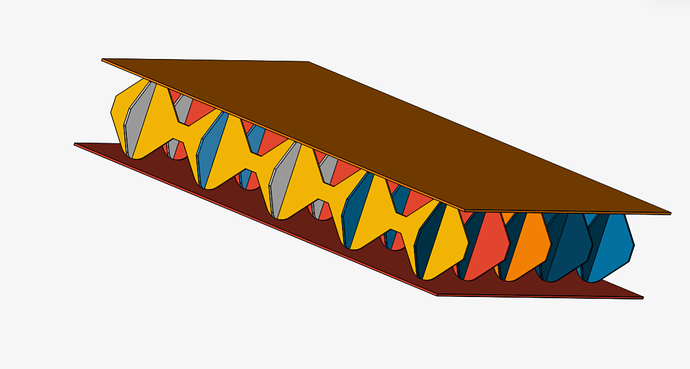

I am trying to get the reaction force from a fixed support in a displacement controlled compression test on a sandwich structure. There are 4 parts- Skin, Core top, core bottom and bottom skin. The core is interlocking.

Physical contacts have been defined between- top skin-core , Top core- bottom core and bottom core-skin.

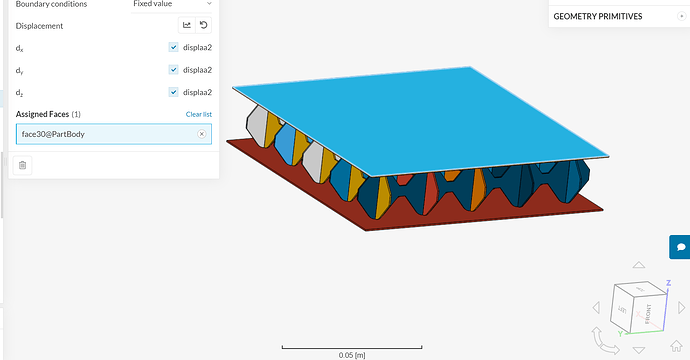

The displacement is applied as a fixed value to the top skin. Applied as a table and with intention of giving displacement rate as 1mm/min ( still assuming that the rate will not have affect as static analysis).

This is the table for displacement. Negative displacement in Z direction is assigned to get compression.

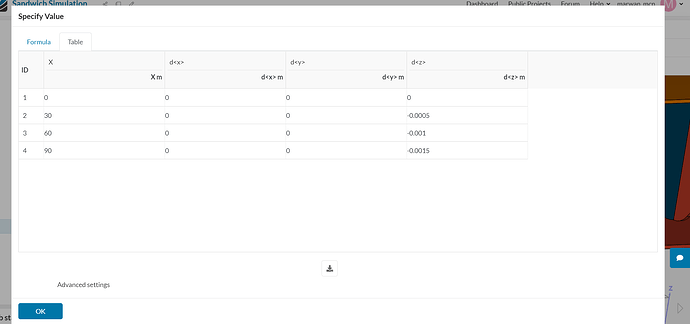

Fixed support is assigned at bottom face of bottom skin. This is the support where reaction force is probed for.

Elastic supports have been added to the core surface which is close to the contact area to the skin. This ensures no rigid body motion from slipping.

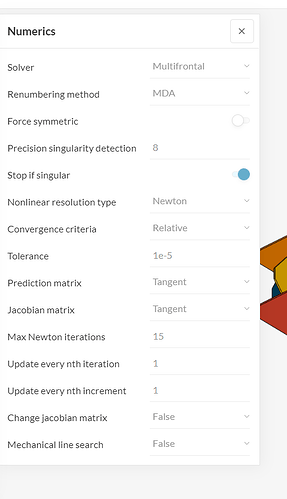

The solver i have opted for is the PETSC solver.

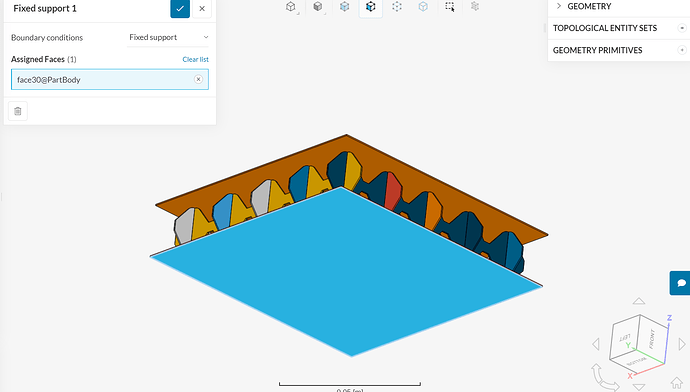

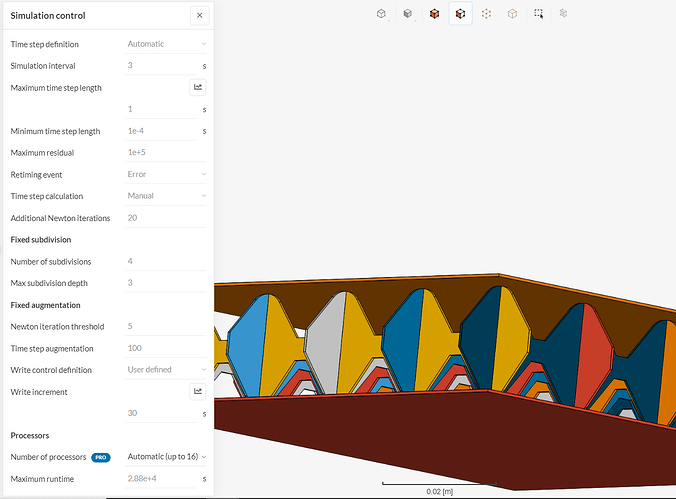

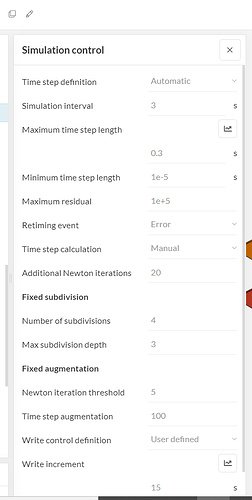

The simulation controls have been changed to -

I have have changed the simulation interval to 3 seconds as i assumed it would break each of my displacement periods of 30 secs into 3 secs and thereby get 10 steps. This was the only understanding of simulation i could get from reading the documentation and help pop up.

The maximum time step length was also increased as my understanding of the parameter is that if increased it should reduce computation time.

Also i have observed that the simulation fails after longer when i use the initial time steps setting for write control definition instead of using the user defined option.

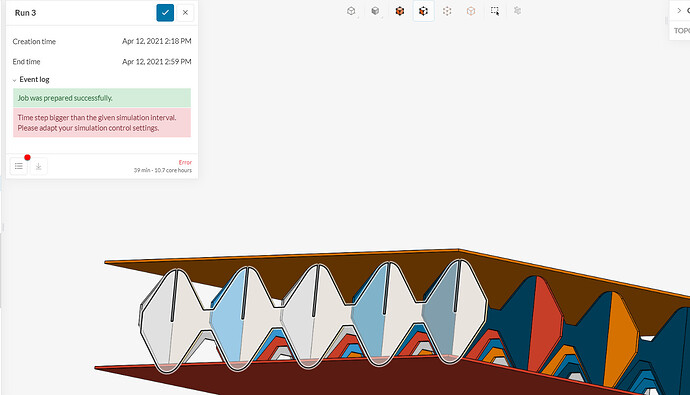

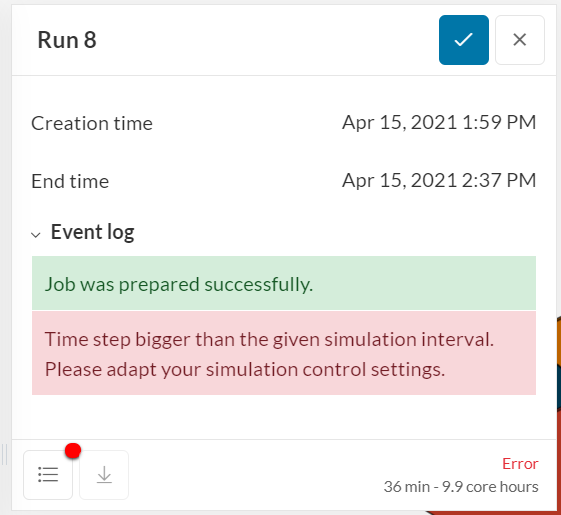

“Time step bigger than the given simulation interval. Please adapt your simulation control settings.”

The above error was in Run 3 for the “disp_change” analysis in my_project

In run 5 i tried using the Multifrontal solver and reduced the max time step length to 0.05s and still got the same error.

Could it be explained what each of the simulation control settings mean and how they affect the results and how can i get through this error ?

Thank you