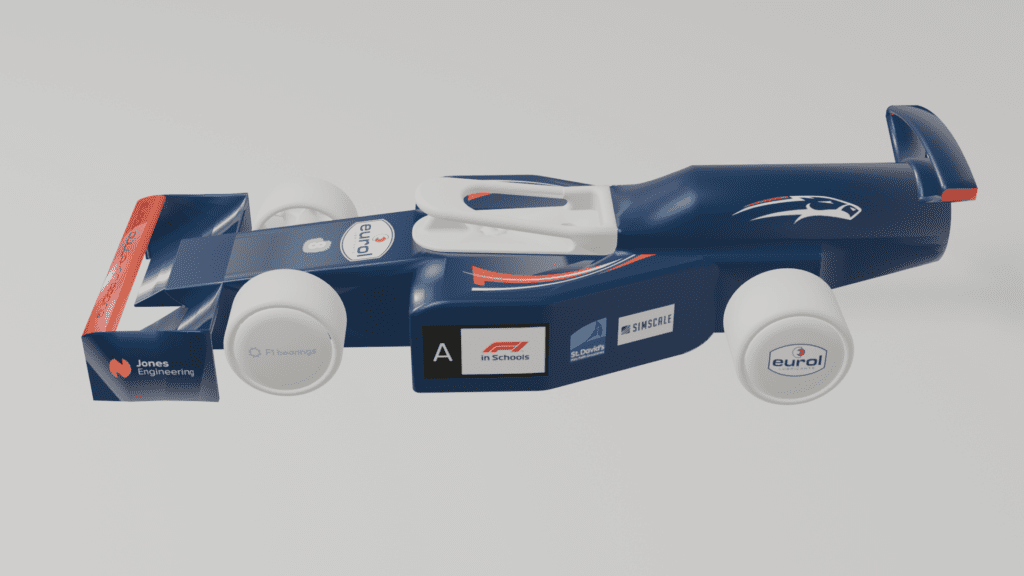

Eurol Dullahan Racing is an Irish team competing in the prestigious F1 in Schools STEM competition at both regional and national levels. Comprised of six dedicated secondary school students, the team shares a passion for motorsports and engineering, relentlessly striving to design and develop the fastest and most innovative car in the competition.

The team developed the second-fastest car in Ireland during the 2023/24 season of the competition, achieving impressive performance statistics. SimScale played a pivotal role in the design process, providing invaluable and reliable data that significantly contributed to the team’s success.

“Overall, it is fair to say that SimScale was one of the best parts of our system as it allowed us to obtain such useful and reliable data. We would be nowhere near where we are now without their help.”

– Team Statement

Design Challenges

To create the best car in the competition, continuous innovation and refinement of previous designs are essential to maintaining a competitive edge. The F1 in Schools regulations are regularly updated, adding an extra layer of difficulty by rendering past innovations obsolete and encouraging teams to develop new, unique solutions. With design possibilities constantly evolving, extensive testing during the development stages is crucial for selecting the most effective configurations without relying on costly and resource-intensive track testing. Due to limitations in manufacturing capabilities, budget, and access to testing facilities, the team depended heavily on SimScale for accurate performance insights. SimScale was chosen as the team’s CFD partner for its user-friendly interface, which allowed for efficient and effective simulations without the need for extensive training or high-end computing power.

How SimScale Simulations Led to Success

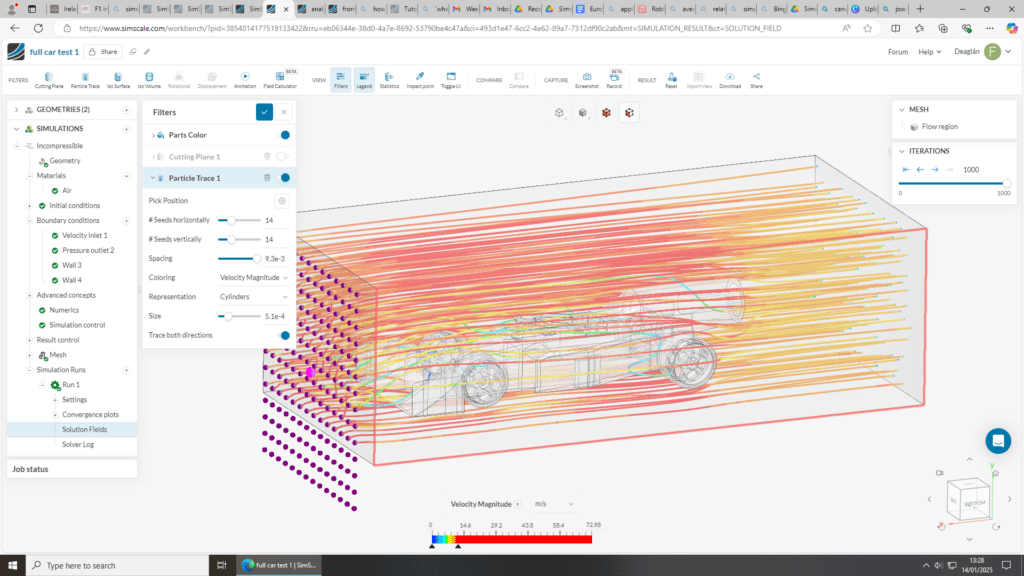

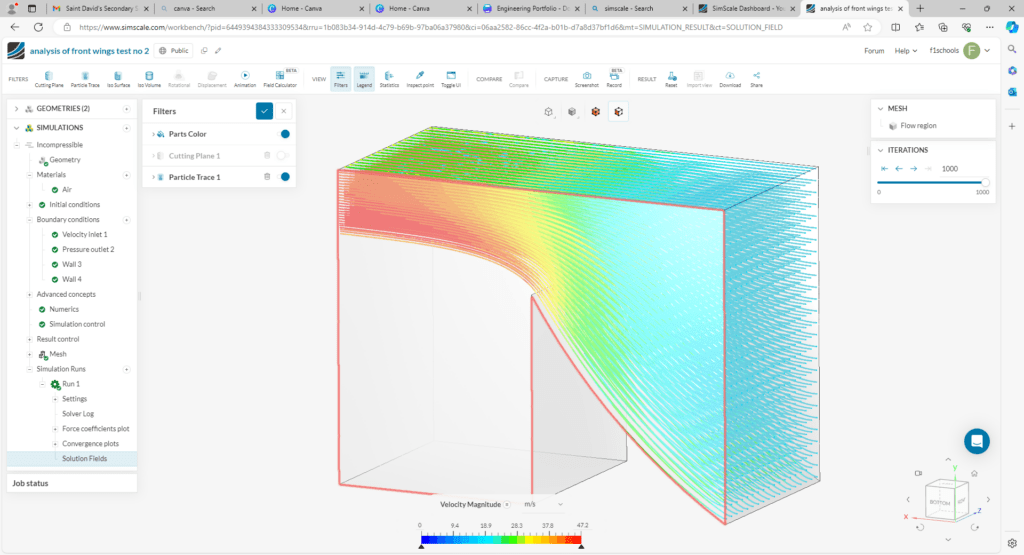

The team utilized SimScale’s incompressible simulation type to analyze and compare the drag coefficients of various design iterations, ensuring the selection of features that would optimize the car’s speed. The process began with importing the desired model as an STL file, created in SolidWorks. After meshing the part and defining key parameters, such as the car’s speed and the viscosity of air, the team generated flow simulations with SimScale, providing valuable insights into the interaction between air and the entire vehicle. Additionally, velocity and drag vectors allowed for precise numerical comparisons between different designs. The team also leveraged the particle trace feature in post-processing to visualize airflow patterns over the car, further refining aerodynamic performance.

With limited prior experience in CFD software, the team had to learn and master its complexities throughout the project—a process greatly facilitated by SimScale’s comprehensive tutorials. Through this learning journey, the team successfully conducted 14 individual simulations, utilizing a total of 44 core hours across various projects. Thanks to SimScale’s efficient platform, average run times remained relatively short, typically ranging between two and four hours.

The simulations provided crucial data, including drag coefficients, pressure diagrams displayed on cutting planes, and particle trace analyses. These insights played a key role in the development of the second-fastest car in Ireland during the 2023/24 season, delivering outstanding performance statistics.