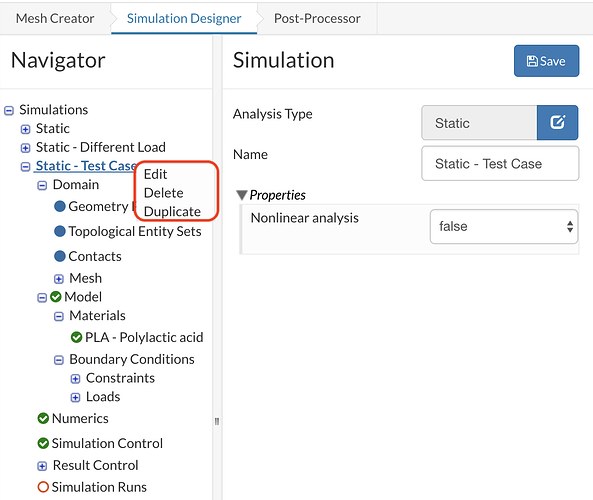

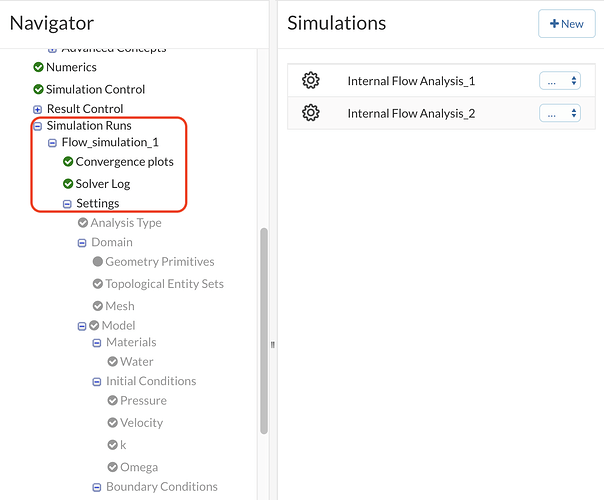

Partly. Had I done that, it would allow me to back track to an earlier (working) simulation,

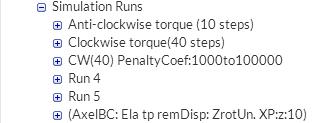

But it wouldn’t inform me what I had changed between the two, unless I (again) try and capture each change in the names I assign tot he simulation.

Basically, I got this whole host of computing power available to me – my machine, and yours, – and I’m reduced to trying to remember what I changed and writing things on scraps of paper.

It also means that I am reduced to making a single change for every run I try, for fear that if it start crashing, then I won’t know which change crashed it. Even trivial changes – like increasing the number of cores from 4 to 16, are enough to cause a simulation that completes, to start failing with one th your catch-all – something’s wrong errors.

My latest simulation, with just 2 parts and one motion, is just as fragile as my earlier more complicated attempts. And yet, so far, it hasn’t tested anything.

That is to say, the whole purpose is to see the effects on the TA, of the torque being transmitted from the axle; but so far, no force has been transmitted. The entire TA remains blue in the results regardless of whether you inspect displacements, or stress or strain.

That may be because I’ve reduced the penalty coefficient of the physical contact BC so low (as advised by the help for one of the other error messages in an earlier failure) that the TA is effectively made of plasticine; and just deforms out of the way locally without transmitting any force.

But if I raise the penalty coefficient above 1e6 (it should be nearer 1e16?), the simulation again fails with a catch-all error that the only apparent fix is to change the simulation such that it doesn’t reflect reality.