Nonlinear structural analysis shouldn’t be a technical niche that bottlenecks your product development. When we first introduced Hexagon’s Marc solver on SimScale in early 2025, it was a milestone for accessible nonlinear FEA. Since then, the integration has matured rapidly — new material models including viscoplasticity, automatic contact detection for large assemblies, and a wave of AI-powered capabilities. In this follow-up webinar, we explored how Marc on SimScale, combined with Engineering AI agents and Physics AI, is making advanced nonlinear simulation accessible to engineers across all industries.

Hosted by Alex Graham (Head of Product Management, SimScale) with Joanna Li-Mayer (Business Development Manager, Hexagon) and Richard Szöke-Schuller (Lead Product Manager, SimScale), here are the top five takeaways.

On-Demand Webinar

Want the full picture? Watch the on-demand webinar on democratizing advanced nonlinear simulation with Marc and AI.

1. The Simulation Bottleneck Is Breaking Down

If you’ve ever waited days for a simulation expert to re-run your updated design, you know the traditional workflow is broken. Designers run simplified linear analyses in their CAD tools, then hand off to specialists for the real nonlinear studies — and what follows is a slow loop of emails, PDFs, and meetings while you wait for each iteration.

SimScale collapses this. On a collaborative, cloud-native platform, both you and your simulation experts work on the same project. Template simulations designed by specialists can be reused and adapted for new designs, while AI agents provide guidance and catch errors. You get faster iterations without sacrificing the depth that nonlinear analysis demands.

2. The Real World Is Nonlinear — And Marc Is Built for It

If you’re relying solely on linear analysis, you’re working with an approximation. The real world doesn’t behave linearly — materials yield, creep, and undergo stress relaxation. Rubber seals stretch and recover. Thermoplastics soften permanently under repeated loading. Parts come into and out of contact, slide, stick, and separate. And loading sequences matter — the same final load can produce entirely different outcomes depending on the path taken to get there.

Marc, the world’s first commercial nonlinear FEA code (since 1971), was purpose-built for these challenges. With over 30 analysis classes, it offers fully coupled structural, thermal, and electromechanical solutions alongside advanced material models — from hyperelastic rubber to viscoplastic materials with damage, creep, and permanent softening. What makes it robust? Automatic contact detection that tracks evolving conditions as parts deform, automatic remeshing when elements distort severely, and intelligent load stepping that adapts as the physics demands. These are exactly the capabilities you need for complex contact scenarios and large-deformation problems.

3. Complex Simulations, Surprisingly Simple Setup

In a live demo, Richard set up a nonlinear rubber bushing simulation from scratch — hyperelastic materials, self-contact with friction — in just minutes, directly in the browser. Import your CAD, let automatic contact detection handle the assembly, assign a Mooney-Rivlin hyperelastic model, define your loads, and run. Everything executes on the cloud with up to 192 cores on a single license.

He also demonstrated sequential loading: applying a 500 N force first, then locking it in place and applying a 45° rotation — configured through simple load steps in the UI. This kind of multi-step scenario is critical for realistic component assessment, and Marc handled the path-dependent behavior seamlessly.

Need to iterate? Duplicate the simulation, tweak the CAD, and re-run — boundary conditions automatically reassociate to the new geometry. Multiple variants run in parallel without touching your local machine. And the built-in Engineering AI agent even caught a unit error (Pascals instead of megapascals) before the simulation launched.

4. AI Agents Automate Your Entire Simulation Workflow

Imagine giving an AI agent a 78-component gearbox assembly and a single instruction. That’s exactly what the webinar demonstrated. A custom “gearbox assessment” agent autonomously identified every component, assigned materials, defined bolt preloads to internal specifications, applied gear loads and fixtures, and launched the simulation — no manual setup required.

A second example went further: a bike frame design workflow where the agent ingested an RFQ document and a CAD file, set up the required load cases, ran them, compared results against specification limits, and recommended design changes when the initial design fell short. You define the agent once with your organization’s best practices, material libraries, and specs — then it handles the rest, consistently, every time.

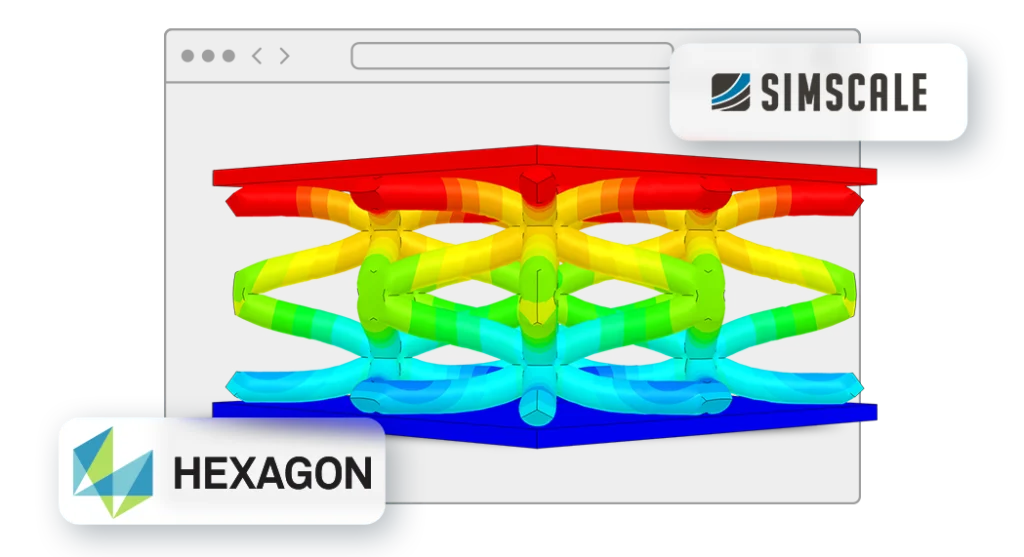

5. Physics AI Unlocks the Nonlinear Design Space

Here’s a challenge you may not have considered: the design space for nonlinear problems grows exponentially. Material parameters, contact friction, geometric imperfections, loading sequences — the permutations multiply fast. And because nonlinear analysis is path-dependent, changing a parameter even slightly doesn’t just shift results — it can change the entire system evolution.

This is where Physics AI complements Marc. By training surrogate models on a relatively small number of high-fidelity Marc simulations, you can predict outcomes across thousands of design variations almost instantly. The surrogate models learn the nonlinear response surfaces, letting you explore the full design space rather than guessing at isolated points. And since everything is integrated on SimScale, you can switch between surrogate predictions and full Marc validations at any point — speed when you need it, fidelity when it matters.

What’s Next: Marc on SimScale Roadmap

The session previewed what’s coming: coupled thermomechanical analysis by end of Q1 2026, temperature-dependent materials in Q2, dynamics analysis in Q3, and adaptive mesh refinement later in the year.

Watch Now

Don’t miss out on the full experience and deeper insights into how SimScale’s latest features can transform your engineering workflow. Watch the complete webinar on-demand to see these tools in action and understand how they can be applied to your specific challenges. Click here to access the webinar recording and start accelerating your design process today!