Hi Richard (@tenshinshoden),

Your simulation will run much faster (and be more stable) with a first-order mesh but the results will not be very accurate. Sometimes it is beneficial to start with a first-order mesh to get some preliminary results. Then you can do a final pass with a second-order mesh. Please see this post for more details.

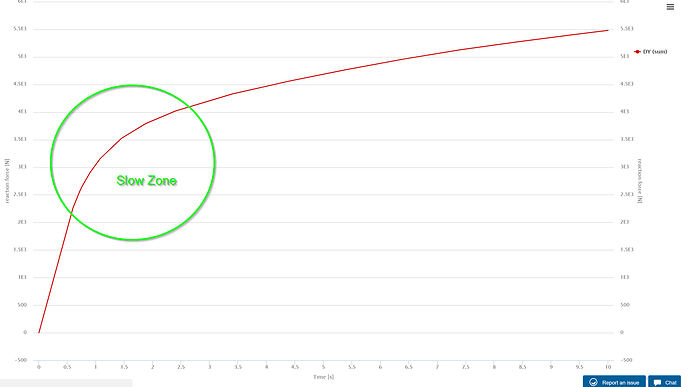

Note that the plastic transition zone (circled in the image below) will take much longer to solve than the bits either side.

Using a coarse mesh will reduce the computation time. You could drop back to one element through the thickness of the pipe but only with a second-order mesh. And even then I don’t expect you will save much, your mesh is already pretty efficient.

I took a quick look at your simulation setup and I can see you are not using the center roller contact (only the support roller). Therefore your non-convergence issue (and possibly long computation time) is probably coming from this contact. You could try to improve this region to make it more stable. For example:

- Provide a larger contact surface area to reduce the local plasticity.

- Change the bottom of the pipe to have a small flat face. This may allow the pipe to slide over the roller more freely.

You could increase the residual (by a factor of 10 or 100) but that would be a last resort. Non-convergence is usually a sign that there is something else wrong and increasing the residual usually won’t help. The default value is generally pretty good for most situations.