In our recent webinar, our application engineering team dove deep into the transformative realm of electromagnetic simulations, specifically focusing on the advanced technique of magnetic pulse welding.

As pioneers of cutting-edge, cloud-native simulation solutions, SimScale is dedicated to democratizing access to sophisticated engineering tools, allowing teams to accelerate design decision-making and optimize performance across various industries. This session unpacked how SimScale’s platform leverages AI-enhanced simulations to streamline and enhance the electromagnetic welding process, making it more accessible and efficient for engineering professionals.

On-Demand Webinar

If the highlights caught your interest, there are many more to see. Watch the on-demand Simulation Expert Series webinar from SimScale on how real-time simulation with AI is driving faster design cycles and superior products by clicking the link below.

1. Effortlessly Analyze Core Electromagnetics

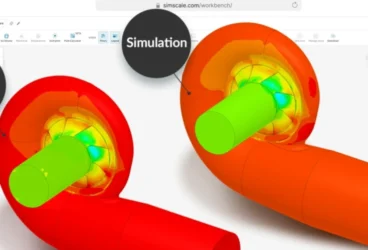

Tackle computationally heavy transient simulations with ease using SimScale’s cloud-native platform. The webinar shows how on-demand computing power removes hardware limitations , allowing you to accurately analyze magnetic field distribution and eddy current density from your web browser. An integrated AI assistant can also guide you through the setup process, making complex analysis more accessible.

2. Accurately Predict Welding Forces

Learn how to predict the critical Lorentz forces that create the weld without melting the materials. The webinar demonstrates how SimScale’s high-fidelity results provide the insight needed to assess the effectiveness of the magnetic impulse. You can then instantly share these results with your team using a simple URL link, streamlining review and decision-making.

3. Manage Thermal Effects with Confidence

The high-intensity current pulse generates significant Joule heating, even in a microsecond-long event. Discover how to run a coupled thermal-magnetic analysis to visualize these heating effects and ensure temperatures don’t compromise material properties. If you need assistance, the platform’s integrated support chat provides expert advice in minutes.

4. Rapidly Optimize Your Design

See how the cloud enables rapid design optimization by running a limitless number of parallel simulations to explore a wide design space. The webinar shows how to easily compare different coil geometries, materials, and air gaps to improve weld consistency. This ability to iterate quickly allows your team to innovate faster and reduce the risk of failure.

5. Democratize Simulation for the Entire Team

SimScale is built to make simulation accessible to both experts and beginners on your team. The webinar explains how this approach helps break down knowledge silos and avoid bottlenecks common with traditional simulation tools. By using pre-validated simulation templates, designers and engineers can confidently run their own analyses, fostering a more collaborative and efficient workflow.

Conclusion

This SimScale webinar illuminated the profound impacts of integrating cloud-native, AI-enhanced simulation tools in addressing complex engineering challenges like magnetic pulse welding. The insights presented underscore how SimScale is at the forefront of the technological revolution in engineering, providing solutions that are not only powerful and comprehensive but also accessible and conducive to collaborative innovation.

Watch Now

For a deeper dive into how SimScale’s groundbreaking features can significantly benefit your projects, watch the full on-demand webinar recording. Discover firsthand the detailed demonstrations and expert discussions that will equip you with the knowledge to leverage magnetic pulse welding and other advanced simulations for your applications. Click here to access the full session and start transforming your engineering workflow today.