The RFQ/RFP (request for quotation/proposal) is a core, existential process for many hardware engineering organizations. It is where work is won and lost, balance sheets are dictated and company growth potential is determined.

It used to be the case that proposals were gathered (in a leisurely manner) and then a selection made according to the customer’s preferences for quality or cost. But now there is another consideration – bid speed.

Accelerating RFQ/RFP responses: Why the rush?

In many fast-moving and competitive industries – let’s take the automotive industry as an example – the timeframe for an RFQ has shrunk significantly. This is driven by the need to get to market sooner because of a fast moving technology backdrop. In the case of the car industry, this is driven by electrification and battery technology.

Traditional RFQ processes often stretch over several days or even weeks, involving multiple handoffs between engineering, simulation and commercial teams. Each step, from interpreting requirements to running simulations and coordinating design updates, is typically done manually and across disconnected tools.

To get your competitive and de-risked bid over the line first, all that up-front engineering work still needs to happen. Just now it has to be much, much faster.

Beat your competition with agentic AI

Imagine if your business could respond to RFQs in a matter of hours, rather than days or weeks? It would win you more bids, but what would it take?

Interestingly, while few organizations have fully embraced AI in their engineering workflows, the gap isn’t usually due to technical constraints. More often, it’s the result of legacy systems, limited access to data or internal resistance to change. The reality is that effective automation is already achievable by guiding AI with familiar engineering inputs, like geometry, materials, loads and boundary conditions, and allowing it to manage repetitive tasks such as simulation setup, execution and iterative design updates.

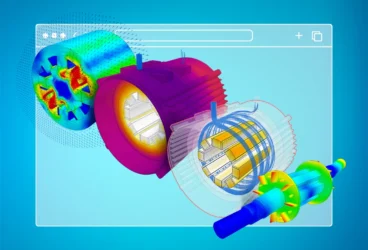

RFQ automation workflow

At a high level, the workflow follows six steps:

- Upload RFQ documents and CAD geometry

- Extract requirements using AI

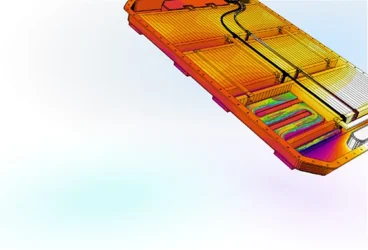

- Automatically prepare and run simulations

- Evaluate results against requirements

- Apply design improvements and re-simulate

- Generate a final report that could be customized for the customer

To see how this works in practice, explore the interactive demo below. It walks through the same RFQ automation workflow described above, showing step by step how an RFQ progresses from document and CAD intake to fully validated results – quickly, autonomously and with engineers in the loop.

Keeping engineers in the loop

Although the RFQ automation workflow operates from start to finish with minimal manual effort, it’s intentionally designed to avoid becoming a black box. One common myth about automation is that it sidelines human judgment. In practice, the most effective systems are those that involve engineers exactly where their expertise has the greatest impact.

This aligns with the growing shift toward human-in-the-loop AI, where intelligent agents take care of repetitive, structured tasks, while engineers retain control. At every stage, engineers can:

- Review extracted requirements

- Track simulation progress

- Assess CAD modifications

- And examine detailed simulation outputs

The workflow remains fully transparent and flexible – it can be paused, adjusted or investigated at any time.

Business impact of RFQ automation

Implementing end-to-end RFQ automation delivers measurable business value that extends well beyond simple productivity improvements. It fundamentally changes how quickly teams can respond to customer requests, how efficiently engineering resources are used and how reliably high-quality proposals are generated.

Key business advantages include:

- Major time savings: RFQ turnaround is cut from days or weeks to just hours, supporting faster decisions and increasing the likelihood of winning new business

- Eliminated engineering bottlenecks: Routine setup and analysis work is handled by the system, allowing engineers to concentrate on strategic design and validation tasks

- Accelerated customer engagement: Shorter response times enable teams to interact earlier and with more confidence during the sales process

- Higher-quality proposals: Consistent, simulation-driven insights and optimized designs help produce more accurate and competitive quotes

Conclusion

End-to-end RFQ automation is transforming the way engineering teams handle customer requests. What used to involve multiple tools, time-consuming handoffs and weeks of manual effort can now be executed through a single, integrated workflow, from RFQ intake and requirement extraction to simulation, design refinement and final report generation. By combining AI-driven intelligence with automated analysis and optimization, teams can respond faster, scale effectively and deliver consistently high-quality, engineering-validated proposals – all without losing visibility or control.

If you’d like to discuss how RFQ automation could fit into your own engineering workflows, feel free to get in touch with our team.