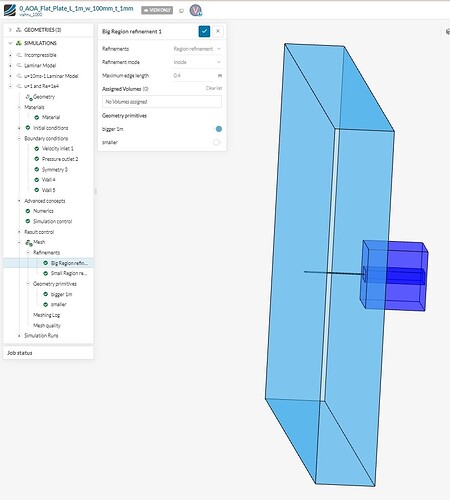

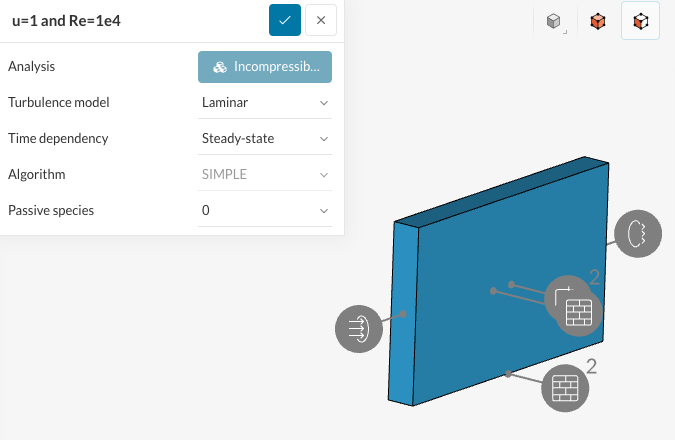

I am working on a simple case of a laminar flow around an airfoil. Following are the specifications:

Flat Plate :

Length =100mm=0.1m

Thickness(ideally infinitesimally thin), here 1mm

Flow:

u=1 m/s, kinematic visc =1e-5, density =1 kg/m^3, thus Re=1e4

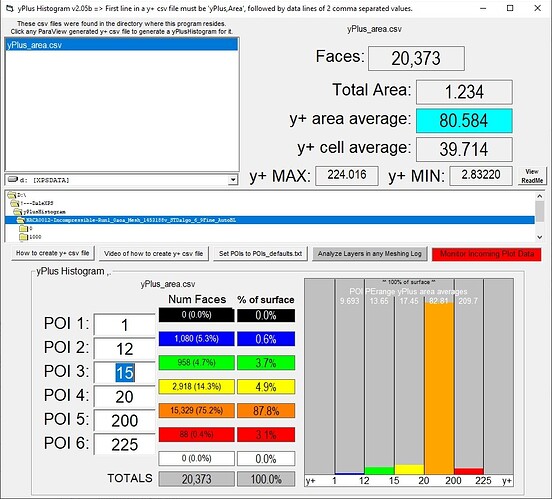

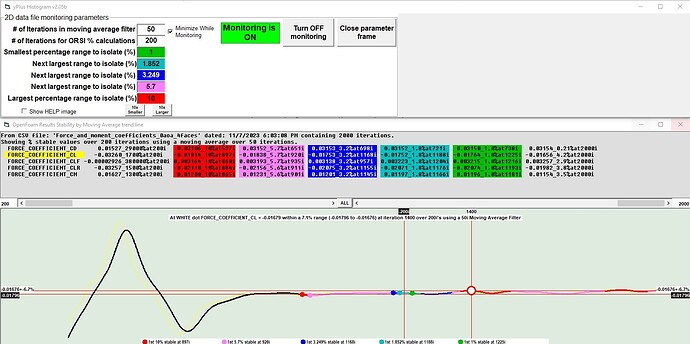

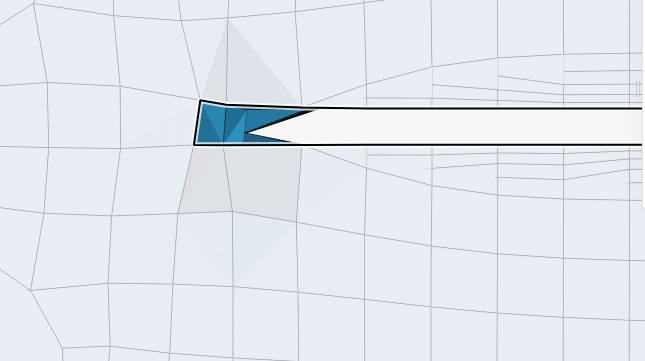

I am trying to calculate the value of drag coefficient whose expected value if 0.0138, whereas I’m getting a simulated value of 0.019, which is larger than expected. I believe this is likely because of ratio of thickness:length is supposed to be even smaller, and I am going to try with even smaller thickness. However, one other possible reason for wrong error is the skewness in the mesh as it it isnt capturing the thickness edge properly. I am using hex dominant mesh for creating the mesh.

For any further details/ simulation set up, following the link to my project(test): https://www.simscale.com/workbench/?pid=8986269944862089602&mi=spec%3A45b1afc6-b77c-42e2-8d56-cdb7d2fa41f9%2Cservice%3ASIMULATION%2Cstrategy%3A38

The above image only shows only one face, as it is a 3D case implemented with symmetry BC on both sides to make it 2D, the skewness goes all along the thickness edge.

Even if I am using another CAD model with even smaller thickness, I am sure that I will encounter the same problem. It would be great for someone to tell me what could be done?

Thanks,

Vishnu