AI tools have already had a huge impact on the software engineering industry, with headlines like Google’s CEO reporting that 25% of the companies new code is written by AI (and that was some time ago)….

But are we experiencing the same in mechanical engineering?

Our State of Engineering AI survey suggests that only 3% of hardware engineering companies are seeing comparable ‘significant’ gains from adopting AI in their workflows. Why such a small number? One of the most commonly cited reasons was the inflexibility of legacy software.

Luckily, there is a whole raft of new AI tools for mechanical engineers emerging, covering the whole product lifecycle. Let’s dive in.

1. Ideation: Beyond the Blank Page

The conceptual design phase sets the foundation for an entire project. Traditionally, this relies on an engineer’s experience and intuition to sketch out a few potential solutions. AI, specifically through generative design, challenges this paradigm.

Generative Design

Generative design tools use algorithms to explore thousands of potential design solutions based on a set of constraints you define. You input the non-negotiable parameters—functional requirements, material properties, manufacturing methods, and performance criteria—and the AI generates a massive number of high-performing options. Your role shifts from being a generator of a few ideas to a curator of many.

Autodesk Fusion 360

Autodesk’s platform uses cloud-based machine learning to automatically generate and rank design solutions. As an example, check out this case study with General Motors, which used generative design to redesign a seat bracket. The AI-generated result was a single, organic-shaped part that was 40% lighter and 20% stronger than the original component, which had previously consisted of eight separate parts.

nTop

This tool excels in creating highly complex, performance-critical components. For instance, Cobra Aero used nTop to redesign a drone engine cylinder. Instead of traditional cooling fins, the software generated an intricate internal lattice structure. This AI-driven design significantly reduced weight while improving thermal performance—a result that would be nearly impossible to arrive at through traditional design methods.

2. Drafting, Design and Review: The Intelligent Drawing Board

Once a concept is chosen, it must be translated into a detailed CAD model. AI is now being embedded directly into CAD software to serve as an intelligent co-pilot, automating repetitive tasks and streamlining the design process.

AI-Assisted CAD

This category includes AI features that automate common tasks like dimensioning, applying constraints, design reviews and compliance checks. These tools learn from your design habits and company standards to make intelligent suggestions, reducing errors and saving significant time.

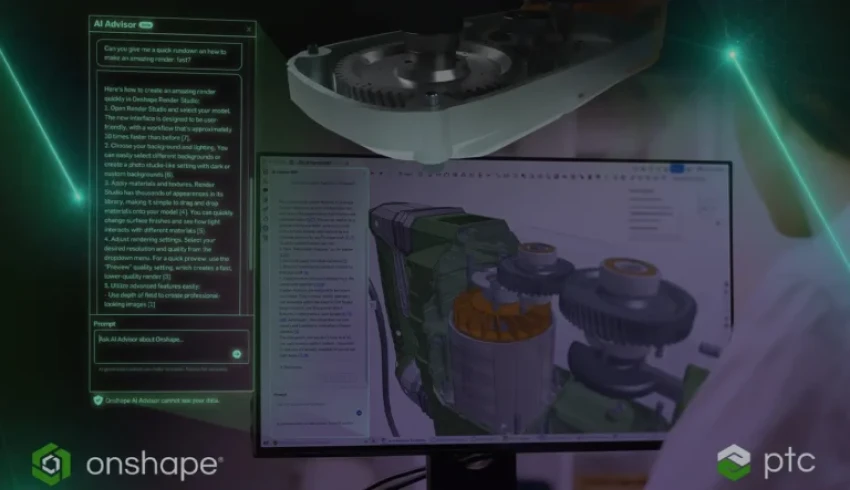

Onshape AI Advisor

This tool acts as an intelligent assistant directly within the cloud-native CAD environment. An engineer can ask natural-language questions (e.g., “How do I create a variable-pitch helix?”). The AI provides step-by-step recommendations, troubleshooting help, and best practices drawn from Onshape’s training materials, effectively accelerating the learning curve and day-to-day workflow. This cloud-native approach is also critical for AI-driven simulation, as it allows parametric CAD models to connect directly to analysis tools like SimScale, enabling the rapid, automated iteration that AI requires.

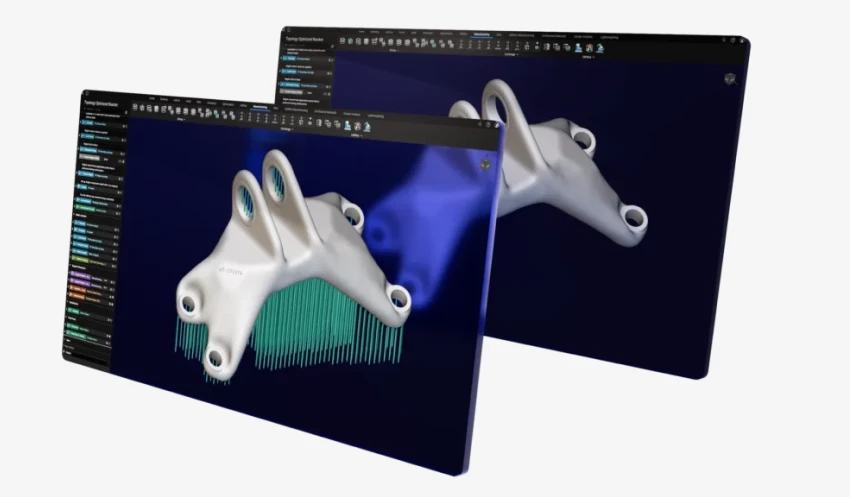

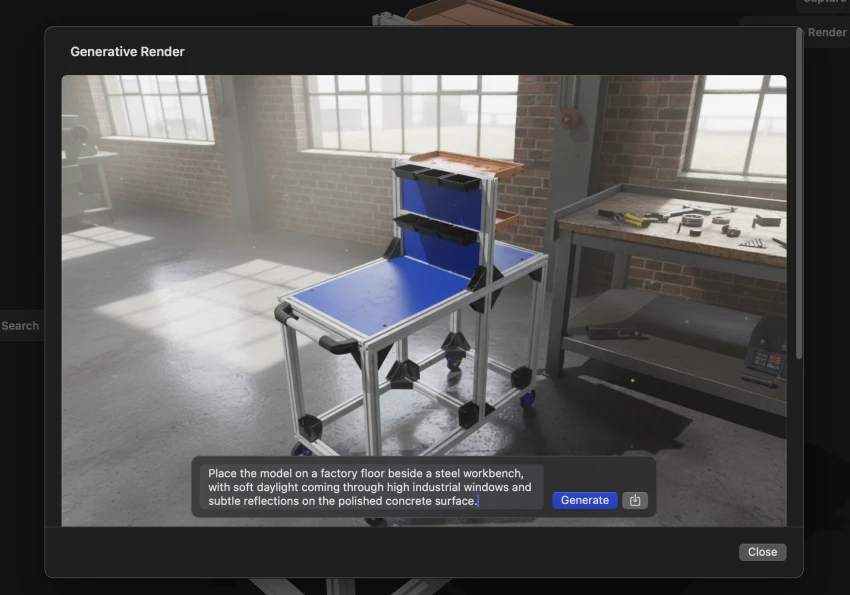

Shapr3D

Shapr3D bypasses the hours typically spent in dedicated rendering software with its embedded AI Visualization. By simply positioning a model and typing a text prompt (e.g., “modern kitchen counter”), engineers can generate context-aware renders in seconds. The tool uses your specific CAD geometry as a guide, allowing for rapid concept validation and “mood boarding.” Features like Variation Intensity let you control the AI’s creative freedom, enabling you to present polished, stakeholder-ready visuals instantly without leaving the design environment.

Intelligent Design Review (ReviewOps)

CoLab Software

While tools like Onshape and Shapr3D streamline CAD creation, CoLab addresses the bottleneck of reviewing it. Traditionally, critical feedback gets lost in “data graveyards” of static screenshots, email threads, and PowerPoint decks. CoLab’s AutoReview utilizes AI to automate the administrative heavy lifting of this process, scanning models against your specific design standards before a human ever looks at them.

This acts as an intelligent “pre-flight check,” automatically flagging routine errors like missing hole callouts or GD&T non-compliance. By filtering out this administrative noise, the AI allows senior engineers to focus their expertise on complex problem-solving rather than checklist verification. This effectively closes the loop between design intent and manufacturing reality, ensuring faster, higher-quality feedback cycles.

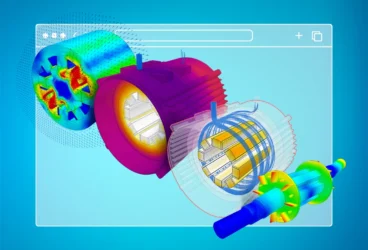

3. Simulation and Optimization: No More Waiting

For many engineering teams, this is the most painful part of the product development lifecycle. Traditional simulation (CAE) is a well-known bottleneck, but it’s actually two problems. The first is simulation cycle time: the hours or days you wait for a complex computation to run. The second, and often bigger, problem is the simulation lead time: the days or weeks spent by specialists manually setting up physics, preparing geometry, and re-meshing every new design variant. This ‘test-and-wait’ workflow means engineers can only analyze a handful of designs. Engineering AI is the solution to this entire bottleneck, tackling both problems at once to achieve one goal: no more waiting.

Engineering AI (Solving the Lead Time Bottleneck)

This category of AI acts as an intelligent co-pilot to automate the complex, multi-step setup process. Unlike a traditional macro or script which follows a rigid list of commands, Engineering AI uses Large Language Models (LLMs) to reason through the physics of your model.

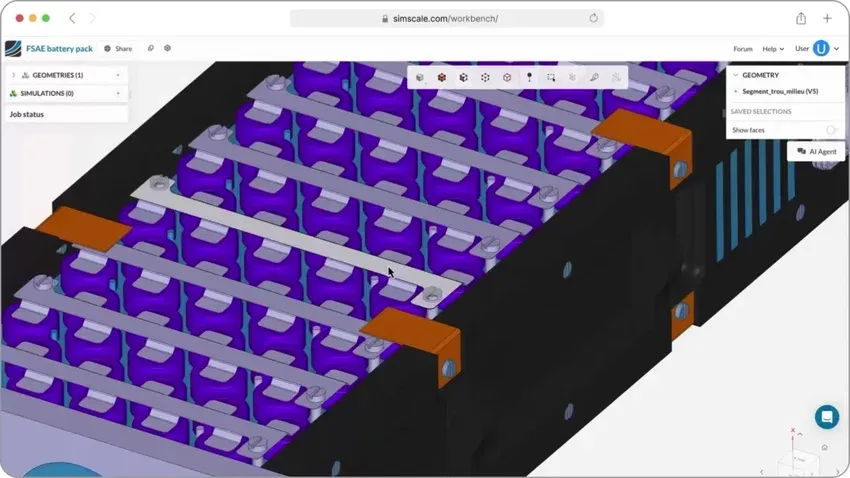

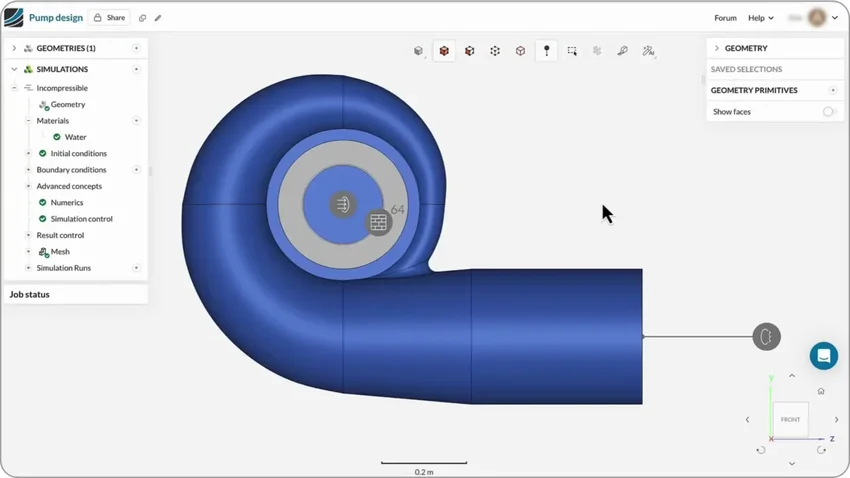

SimScale Engineering AI

SimScale has introduced an agentic AI assistant that resides directly in the simulation platform. It transforms how engineers interact with simulation through three core capabilities:

- Democratization for Novices: Traditionally, simulation required years of specialized training. Engineering AI lowers this barrier by guiding novice users step-by-step. It can diagnose missing inputs, suggest appropriate settings based on the geometry, and flag potential errors before a simulation is run. This turns the platform into a mentor, helping junior engineers get to valid results faster.

- Promoting Best Practices: For larger organizations, consistency is key. Engineering AI can be configured to enforce company-specific “Gold Standard” settings. The agent ensures that every simulation—whether run by an expert in Germany or a novice in the US—adheres to the same quality standards and methodologies, reducing the risk of human error.

- Reasoning and Adapting: Unlike rigid scripts, the agent uses reasoning to navigate deviations. If a geometry changes slightly or a parameter is missing, the agent evaluates the context to adapt its approach rather than failing.

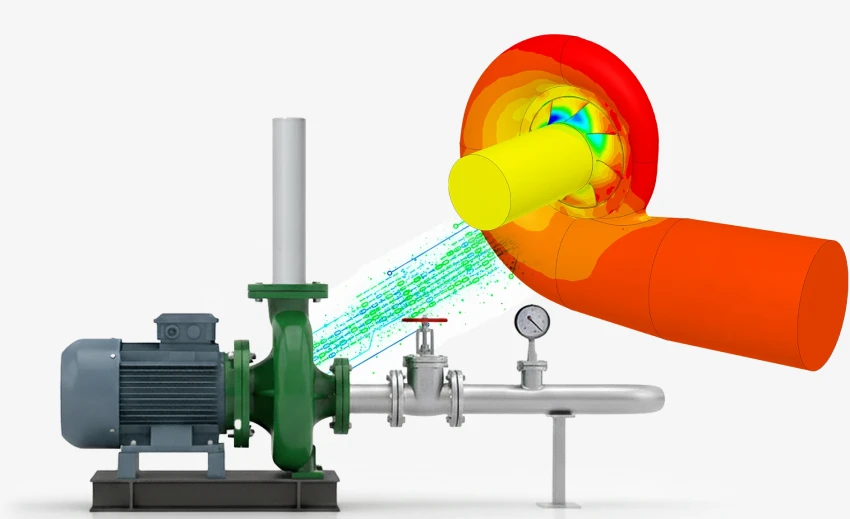

Physics AI (Solving the Computation Bottleneck)

This is the surrogate model. It’s a lightweight, data-driven approximation of a high-fidelity simulation. An AI model learns the complex, non-linear relationships between inputs (geometry, boundary conditions) and outputs (performance, stress, temperature). Once trained, this ‘Physics AI’ model provides near-instant predictions, solving the computation time bottleneck.

SimScale’s Integrated AI Platform

SimScale has integrated this technology directly into its workflow. This approach was highlighted in a real-world case study by Convion, a part of HD Hyundai, who needed to optimize a complex hydrogen ejector pump.

The Challenge: Armin Narimanzadeh, Senior Thermofluids Expert at Convion, faced a multi-objective optimization problem. The design was complex, and using traditional CFD-driven optimization to find the best-performing design would have taken months.

The AI Solution: Using SimScale, Armin’s team first generated a training dataset by running a number of simulations. This data was used to train a reusable Physics AI model within the SimScale platform. The results were transformative. The team now has an AI model that can generate a new, optimized design in under an hour.

This “months to hours” transformation is a perfect example of AI’s power. It was made possible by a fully cloud-native toolchain: a parametric model built in Onshape was connected via an API to SimScale, allowing the AI to automatically test hundreds of variants to find the optimal design. The Engineering AI component automates this workflow, while the Physics AI component provides the instant predictions.

Learn more about the full process by watching the AI Engineering Bootcamp webinar (Session 1) on-demand.

4. Deployment: From Smart Manufacturing to Live Maintenance

AI’s role doesn’t stop when the design is finalized. It extends into the manufacturing process and the operational life of the product (deployment). Increasingly, smart manufacturing systems

Smart Manufacturing

AI is streamlining the path from a 3D digital model to a physical part. CAM software is using AI to automate the complex and error-prone task of CNC programming, which is a major bottleneck due to a shortage of skilled machinists.

Siemens NX CAM

NX CAM uses AI for “Feature-Based Machining”. It automatically analyzes a 3D model and recognizes geometric features like holes, pockets, and slots. It then suggests the most suitable machining operations and sequences, even learning from a programmer’s past choices to improve future suggestions.

Real-time Digital Twins

Once a product is deployed, AI can help you operate it more effectively by building a real-time digital twin. A Physics AI model fed with boundary conditions from a live system can provide crucial insight into function and health, including ‘virtual sensing’ of metrics which might be impossible to directly measure. Machine learning can also be used to predict when it will fail before it happens, based on historical operational data.

Physical AI

Connect live sensor data streams from your operational assets or system-level models directly to Physics AI surrogates via SimScale’s open API. This creates a closed loop where real-world conditions continuously inform and update your digital twin for maximum accuracy.

By combining live data and hardware-in-the-loop (HiL) setups with AI models, you move from reactive maintenance to predictive operations. This allows you to forecast performance degradation and potential failures before they occur, preventing costly downtime and improving asset reliability.

5. The Next Frontier: Multi-Agent Workflows

While individual AI tools are powerful, the future of engineering automation lies in multi-agent systems. Imagine a “digital engineering team” where specialized AI agents collaborate to execute complex, cross-functional tasks without constant human hand-holding.

In a multi-agent workflow, different agents act as specialists—one might be an expert in reading requirements, another in CAD generation, and another in physics simulation. They communicate with each other to complete an objective that spans multiple software platforms.

Synera

Synera, a leading platform for engineering process automation, is pioneering the use of connected AI agents. In the recent AI Engineering Bootcamp (Session 3), Ram Seetharaman (Head of AI at Synera) demonstrated a live multi-agent workflow that orchestrates the entire design-simulate-iterate loop.

In this example, a “Manager Agent” in Synera interprets requirements and delegates tasks. It triggers a “Geometry Agent” to modify a design logic, which then hands off the new geometry to a “Simulation Agent” (powered by SimScale) to validate performance. The results are fed back to the Manager, which decides whether to iterate further or finalize the design.

By chaining these agents together, you eliminate the coordination bottlenecks that often stall projects for days or weeks, allowing for continuous, “always-on” engineering operations.

The Engineer’s Future: AI as an Amplifier

Across all these stages, the theme is the same: AI is an amplifier for engineering expertise. It tackles the repetitive, time-consuming, and data-heavy tasks that slow down innovation. This allows you, the engineer, to focus on what you do best: problem-solving, creativity, and making the critical decisions that lead to breakthrough products. The companies and engineers who embrace these tools today will be the ones shaping the future of the industry.