For nearly half a century, Crestline Coach has been a leader in manufacturing safe, durable, and innovative emergency vehicles. The company’s core mission is to support first responders and patients by providing highly reliable and customized ambulances. This commitment to bespoke design, however, creates a significant engineering challenge: every modification to a vehicle’s interior alters its thermal dynamics, requiring rigorous validation of the Heating, Ventilation, and Air Conditioning (HVAC) system.

Designing an ambulance’s climate control is a complex balancing act. The system must meet stringent industry standards while accommodating the conflicting needs of a patient who may require warmth, paramedics in heavy gear who need to stay cool, and temperature-sensitive medical supplies.

In the ambulance industry, where lives are at stake, the vehicles we design are not just products—they are critical tools for first responders. If our engineering falls short, it directly impacts the care a patient receives in their most vulnerable moments.

Bihara Singh, Automotive HVAC Product Engineer

Bihara Singh, an Automotive HVAC Product Engineer at Crestline Coach, is a Mechanical Engineer with a Master’s degree specializing in fluid mechanics and Computational Fluid Dynamics (CFD). With over four years of experience in automotive HVAC systems and thermal management system design, Bihara plays a crucial role in optimizing the design and performance of emergency vehicle climate control systems.

Previously, Crestline’s design process was anchored by physical prototyping, a method that was both expensive and slow, often taking weeks for a single iteration. This approach offered limited insight into why a design failed, as the complex, three-dimensional airflow patterns and heat transfer effects remained invisible. A failure would trigger another lengthy and expensive cycle of modification and re-testing, hindering progress.

With our traditional prototyping method, we were essentially designing in the dark. We’d build a full-scale model based on experience and hope for the best. The data we could gather was minimal, and a failure meant weeks of delays and significant cost.

Bihara Singh, Automotive HVAC Product Engineer

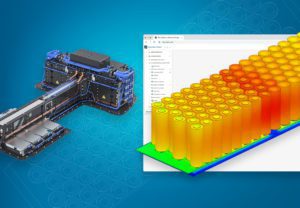

The strategic need to accelerate time-to-market while improving product performance led Crestline to seek a new solution. The company chose SimScale’s cloud-based simulation platform for its accessibility, ease of use, and the ability to run multiple simulations in parallel without requiring high-performance computing hardware.

The adoption of SimScale transformed Crestline’s workflow, shifting critical analysis from a late-stage bottleneck to an integral part of the early design process. When asked what makes working in the cloud a different experience, Bihara highlighted the speed and confidence with which he is able to make decisions.

SimScale was a complete paradigm shift. Suddenly, we could see everything—every vortex, every hot spot, every dead zone—on our screens within hours. It allowed us to move from a process of trial-and-error to one of true data-driven, predictive engineering.

Bihara Singh, Automotive HVAC Product Engineer

When working on time-critical projects, Bihara also appreciates the near-immediate technical support that SimScale users can access directly in the platform, commenting “it is great to be able to message support directly, share my project and get help in 15 minutes or so – I’ve never encountered that level of support before. It’s valuable since no matter how experienced you are with simulation, there will always be new challenges.”

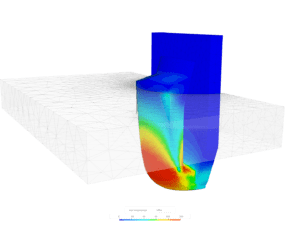

During the development of a new ambulance model, designed to accommodate multiple casualties and operating in the extreme winter environment of Ontario, Bihara was faced with an engineering challenge. The vehicle needed to be capable of warming up the cabin from –35 °C ambient temperature to a patient-ready +22 °C in under 30 minutes, placing high demands on the HVAC system.

“In larger vehicles, the engine’s waste heat is insufficient to meet warm-up performance targets, requiring an auxiliary, fuel-fired heating source to be added,” explains Bihara. “However, this heater produces air at a dangerously high temperature if blown directly into the cabin. To deliver a comfortable and precise temperature, this hot air must first be blended with cold ambient air.”

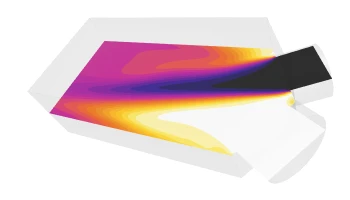

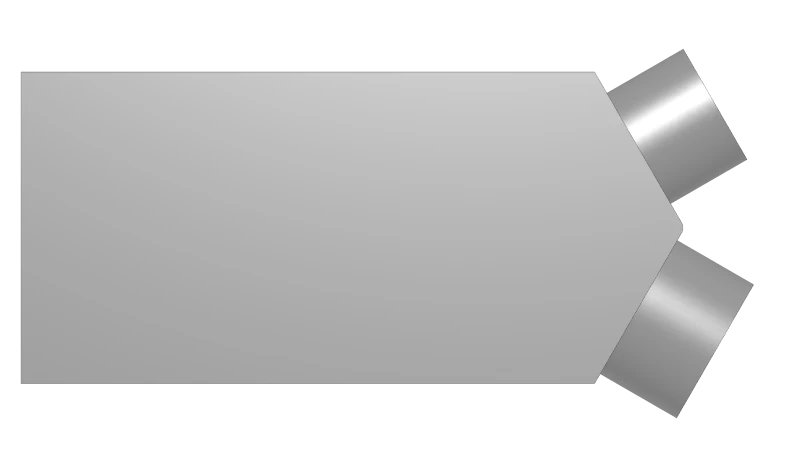

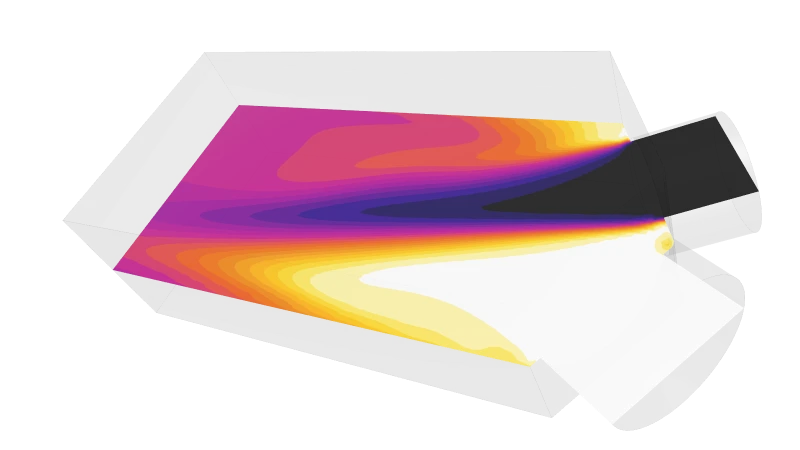

The engineering challenge was to design a compact mixing conduit that could achieve a thermal mixing efficiency of over 80% while keeping pressure drop to a minimum. The design was constrained by the extremely limited space available inside the vehicle and the need for a simple manufacturing process with no moving parts. Taking inspiration from the aerospace industry, Bihara used the principle of controlled vortices to induce rapid mixing in the confined physical space available.

Using Convective Heat Transfer analysis in SimScale, he rapidly explored 16 design iterations, varying parameters like the offset and angle of the inlets to optimize the vortex position and the resulting temperature uniformity. “The ability to run simulations in concurrent batches allowed the entire virtual development process to be completed in just three to four weeks, in between other work —a fraction of the months it would have taken to build and test physical prototypes”, says Bihara. The final design for the novel vortex-based mixer achieved a thermal effectiveness of over 80%, ensuring patient comfort and safety even in the harshest winter conditions.

The integration of SimScale yielded dramatic and measurable improvements. By replacing the iterative physical prototyping cycle with rapid virtual testing, Crestline reduced the design and validation phase for the new HVAC system by 30%.

This accelerated timeline was accompanied by substantial cost savings. The ability to identify and resolve critical design flaws early and virtually eliminated the need for several physical prototype builds, translating into a 60% cost saving overall. Crucially, the final physical prototype passed all performance criteria on the very first test, a testament to the high fidelity and predictive accuracy of the simulation-led process.

Looking to the future, Crestline sees simulation as key to addressing the industry’s evolving roadmap, which has expanded from a primary focus on patient safety to include major new initiatives in efficiency and occupant comfort.

To tackle efficiency, the team plans to use SimScale for external aerodynamics, a direct response to a growing demand from government fleet managers to reduce fuel consumption. Beyond aerodynamics, Crestline is actively developing innovative energy-saving solutions, such as a battery-powered HVAC system that allows climate control to continue running even when the vehicle’s engine is off. This will significantly reduce fuel waste from ambulances that are often left idling for long periods.

To improve comfort, the company plans to deploy simulation to predict and mitigate HVAC noise, a major source of discomfort in the cabin, by optimizing ductwork to reduce the noise generated by the powerful systems that are required for large ambulances.

This expansion into new physics and applications marks Crestline’s strategic shift from a traditional, test-centric model to a predictive, simulation-driven one.

Our work with SimScale gives us the ability to design smarter, test faster, and validate ideas earlier in the process. In our industry, where reliability and safety are non-negotiable, having confidence in our designs before we even build prototypes is a game changer.

Bihara Singh

Automotive HVAC Product Engineer

Sign up for SimScale

and start simulating now