Hey,

I am trying to run a cht analysis for a cold plate and I am not able to get end result for the simulation the temperature keeps rising up can anyone help me with setting up the boundary condition’s.

I will look at your project and will come with a suitable solution as soon as possible.

Cheers,

Ani

@ssribhashyam the problem that I see is you have not set up an interface between the steel plate and the water. I would suggest you watch the following video as it shows how to setup those interfaces. Conjugate Heat Transfer with SimScale

@ssribhashyam, the problem is you have not set up any contact regions so far. First you need to set up a contact face set for each one of the faces on the tube and for each on the block. This would be easier if you set up your entire tube system to be a single face using a loft operation. I know how to do that in NX/Solid Edge but have never tried in OnShape. Does that make sense?

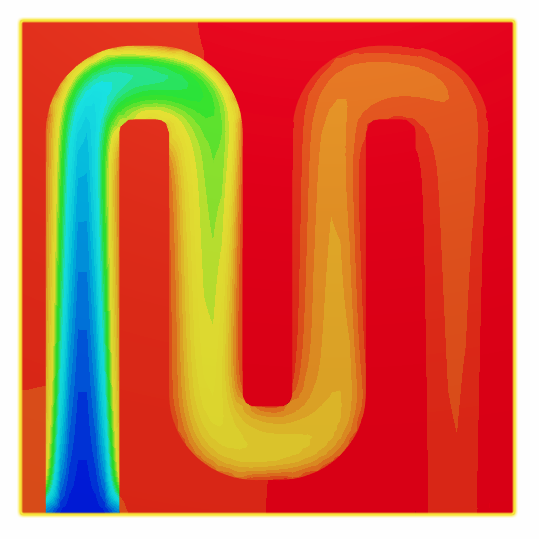

It looks like SimScale assumes anything that doesn’t have a boundary condition is automatically set to a heat transfer boundary. Here is a quick and dirty solution that I got from your file.

It looks like the fluid goes from about 300K to about 600K while the plate ranges from 570K to 600K. Is that about what you were expecting?

@LWhitson2 i have run it on ansys the maximum temp on it was at 352k so im hoping to get the same results here

Are you confident in your results from ANSYS? Have you done a back of the envelope energy balance to see what the theoretical solution should be? Are all the units and physical properties the same between the simulations? Once you can confidently answer these questions then we can move forward with seeing if there is an issue in this solver.

@LWhitson2 Can u run the model with v=0.1m/s2 q=81250w/m2

And do i need to use any wall condition between the fluid and solid.?

If you copy my case above you should be able to run any case you want. Poke around in there a bit and let me know if you have any questions about what I did or how I did it.

As u can see from the link above i am getting temperature at 2000k

@ssribhashyam let’s work through the problem starting with first principles. In essence you have water going in one side of the plate with a given velocity (V_w) and it is being heated by a heat flux on the plate (\dot{q}''_p). At steady state the water will take all the heat from the plate and increase the temperature overall. Let’s work that out:

Water Heat Balance:

\dot{Q}_w = \rho_w c_{p,w} (T_e - T_0) V_w A_w

Plate Balance:

\dot{Q}_p = \dot{q}_p'' A_p

If we combine these expressions we get the following equation for the temperature change of the water:

\rho_w c_{p,w} (T_e - T_0) V_w A_w = \dot{q}_p'' A_p

Now we solve this equation for the temperature change of the water:

\triangle T_w = \frac{\dot{q}_p'' A_p}{\rho_w c_{p,w} V_w A_w}

I know the following values based on your run setup:

\dot{q}''_p = 81.250*10^3\,\text{W/m}^2 \qquad V_w = 0.1 \text{m/s}

c_{p,w} = 4.180*10^3\,\text{J/(kg K)} \qquad \rho_w = 997\,\text{kg/m}^3

\triangle{T}_w = \frac{0.195 A_p}{A_w}

Your plate looks about 0.04\,\text{m} wide and the openings are about 0.006\,\text{m} in diameter. That gives me a final \triangle{T} \approx 11.03\,\text{K}. Now that we have a rough value for what the temperature change should be, let’s look at why your temperature change is so large.

Looking at your case setup, you have specified Water as your working fluid; however, you have the Equation of State set as Perfect Gas instead of Constant Density. You also have your upper wall set to Turbulent Heat Flux instead of External Wall Heat Flux with a Fixed Heat Flux. I would try fixing those things first and see what happens.

Thank you for taking your time and helping me ill make the changes and get back to you with the results

Hey

I have made the changes and i am getting similar results

@ssribhashyam, I have tried a few things myself and the numbers aren’t working out for me either. Let’s get the @cfd_squad to take a look and see if they can find the issue. Thanks for being patient with us while we see what the problem is. Probably something small we are both missing.

Here is a link to my case where I have physically linked all the relevant patches manually as well. Still the same answer. SimScale

LOL, that is a new one, who did that?

But sorry, I’m just watching with interest ![]()