Hello all,

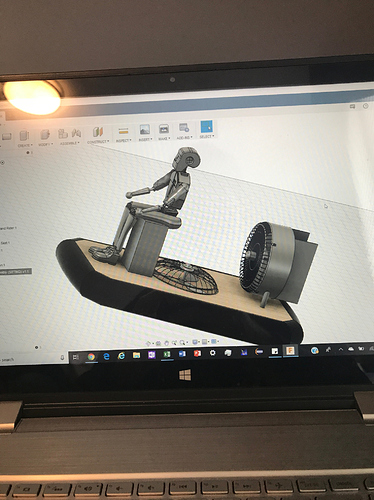

I am trying to do a simulation that simulates the fluid flow around a dual-fan hovercraft, specifically the drag coefficient (and lift force probably). I recently tried to mesh the project, but ran out of memory on 32 cores. I could of course move up to more cores, but I don’t think I am being efficient enough with my symmetry choices. I know that without the fans, I would cut the craft in half long-ways and only use that half for the simulation. However, with a fan blowing air downwards as well as one blowing air backwards, how would I account for that with symmetry? I couldn’t just cut it in half, because the flow isn’t mirrored across the symmetry plane when there is a fan spinning in one direction. Would cyclic symmetry work? If so, would that override the simple symmetry that would cut the whole thing in half longways? I haven’t seen an example of a project that used cyclic symmetry for a rotating propeller. If that isn’t an option, then I guess I could get rid of the propellers, cut the whole thing in half, then use a momentum source instead of a rotating zone. That should give me the same drag coefficient and lift, just without the exact streamlines of flow around the fan regions. I should also try to simplify the rider in the model, as it has 5000 faces.

So - in summary:

- Would cyclic symmetry work with a rotating propeller?

- If so, could you also include only a tiny section of the fan grill?

- If so, would it still work with a cut-in-half length-wise symmetry configuration?

- If so, how would you go about setting up the new geometry and mesh so that all the symmetries produced the proper image?

- If not, would momentum sources be a better option?

Here’s a picture of the CAD model I’m talking about: