In the context of simulating a pump impeller, I am wondering what would be the physically correct boundary conditions to apply, in order to be able to predict both flow rate and pressure elevation. My first try would be:

- Incompressible simulation

- Steady state

- MRF model for rotating the impeller

- K-Omega SST RANS model (wall functions)

Then it appears the question for boundary conditions for inlets and outlets. Looking at examples, I can see that the usual combo is velocity input + pressure output. But as I do not know in advance the flow rate for a given impeller RPM, how can I know the inlet velocity?

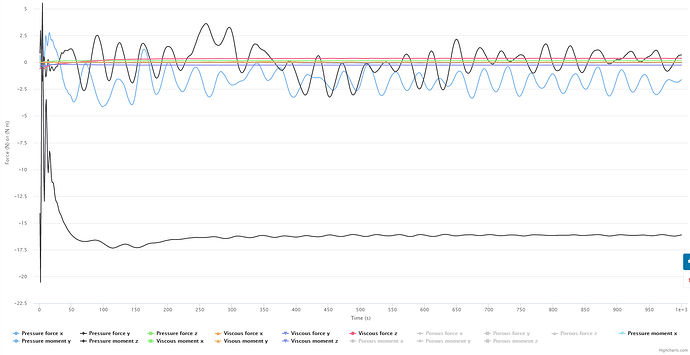

Now, what I did was to perform a simulation with pressure inlet + pressure outlet, both at 0 value, which allowed me to estimate a flow rate in the inlet face (by integrating the normal velocity) for a given RPM, then use this value for a velocity inlet + pressure outlet simulation. This failed in the first attempt with a divergence error, allegedly due to bad mesh elements (which I actually had), but I am not totally convinced, because of the doubts surrounding the BCs.

What I would like to discuss is the physical validity of the BCs, and learn what the valid approach or method is. Here are some questions:

- If I specify the inlet flow rate and an MRF, then what work is the MRF doing on the fluid?

- What new information or insight am I extracting from it if I already know the flow rate?

- Can one correctly predict flow rate without any other input than RPM?

- Is the zero pressure inlet/outlet condition even valid?

- What if the input flow rate differs from the actual flow rate imposed by the impeller? What effect would this have? I know in real life the fluid would move the impeller, or cavitation might occur, but how does this physical discrepancy manifest in the simulation?

I will tag here the CFD Squad, but please, anyone contribute if you have experience or theoretical knowledge on the subject. I know the answer to this might turn out to be trivial or deeply theoretical, but I am sure I and many others will benefit.