I tried it with the setup you made but it stops and won’t go beyond 38 percent. What can be done to fix that.

I am working on a project for school that involves replicating the human heart. I came up with a composite that would hopefully replicate it, and all I want to test is the strength of the composite. I have experienced issues such as walls going through each other, it expanding like a balloon, or the simulation flat out fails. I have tried linear, non-linear, and hyperelastic models. I have posted this question before and have gotten responses, and although they have helped somewhat, they haven’t gotten to the root of my problem. I am not skilled in Simscale by any means; I am practically clueless, and all I want to test is whether my material is strong enough. I will provide links to my project and previous forum posts to help fill in any blanks. It would be great to have another point of view to help find a solution.

Thanks.

Here is the link to my previous forum discussion that will keep you up to date

Here is the link to my project

Hi,

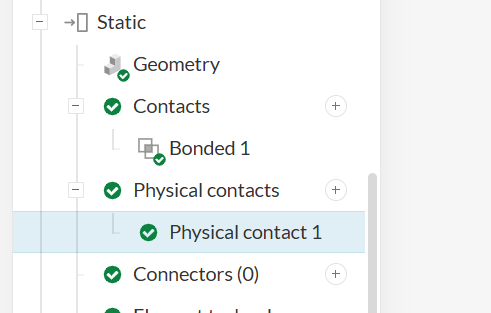

Commenting exclusively on the “walls going through each other” comment: a pair of faces will only account for one another if they are part of a contact (either a linear contact such as bonded and sliding, or a physical contact if you have nonlinear studies).

If two faces that are not defined as master/slave assignments of a contact happen to touch in the simulation, they will ignore each other. The solution for this is fairly simple: you just have to create the appropriate missing contacts.

Now, whether or not the amount of deformation that you are seeing is expected, that depends on material properties, loads, and how you are constraining the parts of the assembly.

Cheers

Thank you for the response,

So what should I set for it because I can really change the values for the material and when I do linear elastic the walls go through each other. Also when I set the pressure it is way higher than I want it to be and I don’t know how to make it lower since I don’t understand why it is so high in the first place.

Cheers

Sending this in case you didn’t see my response

I am working on a project for school that involves replicating the human heart. I came up with a composite that would hopefully replicate it, and all I want to test is the strength of the composite. I have experienced issues such as walls going through each other, it expanding like a balloon, or the simulation flat out fails. I have tried linear, non-linear, and hyperelastic models. I have posted this question before and have gotten responses, and although they have helped somewhat, they haven’t gotten to the root of my problem. I am not skilled in Simscale by any means; I am practically clueless, and all I want to test is whether my material is strong enough. I will provide links to my project and previous forum posts to help fill in any blanks. It would be great to have another point of view to help find a solution.

Thanks.

Hi @mkilgore, in my view Ricardo’s comments are spot on - have you tried changing the material properties? How did you retrieve the Neo-hooke properties of the heat valve?

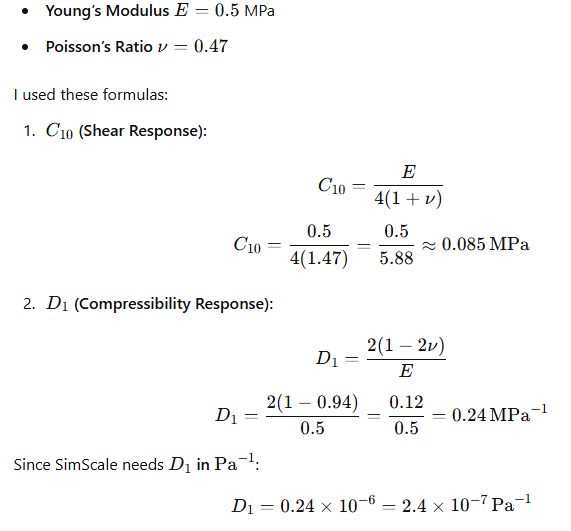

Hi, @igaviano. thank you for the response. I will provide a screenshot of my explanation since I can’t exactly type down the formulas here. I can’t really change the properties of my material because that would make it another material. If you are asking if I have tried other types, like linear and non-linear, I have. Also, if you need any other information to get a clearer picture and more easily find my solution, just let me know, and I would be more than glad to provide it.

After sending this I realized I used an Young’s Modules of 0.5 when it should have been 0.96 I will test and see if that works and let you know.

Hi @igaviano. I have tried it with the proper values, and issues are still appearing. The simulation completes, but it balloons and walls go through each other.

Thank you both for the responses, sorry I have not responded in a timely matter, I had been studying for the ACT’s. I had readjusted the values to the correct this time. Thank you for the recommendation to try the slave and master values, and I believe that could help with the issue, btu which should I select for each c because I attempted doing that int the past but the simulation failed. Is there anything else I can do. Lastly, I know this is not your job by any means but could you possibly help me set it up or provide me detailed instructions on how to do it because this is for a grade in my class and I either do this and provide the results or I just say they are inconclusive. Still overall I have really appreciated the help and time you have given me.

Thank you.