In our recent Simulation Experts Webinar Series, we delved into the intricacies of solenoid design, showcasing how SimScale’s cloud-native simulation platform empowers engineers to enhance and optimize solenoid performance efficiently.

Led by Product Manager Nur Öztürk, the session provided valuable insights into leveraging advanced simulation techniques for solenoid workings.

If you missed the live session, here are the top five highlights from the webinar:

- Optimizing Magnetic Field Distribution for Enhanced Efficiency

- Refining Electromagnetic Actuator Design

- Improving Thermal Management and Heat Dissipation

- Reducing Material Waste and Development Time

- Validating Performance Without Physical Prototypes

On-Demand Webinar

If the above highlights caught your interest, there are many more to see. Watch the on-demand Simulation Expert Series webinar from SimScale on how real-time simulation with AI is driving faster design cycles and superior products by clicking the link below.

1. Optimizing Magnetic Field Distribution for Enhanced Efficiency

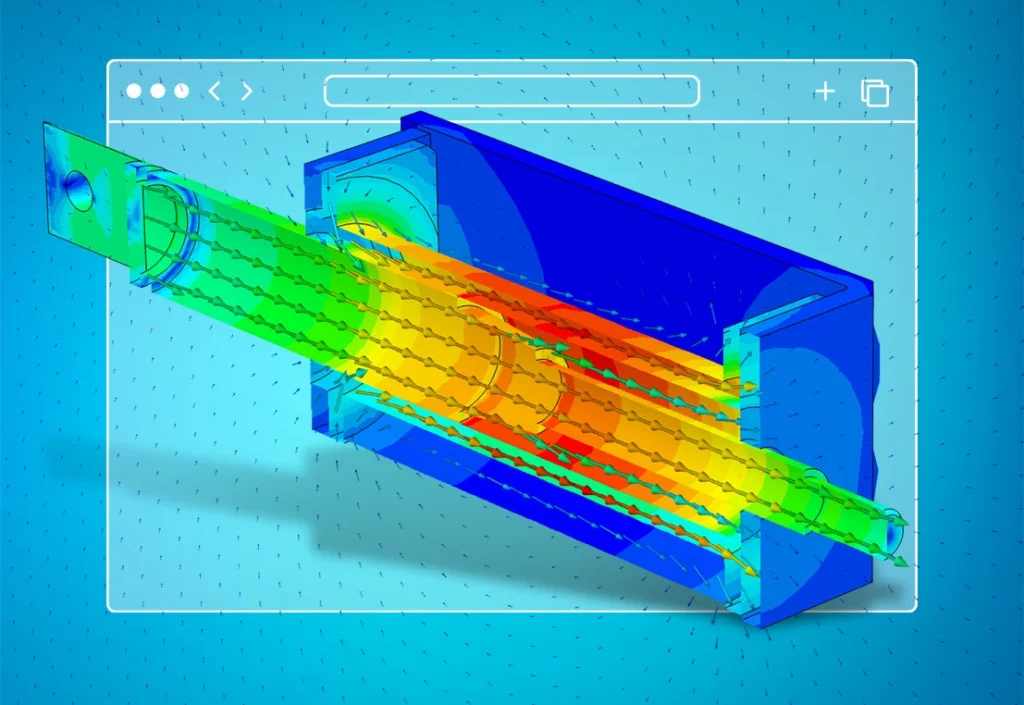

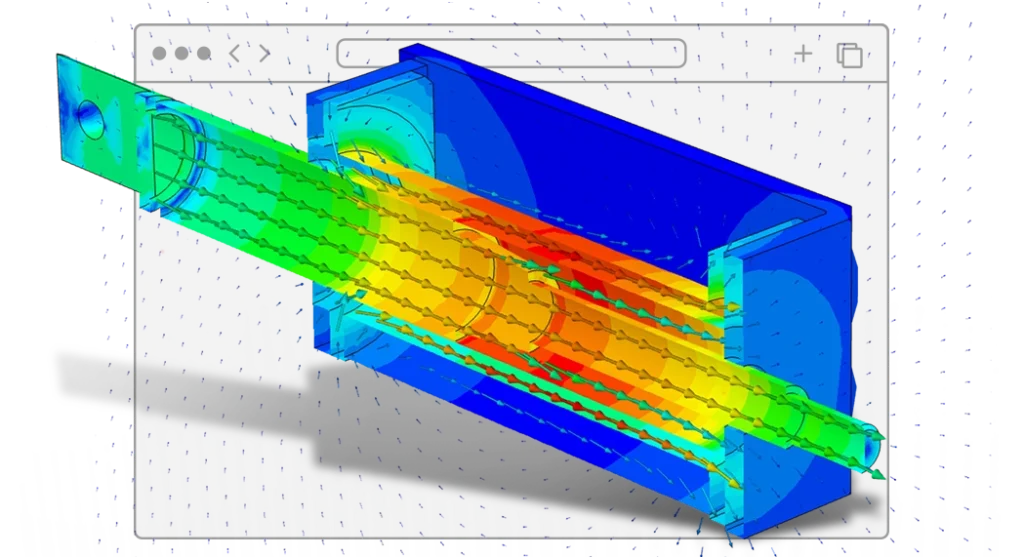

The webinar emphasized the importance of precise magnetic field distribution in solenoid design. Using SimScale’s electromagnetic simulation capabilities, engineers can visualize and adjust magnetic fields to ensure optimal performance. This approach allows for the identification of areas with magnetic saturation or leakage, enabling targeted design modifications that enhance solenoid efficiency.

2. Refining Electromagnetic Actuator Design

A key focus was on the iterative refinement of electromagnetic actuators. By simulating various design configurations, engineers can assess the impact on actuator force and response time. This process facilitates the development of actuators that meet specific performance criteria, reducing the reliance on physical prototypes and accelerating the design cycle.

3. Improving Thermal Management and Heat Dissipation

Thermal performance is critical in solenoid operation. The session demonstrated how SimScale’s thermal simulation tools enable the analysis of heat generation and dissipation within solenoid components. By identifying hotspots and evaluating cooling strategies, engineers can design solenoids with improved thermal stability and longevity.

4. Reducing Material Waste and Development Time

The integration of simulation into the design process contributes to material and time savings. By virtually testing and validating designs, engineers can minimize the need for multiple physical prototypes. This approach not only conserves resources but also shortens the development timeline, allowing for quicker iterations and faster time-to-market.

5. Validating Performance Without Physical Prototypes

The webinar highlighted the capability of SimScale to validate solenoid performance through simulation alone. By accurately predicting operational behavior under various conditions, engineers can ensure that designs meet performance requirements before any physical manufacturing. This virtual validation is particularly beneficial in industries where prototyping is costly or time-consuming.

Final Thoughts

This webinar underscored the transformative impact of cloud-native simulation in engineering. By reducing simulation lead time, breaking down silos, and integrating AI-driven insights, organizations can drive faster design cycles and superior products.

For those who missed the live session, the full webinar is available on-demand on SimScale’s website. Watch it here: Enhance & Optimize Solenoid Design with SimScale.

For further reading on solenoid design and modeling, check out our blog post: Solenoid Design and Modeling: Cloud-Native Simulation.

Stay tuned for more insights in our Simulation Experts Webinar Series!