Thanks @sjoshi,

Excellent question! I didn’t put anything about cord length in, I should mention it in my next write up!

I think to answer as simply as possible, there are two main things that I considered.

Although I haven’t run a mechanical analysis on my blade designs yet its important to remember that at some point I will have to. Below the max cord length there needs to be enough thickness to support the rest of the blade (you may have noticed a slight thinning in thickness that will be corrected) and this needs to reduce down to a circular profile to attach to the hub. This change in cord length needs to be done fairly sharply to reduce the amount of drag caused by the thick profile and start harnessing the wind from as close to the centre as possible.

To produce energy, what is really happening is kinetic energy is taken from the wind. This means that the air leaves the blade area slower than it came in. To reduce the amount of energy lost due to turbulence, the distribution of slowing needs to be as even as possible. The further the blade from the centre the centre the more air is has to slow.

However, the further from the centre of rotation the more lift a blade will produce due to its increase in relative speed. (n.d. Gurit) In theory the lift can increase with the square of the speed, which is enough to counter its requirement to slow a greater volume of air. The approximate relation of cord length to radius is C=1/R and the matlab script I’ve just created for my next blade design follows this relation however smooths a bit better around max cord length to hopefully better my current design (which started as a sketch).

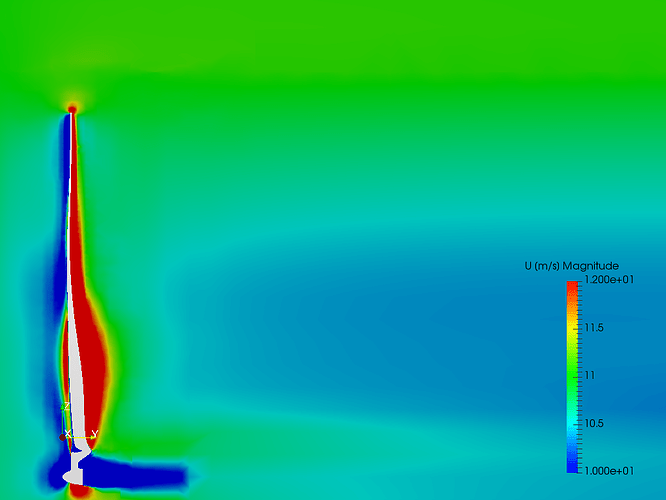

From the shot above it can be seen that velocity has slowed the most approximately 1/3 up the blade, this is where the most wake swirl occurs. I shall consider this further and see what implications it will have on my next design, hopefully with the combination of my Matlab file and the stated assumptions I can make the swirl more uniform. The increase in tip speed should also reduce swirl losses as the required torque will be reduced.

I hope this addresses your question, I really appreciate your comment!

Kind regards,

Darren Lynch