Computer simulation technology has developed in close relation with both the computer industry and engineering processes. Associated with the process manufacturing industries, simulation has been customarily used as a tool to increase the production capacity.

In the early stages, computer simulation was not very accessible; a lengthy process, the ambiguity of resulting models, and a large number of required specialists resulted in prohibitively expensive associated costs. Until the wide-scale adoption of computing algorithms in 1970’s, industrial engineers learn about computer simulation models in schools but rarely apply them.

Development in computing, modern programming language, visualization tools, and graphics have had a huge impact on the evolution of simulation technology.

Main History Milestones

1943 – ENIAC (Electronic Numerical Integrator and Computer) was the first digital machinery construction and started in secret at the Moore School of Electrical Engineering, University of Pennsylvania. Its main goal was ballistic trajectory calculation [1];

1945 – Jon Von Neumann developed the “merge sort” algorithm, which was integrated with one of the first computer simulation programs running on the DVAC (Electronic Discrete Variable Automatic Computer) [2];

1952 – John McLeod, a pioneer in modern simulation, founded the first Simulation Council, known today as Society for Computer Simulation (SCS) [3];

1961 – IBM presented the “Gordon Simulator” to Norden (systems design company), which comprised a tool used to design a system to distribute weather information to general aviation [4];

1964 – CACI Products Company released SIMSCRIPT, a powerful free-form simulation language designed to simplify writing programs for simulation models, used especially in inventory simulations [3];

1967 – Norwegian Computer Center developed the language Simula67 [3];

1967 – Continuous System Simulation Language (CSSL) was developed by the Society for Computer Simulation [3];

1979 – Alan Pritsker developed the first version of SLAM, a FORTRAN based computer simulation language;

1998 – Micro Saint v2.0 for Windows 95 provided automatic data collection, optimization, and a new Windows interface, without any programming language requirement;

2008 – NASA released the Standard for Development of Models and Simulations;

2012 – Barna Szabo and Ricardo Actis introduced simulation governance as a technical requirement for mechanical design [5];

2013 – SimScale officially released the world’s first and only 100% web-based engineering simulation platform [6];

What is Computer Simulation Technology Offering Today?

Today’s modern versions of simulation technology regularly provide a set of features:

- A uniquely structured environment that facilitates models with rapid geometry setup function

- Automatically details generation, windows interfaces, and pop-up menus

- Easy and quick to use, with lower risks of errors

- Built-in material handling patterns and templates

- Product design verified and tested faster, offering 3D views alternatives

- 3D graphics automatically created as the user enters data

- Simulations results can be instantly viewed in 3D animation [3]

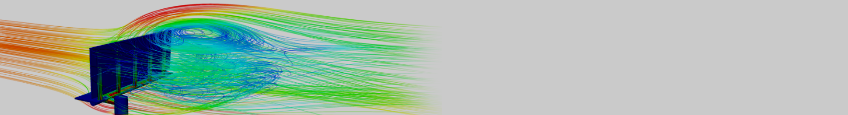

Real-time simulation technology is used today in various industrial applications in the fields of manufacturing, energy and power systems, industrial equipment, valves, pumps, automotive, and airplane engines. The key challenges in the industrial simulation are digital model integration, reducing time to market, computational processing power, energy efficiency, and the associated cost reduction.

Real-time simulation technology is used today in various industrial applications in the fields of manufacturing, energy and power systems, industrial equipment, valves, pumps, automotive, and airplane engines. The key challenges in the industrial simulation are digital model integration, reducing time to market, computational processing power, energy efficiency, and the associated cost reduction.

The first step in the simplification of the simulation process was the separation from traditionally designed applications, achieved by the universal recognition of major project files with standard extensions. This offered total independence between product design and the simulation process.

The migration of computer simulation software into the Cloud has made a massive impact on product cost reduction, quality improvement, and market-ready effectiveness. All major CAE providers have started offering alternative services to the traditional on-premises simulation software, but not covering all benefits Cloud has to offer.

What is Next in Engineering Simulation?

Some industry analysis trends emerged at the last edition of the NAFEMS World Congress—(International Association for the Engineering Modelling, Analysis, and Simulation Community established in 1983)[6].

- Design-centric workflow – already adopted in digital industry models

- Ease of use and/or usability – applications should be friendly, for large numbers of users

- Analysis and simulation of CAD – as part of modern digital processes

- The impact of the Web, Cloud, and mobile devices – opening access and communication facilities

- Capturing and reuse of knowledge – by embedding digital data science models

- Systems approach to combining heterogeneous models – multiphysics simulations

- Speed and model fidelity – improved by Cloud infinite computational power

- Unattractive technical issues – limited by opening access to knowledge

- Changes to licensing models – due to essential differences offered by Cloud subscription Software as a Service (SaaS) models

- Nano simulations – finite element analysis and simulation at the nanoscale opens up a vast applicability in the field of biological engineering

These trends are linked to a major initiative to expand the use and benefit of engineering simulation to larger user categories, “The goal is to gain better advantage and growth of CAE software given the business drivers that push the need for more innovation and creative competitiveness”, says Joe Walsh, CEO of IntrinSIM [6].

Experts appreciate that the simulation democratization process has currently three obstacles: software costs, hardware expenses, and expertise training. The Cloud models offer a solution for first two of these stumbling blocks, opening the doors to vendors which offer freemium versions of simulation analysis on a pay-by-use model. “We need to reduce the level of expertise required to do simulation,” says Walsh in an interview for Engineering.com [6]. “This is referred to as design-centric workflow rather than simulation-centric. This way simulation is used to derive and drive design decisions as opposed to just using it to do an analysis.”

“The Next” is Here, with Reliable Alternatives

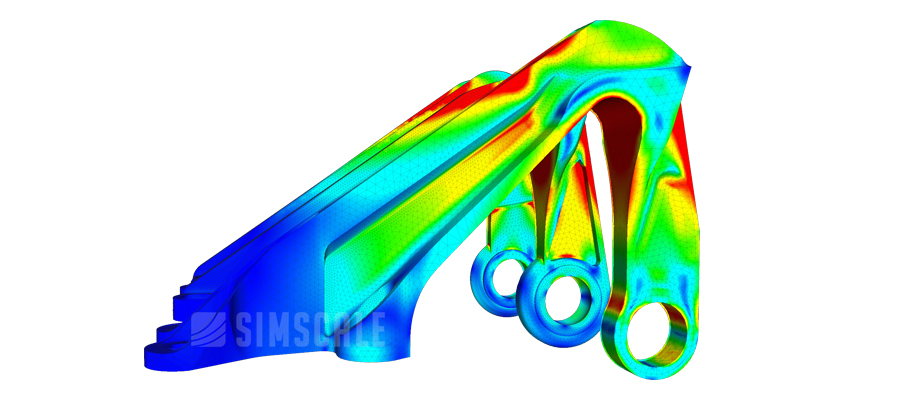

With its web-based engineering simulation platform, SimScale offers real answers to all three major obstacles in the computer-aided engineering (CAE) democratization process. SimScale has created a completely new approach to how CAE technology can be used, by making it accessible, cost-efficient, and easy-to-learn and use.

Accessibility – any user has access to necessary powerful computer simulation technology running in a simple web browser, without any supplementary hardware, software or maintenance resources;

Cost-efficiency – using SimScale, users pay only for what they use, achieving the best cost/ performance in the engineering process;

Breaking knowledge barriers – any SimScale operation is easy to learn and use. “With SimScale, we have this unique situation that for the first time in the history of simulation software, the functionality itself, the people, the content, and the know-how are all brought together in one place, on one platform which can ultimately help everybody to learn simulation faster and apply it more effectively,” said David Heiny, Managing Director and Co-Founder SimScale in an interview for DEVELOP3D LIVE magazine.

SimScale’s CEO David Heiny tests the capabilities of the platform to solve a real-life engineering problem. Fill in the form and watch this free webinar to learn more!

References

- Weik, M. (1961) The ENIAC Story, American Ordnance Association

- Knuth, D. (1987) Von Neumanns First Computer Program, MIT Press

- Raczynski, S. (2014) Modeling and Simulation: The Computer Science of Illusion, John Wiley and Sons, 2014

- Simulation: 20th Century Issue, Society of Computer Simulation

- Szabó, B., Actis, R. (2011) Simulation governance: New technical requirements for software tools in computational solid mechanics. International Workshop on Verification and Validation in Computational Science University of Notre Dame

- Desktop Engineering (2013) SimScale Online Platform for Simulation

- Wasserman S. (2015) CAE Industry Experts Predict Future of Simulation”, Engineering.com