target. By solving thermal, structural, and electromagnetic challenges in parallel, they have engineered a motor that can break the industry’s dependence on rare earth materials, securing a more sustainable future for the electric vehicle industry.

Set up your own cloud-native simulation via the web in minutes by creating an account on the SimScale platform. No installation, special hardware, or credit card is required.

Sign up for SimScale

and start simulating now