Dear all,

Title: Modeling Analysis of Open Cell Metal Foam in Heat Exchangers

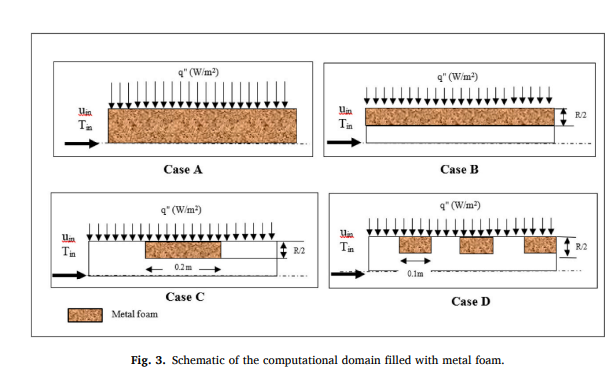

Problem Statement: Metal foam has complex tortuous structure that can increase the heat efficiency and cause a pressure drop.

Objectives: To conduct a simulation on structure of Cu foam and to determine the factor influence on heat transfer efficiency

Approaches: Simulate the heat transfer factor using a complex structure of Cu Foam and compare the available and simulation modelling

May I know how should I start with the simulation?

Is there any public project related to my title?

Best regards,

Jin

Hi @JIN010813,

Thanks for posting your question. I do not remember to see a project similar to this one (and I am not sure if this is possible). Do you already have a CAD geometry uploaded in a project? If so, could you please share the project link here?

best,

Hi,

Thank you for posting on the forum. This is quite an interesting project.

@JIN010813 It seems like you want to simulate a Shell tube heat exchanger where it is partially/completely filled with the copper metal foam. Is that right?

@goncalves Is it possible to find a workaround for this? Perhaps trying to imitate the porous media

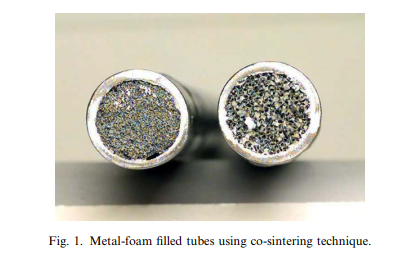

For trial, I want to simulate a Shell and tube heat exchanger where the tube is fully filled with the copper metal foam.

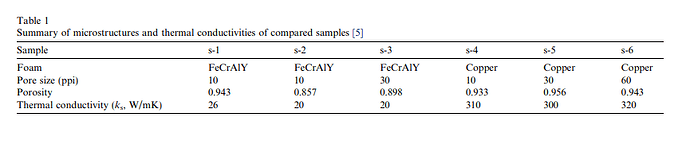

U can refer below for the propertis of copper foam (s-4,5.6)

This is the source of picture:

Thermal analysis on metal-foam filled heat exchangers. Part I: Metal-foam filled pipes:

Hi @JIN010813,

The best option would be combining this kind of porous media (foam) with a heat loss model for the entire structure, but it would be only possible in our next release in first quarter of 2024. For while, an alternative way would be using just our porous media capability analyzing the tubes of the heat exchanger, but this may result in low accuracy in comparison for what you are expecting.

I would suggest to give a try with your results, and then if they are not satisfactory close you can expect it to be completed simulated in the next quarter.

best

Hi @goncalves,

May I know how to apply Porous Media Feature to my heat exchanger?

This is the copied project link:

Unfortunately we do not have any tutorial showing how it can be set, but I would suggest you to create the porous domain (cylinder) to represent the porous media around the tubes, and then set this up in Advanced Concept’s tab. You can also use this project as a guide: Catalytic Converter Flow Simulation with Porous Media by Ali_Arafat | SimScale

But again, I would try it jut with the tube drawing, and then after replicate it using the entire geometry next quarter.

best,