Cobalt Design (Cobalt) is a product design and engineering studio based in Melbourne, Australia. Their multidisciplinary team works on projects of all sizes and industries, from consumer goods and medical devices to transport solutions and industrial equipment. Cobalt offers end-to-end product development services, including research, design, engineering, prototyping, testing, and production support. With decades of experience, Cobalt helps clients transform ideas into award-winning products that users love.

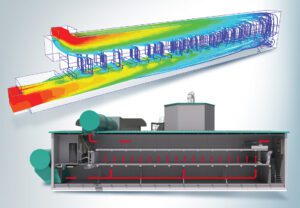

Cobalt engineers use a variety of market-leading tools and techniques, including SimScale, to quantify, optimize, and validate solutions throughout the design process to evaluate and optimize the performance of components, assemblies, and systems in a virtual environment. This allows the team to refine and reiterate designs and materials before investing in physical prototypes. The team at Cobalt used the workflow of SolidWorks and SimScale to rapidly design, test, iterate, and develop a novel swimming pool chlorinator for the domestic market.

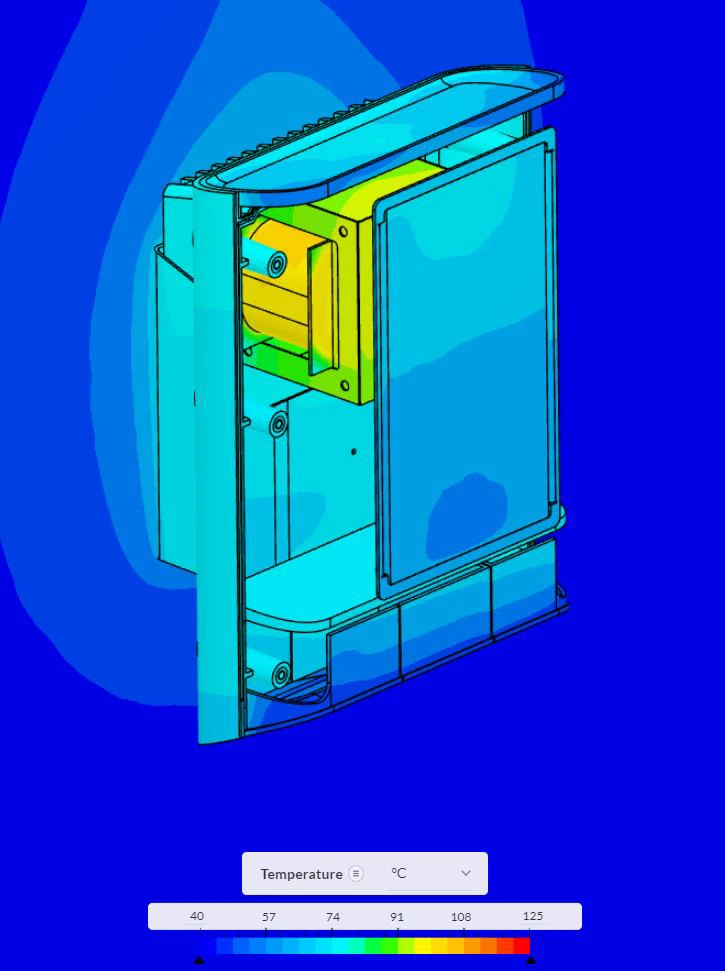

The goal of the simulation study was to test the thermal effects of a range of different design refinements that were introduced to improve performance or meet client thermal limits requirements under ambient operating conditions of 45 ℃ with the unit being mounted outdoors in direct sunlight. Davis Tolley is a product design engineer and simulation specialist in the wider engineering team and has extensively leveraged SimScale on many projects including the pool chlorinator. The most common type of analysis at Cobalt is combined thermal / flow analysis for internal cooling for products that must be kept below a certain temperature.

The pool chlorinator controller device plugs into a swimming pool chlorinator unit and controls the amount of chlorine and other chemicals released into the pool water. The unit is often mounted on outdoor walls in sunlight and is vulnerable to overheating which can cause device malfunction and failure. Current units were automatically ‘throttled’ to control temperature but this imposes performance limitations. The client had an existing product that was overheating and commissioned Cobalt to develop a new product that would maintain threshold temperatures at higher performance levels.

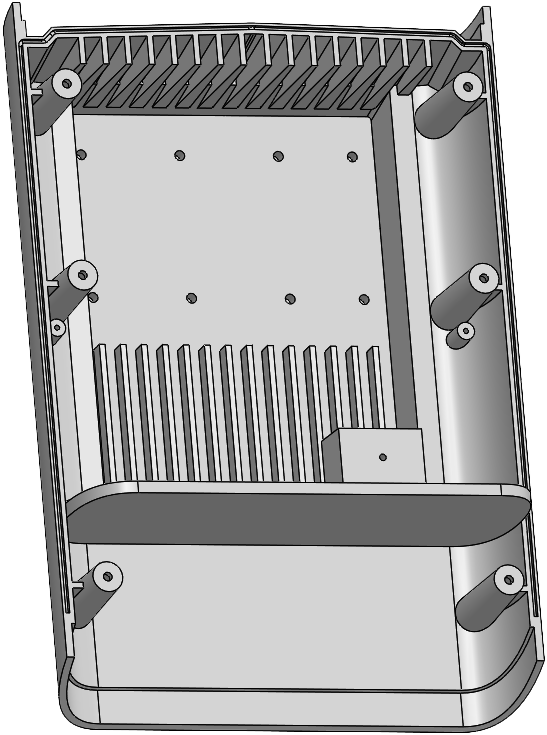

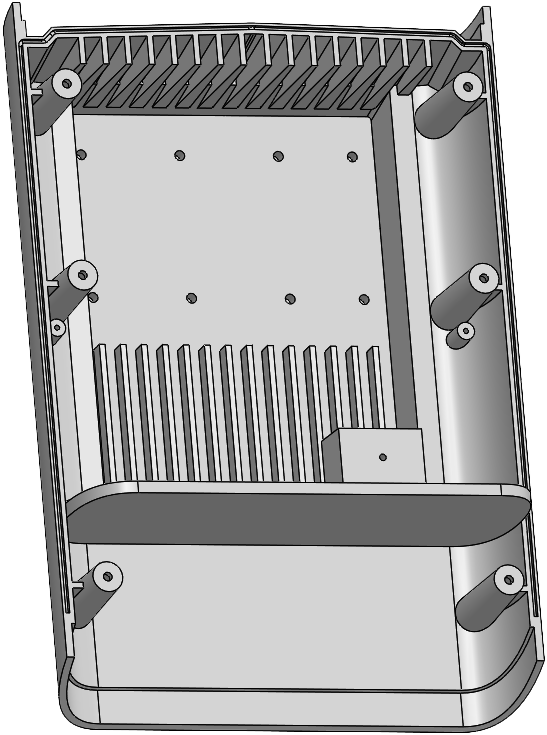

The controller is designed for brick wall mounting and has touchscreen control. The back of the unit is an Aluminum cast heat sink with a front plastic body and enclosure. The overall unit size is 400 mm in height and contains several internal electronic components. The main heat is generated from the transformer consisting of copper coils and a laminated steel core.

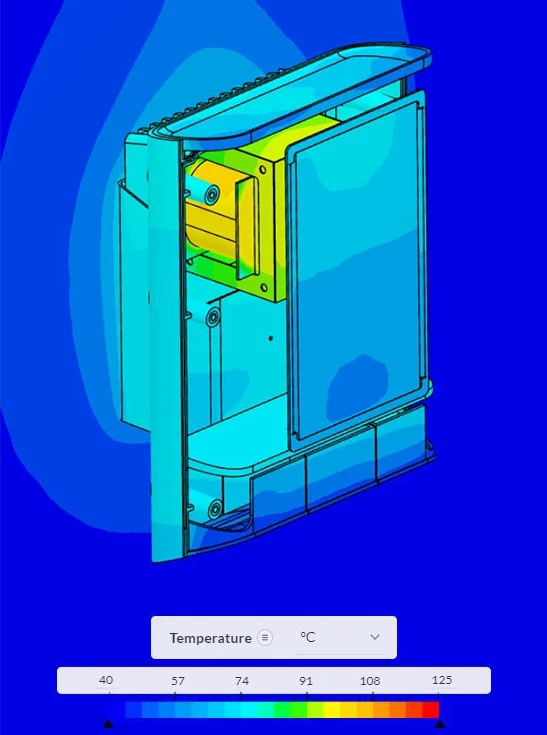

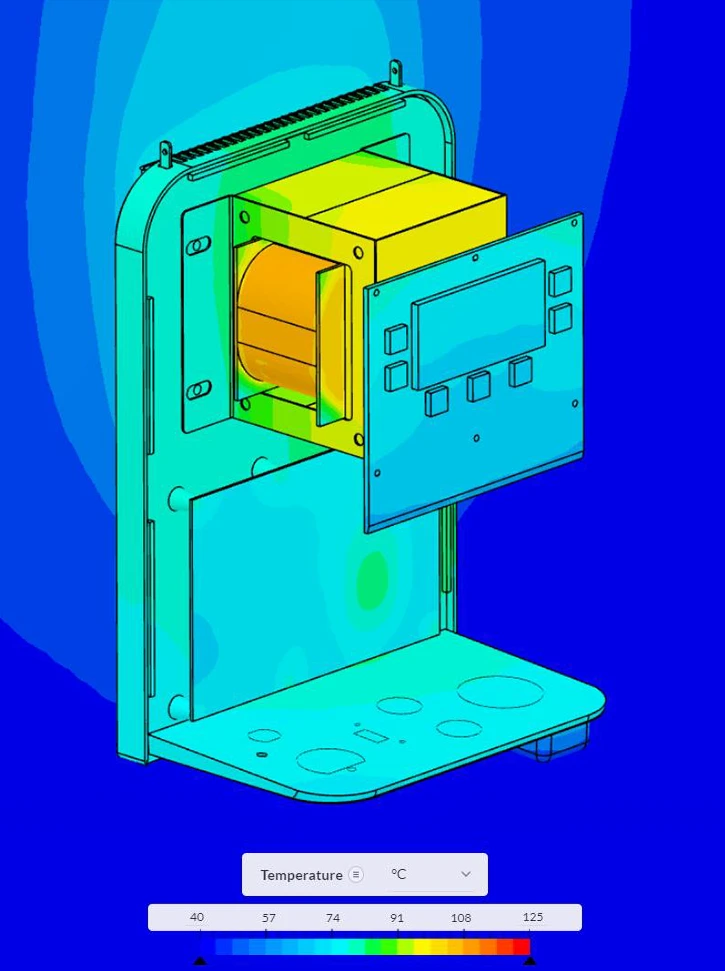

This study is about simulating an existing unit and then comparing the relative benefits to a new design. There were many reported issues in the existing units’ heat sink causing localized peak temperatures inside the unit and trapping heat without an adequate exfiltration path. These observations were also validated in the simulation of the existing unit.

The new designs made changes to the heat sink geometry and layout which reduced temperatures in problem areas and inside the unit. SimScale was especially useful for modeling the non-isotropic material properties inside the transformer where thermal conductivity is different depending on the axis of heat transfer. A rectifier mounted below a PCB also generates heat that must be carefully controlled and dissipated. Client requirements discouraged the use of cooling fans leading to a greater emphasis on larger capacity heat exchanger design and optimized layout.

A passively cooled design was successful in this case by simulating dozens of configurations of heat sink fin shape and size, internal component layout, and air intake and exhaust placements. The plastic cover on the front was modified to provide additional solar shading. Key design improvements included:

The final iteration reduced temperatures in all areas of the device and peak temperature from 109℃ down to 104℃ inside the transformer and from 80℃ down to 71℃ inside the heat sink. The proprietary design has advanced to the tooling stage and at the time of writing is about to enter production at scale.

One of the biggest benefits of using SimScale is that it is cloud-based. We can run massive simulations and not need a local HPC setup that frees up our computational resources and time. We have observed faster solve times compared to legacy desktop software tools and the user interface is intuitive with a shallow learning curve. In the swimming pool chlorinator project we were able to reduce internal temperatures by 11% inside the heat sink and move to the physical testing and production stage much faster as a result.

Davis Tolley

Product Design Engineer at Cobalt Design

Sign up for SimScale

and start simulating now