Hi @grosua

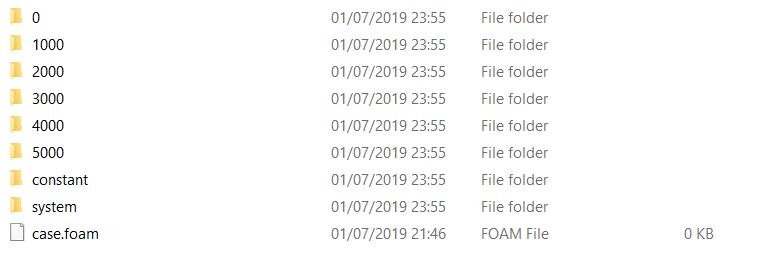

I am glad that helps you further along the road. If running low, don’t hesitate to ask me to run some of your sim, or we could ask Jousef. To download you simply go into the project I shared with you, in Run 2 there is a download button. It says 0 seconds but the results should be there, what you will obtain after downloading is this folder structure:

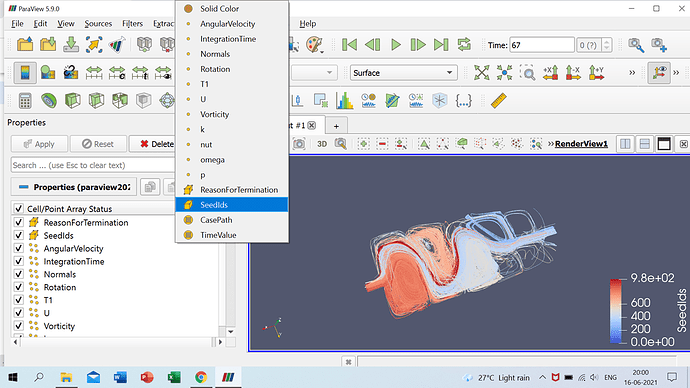

After starting paraview, you click open and select the .foam file, after opening the file, it is not loaded yet and you have to click on apply:

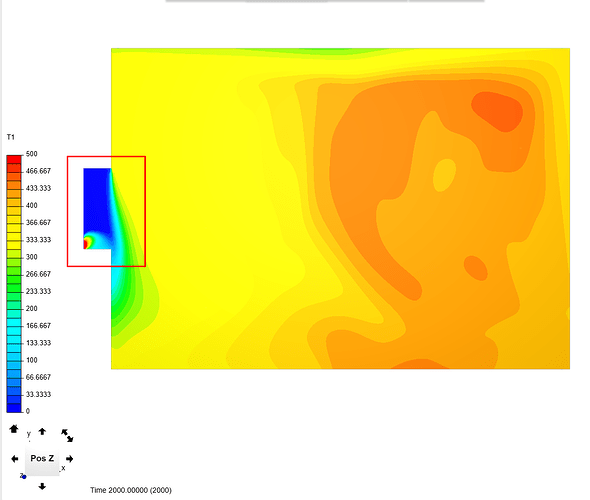

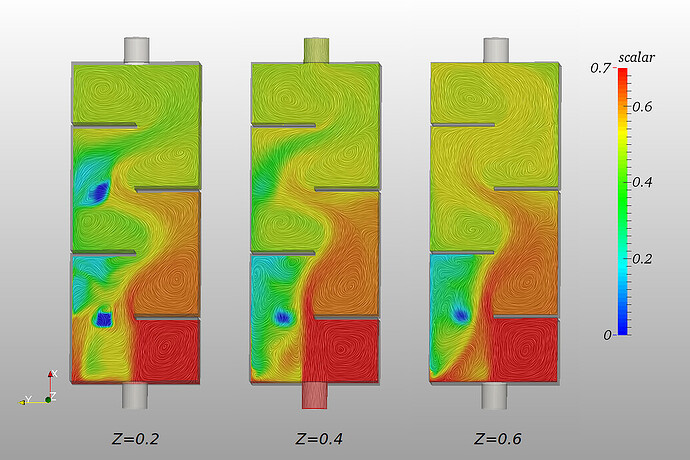

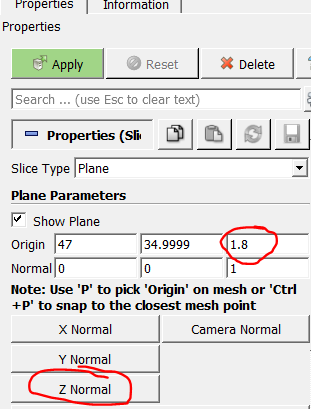

To get a cut plane, click here and adjust the normal vector and center location to your wishes:

Don’t forget to click apply.

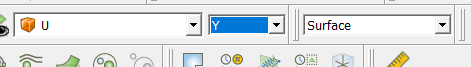

Now in the top you can pick a variable and its component if it has components:

With this method you can get cutting plane results.

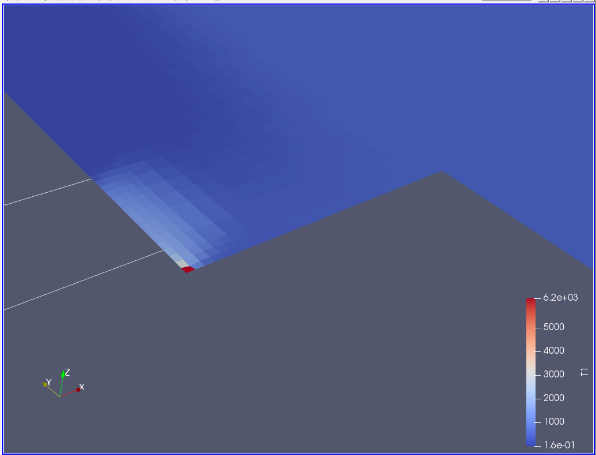

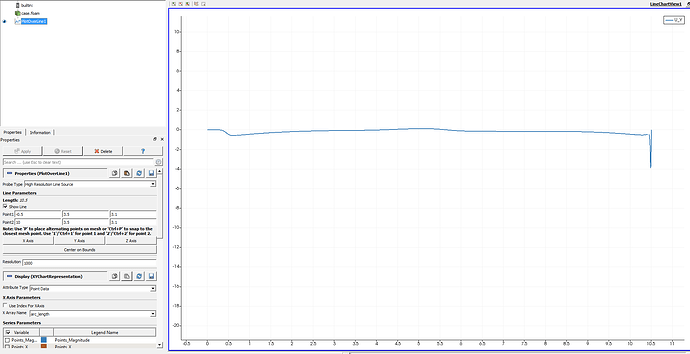

To get a line plot, you need to proceed differently. I deleted the slice that was just created and then clicked this button

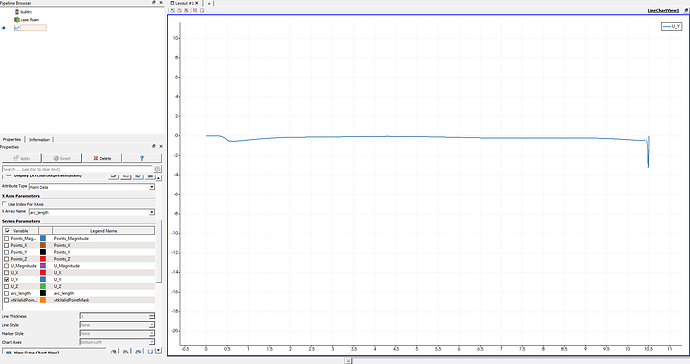

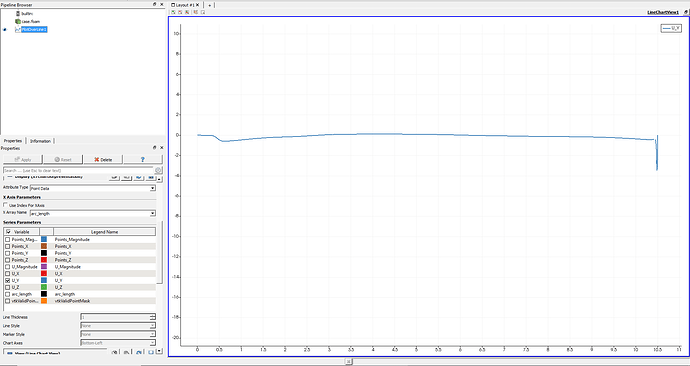

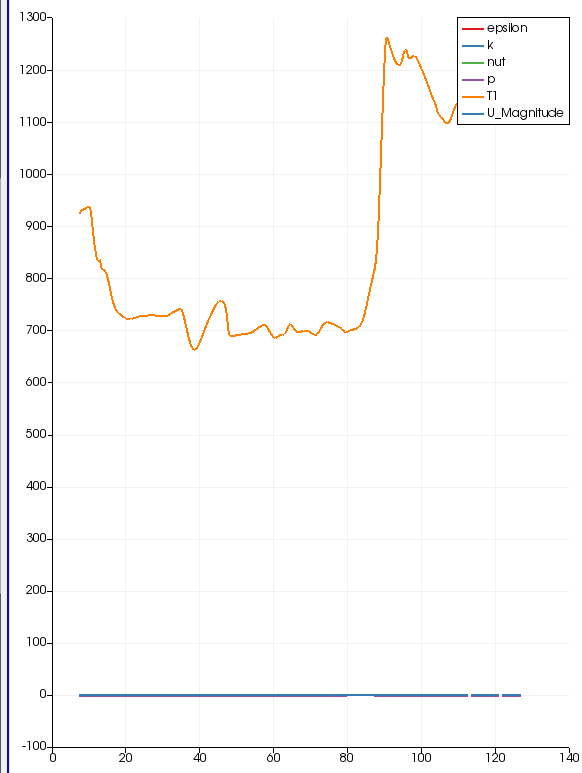

By default a line which goes accross your whole domain will be created, but you can change the start and end points to your own wishes. Every time when you perform an operation in paraview, do not forget to click apply. After applying the plot line, you will get something like this

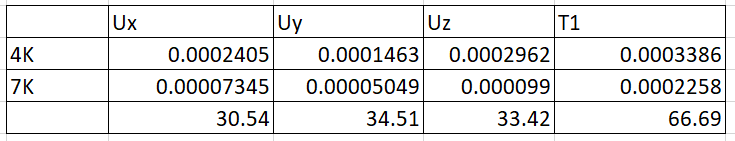

I will suggest to start from a simpler case and try to work your way to more complexity. With a smaller domain, you might be faster in trying to get the optimal sim settings and also to check how T1 behaves with mesh refinement.

Hope that helps,

Kind regards,

Tolga

I will add a few CH to your account, make sure to keep in touch with Tolga so that you have an idea of what you want to simulate as these simulations can get quite expensive in terms of CH consumption. You should have some CH in about 5 minutes

I will add a few CH to your account, make sure to keep in touch with Tolga so that you have an idea of what you want to simulate as these simulations can get quite expensive in terms of CH consumption. You should have some CH in about 5 minutes