Engineering leaders across the industrial machinery sector are experiencing the urgency to stay competitive in a period when multiple global trends are escalating the pace of innovation. Industry 4.0, sustainability pressures, and AI-driven design are pushing manufacturing capabilities to new heights, allowing faster, more efficient development cycles and breakthrough innovation. Early adopters of simulation-driven design, particularly cloud-native simulation, are already gaining ground, driving quicker market entry, greater design flexibility, and seamless compliance with today’s exacting standards.

For companies still working with conventional methods, the challenge is clear: adapt quickly or risk missing out on a crucial leap forward. It is not about how to innovate anymore; it is about how fast. Cloud-native simulation isn’t just another upgrade; it’s becoming a key differentiator in an industry where speed and adaptability are essential. As more competitors pivot to cloud-native platforms, those who hesitate may soon find themselves playing catch-up in a fast-moving market.

How to Embrace the New Age of Industrial Machinery

As Industry 4.0 brings data-driven insights, automation, and intelligent systems into the industrial machinery space, engineering teams are under increasing pressure to design complex products quickly while managing costs and regulatory compliance. This shift requires more than just adopting new tools; it requires a new way of thinking that integrates digital technologies into every stage of the product lifecycle.

“Digital transformation is no longer optional for machinery sector companies seeking to differentiate themselves and gain an edge over their competition.”

Marie El Hoyek et al., McKinsey’s Industrials & Electronics Practice

With the vast landscape of data, connectivity, analytics, and digital solutions now available, the options can become overwhelming. As a result, many engineering leaders opt to test the waters, taking incremental steps into digitalization. However, a fragmented approach can lead to what’s known as “pilot purgatory,” where companies achieve promising initial results but struggle to scale up their digital efforts due to technical, organizational, or resource limitations.

To avoid this trap, leading manufacturers are embracing a more unified digital strategy, integrating tools like digital twins, predictive maintenance, and real-time data analysis as essential components of their operations. These technologies allow them to stay competitive in a challenging environment where balancing material costs, energy efficiency, and regulatory compliance is essential.

The challenges these companies face are multifaceted. They must balance the rising cost of materials and energy, meet increasingly stringent sustainability requirements, and innovate quickly to deliver reliable, high-performance products. In response, engineering leaders are moving away from traditional design and testing methods and are turning to cloud-native simulation, enabling them to tackle these challenges head-on and reshape their operations.

Navigating Macro Trends with Simulation-Driven Design

Several key trends are shaping industrial machinery manufacturing today, with cloud-native simulation playing a crucial role in enabling companies to adapt quickly:

1. Digitalization and Data-Driven Design

As equipment and production systems become increasingly interconnected, digital twins are revolutionizing design and maintenance. They help optimize performance, reduce development time, and minimize the reliance on physical prototypes by allowing teams to test and refine designs in a digital environment. By enabling real-time monitoring and predictive maintenance, simulation-driven digital twins allow companies to address potential issues proactively and extend equipment lifespans. Such a data-driven approach to design and operations supports faster, more informed decision-making and helps build a robust digital moat in an increasingly competitive market.

2. Sustainability and Energy Efficiency

Sustainability has shifted from a corporate goal to a business necessity. Stricter regulations on carbon emissions, resource use, and energy efficiency now demand that manufacturers assess every phase of a product’s lifecycle—from design to disposal—to reduce waste, improve energy efficiency, and minimize emissions. Customers, too, are seeking machinery that meets high sustainability standards without sacrificing performance. Advanced simulation technologies enable companies to achieve both regulatory compliance and efficiency, streamlining design processes while meeting sustainability goals.

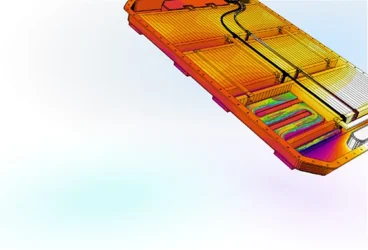

3. Electrification and Hydrogen Integration

As countries work to reduce fossil fuel reliance, demand for electric and hydrogen-powered industrial machinery is surging, especially in heavy machinery, HVAC, and turbomachinery. Electrification and hydrogen combustion offer sustainable alternatives but require manufacturers to rethink design processes to balance energy storage, system integration, and performance. Incorporating simulation early in the design process helps manufacturers optimize equipment to incorporate these new energy sources effectively, balancing energy storage, system integration, and efficiency requirements. Companies leading in electric and hydrogen solutions will be best positioned to meet the power demands of an increasingly decarbonized world.

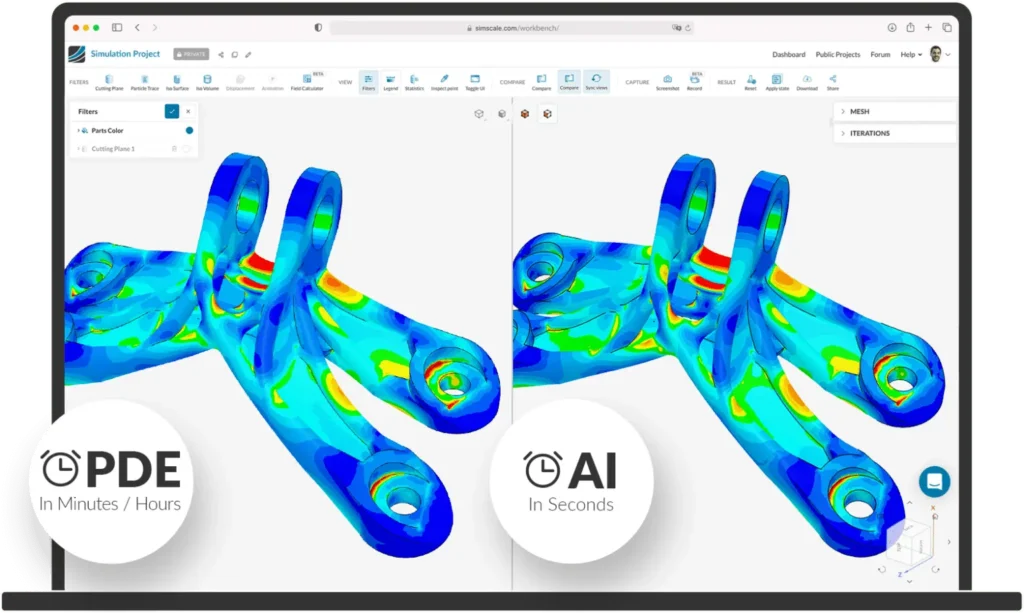

4. AI and Machine Learning Integration

Artificial intelligence and machine learning (AI/ML) are revolutionizing industrial machinery by enabling design optimization and predictive maintenance at an unprecedented scale. Predictive AI allows teams to analyze vast datasets and forecast outcomes more accurately, driving proactive problem-solving and increased efficiency. Generative AI further accelerates design by producing synthetic data to train models, facilitating innovation even when real-world data is limited. The resulting AI simulation capabilities speed up design iterations by optimizing parameters and providing predictive insights. However, successfully integrating AI requires robust data infrastructures and skilled teams to manage these advanced capabilities, making it crucial for companies to balance AI-driven insights with human expertise to stay competitive.

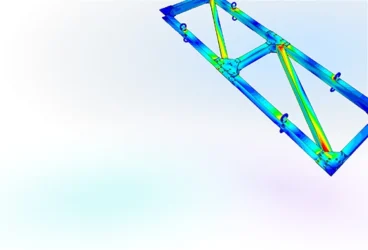

5. Increased Competition and the Need for Speed

Globalization has intensified competition in the industrial machinery sector, forcing companies to shorten design cycles, enhance reliability, and offer tailored, high-performance solutions. As project timelines shrink and customer demands grow, traditional simulation methods often fall short, slowing design iterations and limiting responsiveness. Companies need faster, more agile approaches to stay competitive in this fast-paced environment. Cloud-native simulation accelerates the design process, enabling teams to meet tight deadlines, explore multiple iterations, and bring products to market swiftly, ensuring they remain at the forefront of industry innovation.

Cloud-Native Simulation for Industrial Machinery Manufacturing

For more in-depth insights, our latest eBook explores how cloud-native simulation is transforming industrial machinery manufacturing challenges into opportunities. Download it for free by clicking the button below.

The Transformative Power of Early Simulation Adoption

As these industry trends drive change, companies that adopt early simulation are discovering the competitive edge it offers. Real-world examples demonstrate how cloud-native simulation is a powerful, practical tool that accelerates development cycles, enhances design flexibility, and improves overall performance. By leveraging these capabilities, companies are better equipped to meet today’s complex demands for speed, efficiency, and sustainability.

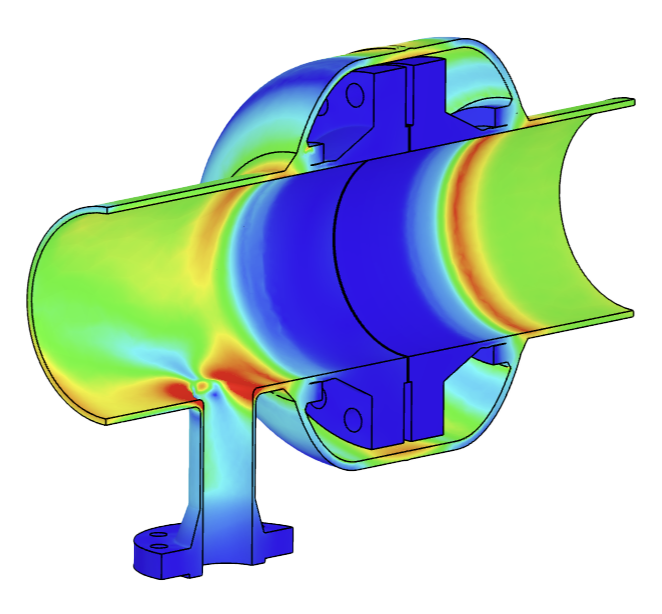

For instance, Hazleton Pumps, a heavy-duty pump manufacturer, faced the challenge of improving pump energy efficiency while meeting rigorous customer demands for performance. By adopting early simulation powered by the cloud, Hazleton reduced development timelines by 99%, completing designs within days rather than months. This accelerated design process enabled Hazleton’s engineers to explore more design iterations, improving product energy efficiency and cutting development time significantly. With early simulation, Hazleton Pumps could deliver advanced, energy-efficient products at a pace their competitors found hard to match.

“SimScale drastically changed our R&D landscape regarding time (99.9% quicker), cost (no HPC and data storage), and simulation accuracy. It allowed us to complete development cycles within days instead of months, which gave us a massive advantage over our competition.”

Benjamin van der Walt, Hazleton Pumps

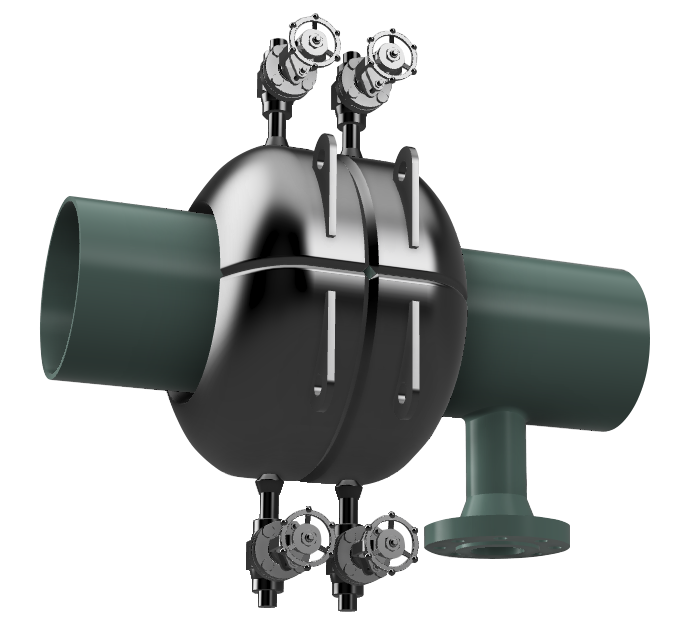

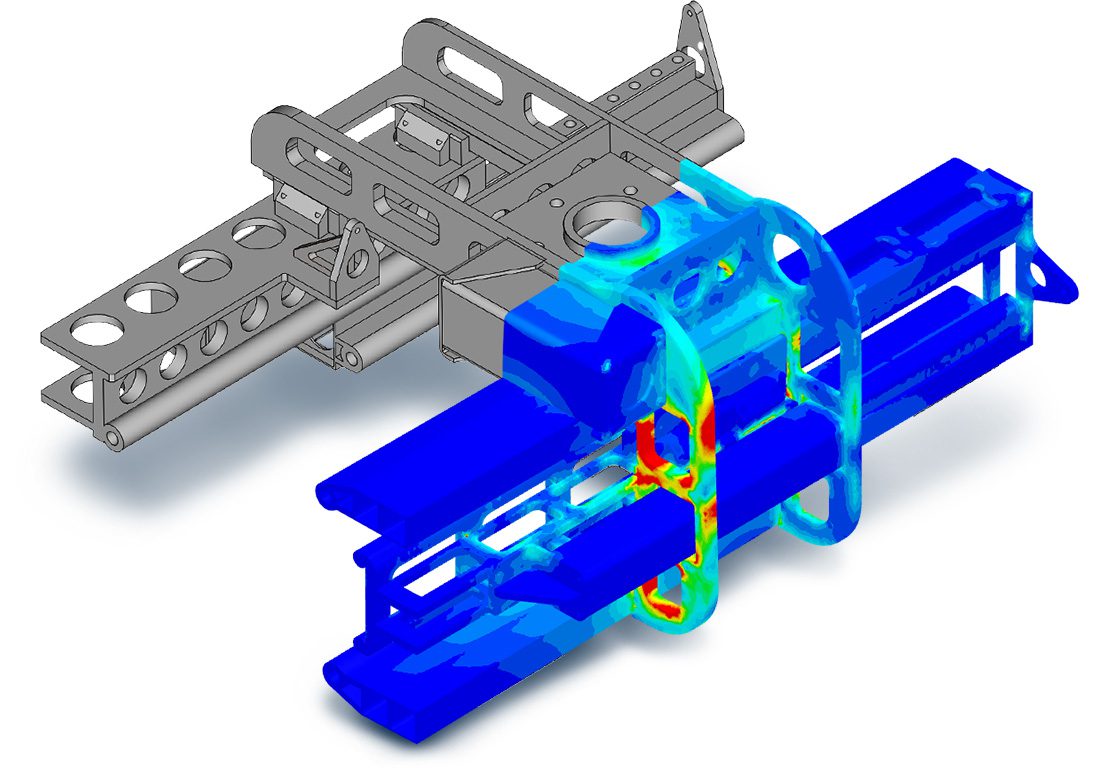

Similarly, Methanex, the world’s largest methanol producer, used cloud-native simulation to solve critical operational challenges in its production pipelines. In one instance, when a leak was detected in a production plant, the Methanex team quickly simulated solutions, optimizing a leak containment component within hours rather than the usual days or weeks. This real-time process optimization saved Methanex millions by preventing costly downtimes and underscored the role of simulation in maintaining operational continuity and efficiency.

These examples emphasize a key point: simulation-driven design enables companies to test and iterate on solutions rapidly, reducing development cycles and meeting performance and sustainability goals faster than ever before.

Gaining a Competitive Edge in the Industrial Machinery Sector

As industrial machinery manufacturing faces mounting pressure for faster innovation and efficiency, cloud-native simulation provides engineering teams with a powerful toolkit to keep pace. Traditional methods, limited by hardware constraints and lengthy lead times, often struggle to meet today’s demands. In contrast, cloud-native platforms offer flexibility, scalability, and collaboration capabilities, enabling companies to design faster, improve efficiency, and address sustainability goals.

For engineering teams looking to enhance productivity, reduce costs, and achieve regulatory compliance, cloud-native simulation offers a suite of tangible benefits:

- Faster Design Cycles: Cloud-native simulation enables engineers to test and iterate designs earlier, reducing the need for physical prototypes and accelerating time-to-market.

- Enhanced Efficiency and Collaboration: With a cloud-based approach, engineering teams across geographies can collaborate more effectively, streamline workflows, and make real-time adjustments based on shared insights.

- Sustainability by Design: Early simulation fosters a more iterative design approach, allowing teams to test for energy efficiency, reduce material waste, and optimize products to meet sustainability targets.

- Scalability and Flexibility: With cloud-native solutions, companies can scale their simulation resources on demand, ensuring they have the computational power to meet evolving design challenges.

- Improved Compliance and Risk Mitigation: Digital twins and predictive simulations allow companies to meet regulatory requirements and minimize risks associated with late-stage design changes or compliance issues.

Cloud-native simulation is becoming essential in a competitive landscape where speed, collaboration, and adaptability are key. By integrating these solutions, companies can stay agile, reduce costs, and bring high-performance, sustainable products to market with confidence.

Future of Industrial Machinery: Adapt or Risk Falling Behind

With the pace of change accelerating across the industrial machinery sector, companies that fail to adapt will risk being left behind. By adopting AI-powered cloud-native simulation, manufacturers can streamline development cycles, cut energy costs, and ensure compliance with stringent performance standards—advantages that early adopters are already leveraging to make headway.

For engineering leaders, SimScale’s cloud-native simulation offers a clear path to meet today’s demands for speed, sustainability, and precision. Embracing these digital tools is more than an incremental step forward; it is a decisive move to drive impactful change, set new industry standards, and secure a competitive edge in a rapidly evolving industry.