Hello,

I’ve simulated a three cube one inside another to emulate the heat transfer between an aluminium cast piece at 600-700ºc approx (nucleus, smallest cube) and the mould structure (second cube) and the air (the biggest one that are an enclosure). And all was ok

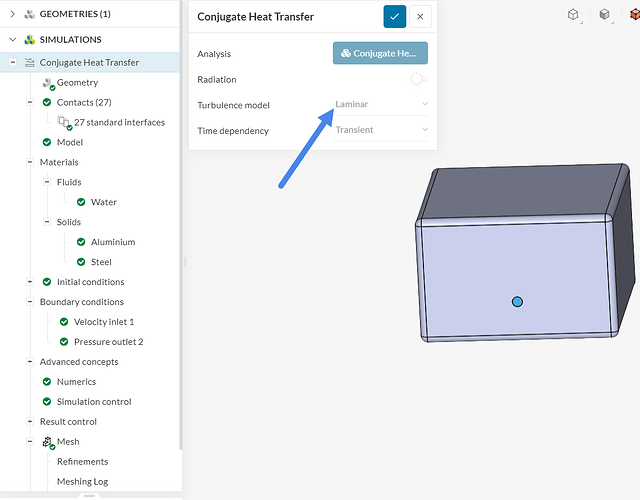

Now I’ve deleted the air enclosure and added a hole inside the mould for simulating a water flow inside acting as a cooling tube. The other cubes are like the explained above (aluminium cast piece at 600-700ºc approx (nucleus, smallest cube) and the mould structure (second cube)).

The problem is that the simulations take so long time and don’t progress. I’ve simulated 230 minutes and it didn’t reach the 2%. I’ve reduced the mesh and the End time simulations but i’t was useless. How can I fix it?

I attach the first project link and the second one:

The second one is where the problem explained is:

Thanks for all.