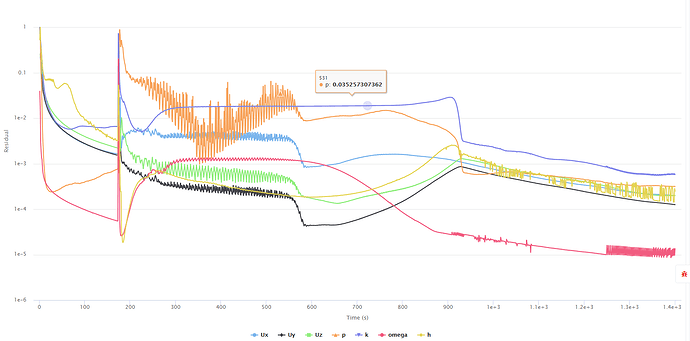

I am currently working on an engine port flow simulation problem but am facing some issues in convergence of my results. I am not able to understand the reason of sudden jumps in the residual values. i would be highly obliged if someone can help me with this problem.

I am also attaching the link to my project-

https://www.simscale.com/projects/anirudh2821998/engine_port_flow_simulation/

Hi @anirudh2821998,

Compressible simulations tend to be very sensitive to mesh quality. Try adjusting the numerics and using first order schemes with a high degree of numerical dampening.

Specifically change the gradient to cell limited gauss linear and see if that helps convergence.

You also might want to post-process your simulation to see where the regions of numerical anomalies lie so that we can see whether they are able to be tackled or not.

Cheers.

Regards,

Barry

Hi,

I would like to add 2 more points.

-

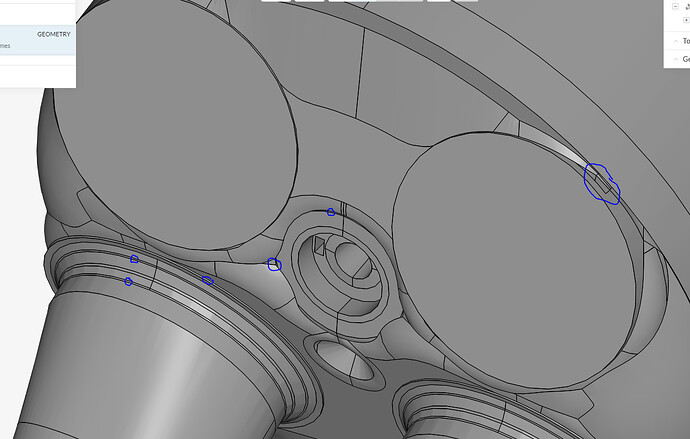

Please try to eliminate the tiny faces in the geometry and simplify it a bit. They can be problematic for meshing.

-

If possible, try using Velocity Inlet / P_outlet combination.

Regards,

Rajan

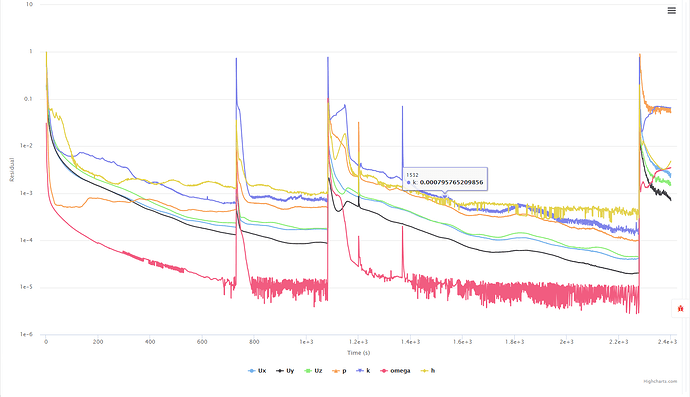

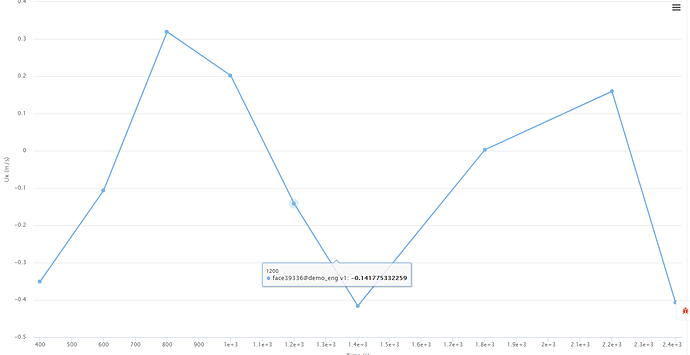

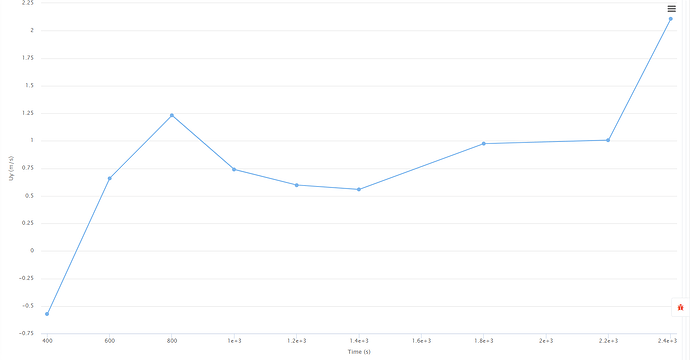

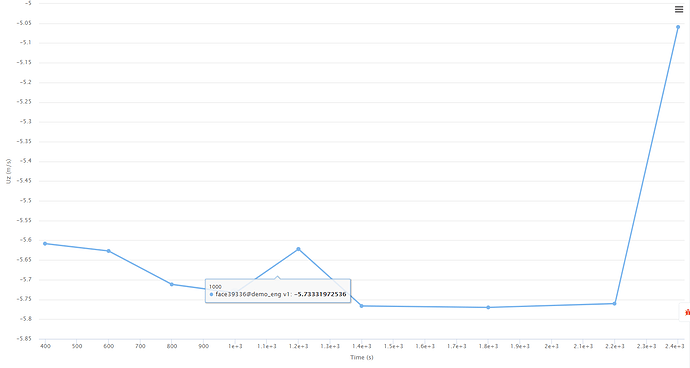

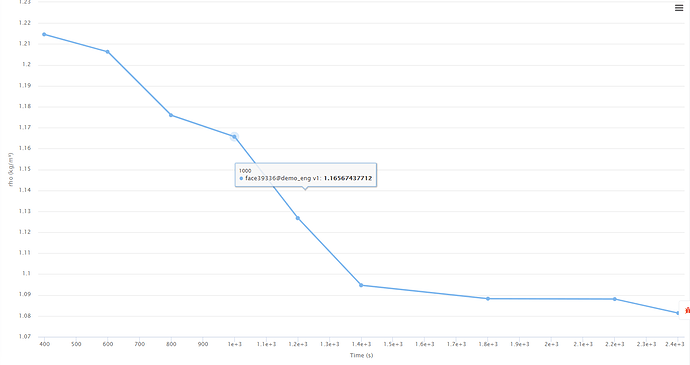

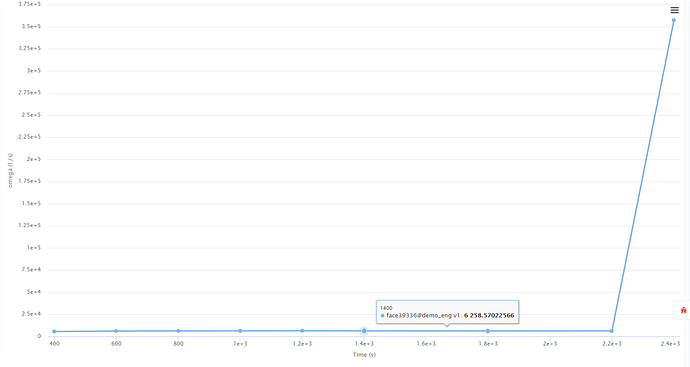

Hi, i tried to simulate with better mesh quality and I am attaching the convergence report below. If I am not wrong, then, It seems that the solution has converged as all the residuals has come under 1e-3.

@rajan19us I cannot use the velocity inlet boundary condition as I don’t have any data regarding the air velocity in the inlet port at 90KPa vacuum condition. Thus, the best idea in this situation was to first simulate with pressure inlet/pressure outlet condition and get a rough idea of the velocity in the intake port and then I can further use that information to complete a new simulation with inlet vel/outlet pressure boundary condition.

Hi Anirudh,

I am afraid that the simulation is not converged. yet Are you expecting max. velocity of 110 m/s?

Also, have you verified your boundary conditions? at inlet atmospheric pressure and at outlet 0.9 bar. What are you trying to achieve here?

This link could help you: OpenFOAM: User Guide: Common Combinations

Regards,

Rajan

Hi @rajan19us

Yes the intake air can easily achieve a velocity above 120m/s in the valve proximity area and I will give you a proof of this within a minute(or may be within 5mins ![]() ) This simulation tries to study how efficient your engine port design is? The engine flow bench is used for analysing the engine port(may be intake or the exhaust) in which a vacuum pump attached at the end of the cylinder sucks the air through the port with intake valve at a specific lift. So in order to replicate the flow bench I have given inlet pressure of 101KPa and 90KPa on the outlet face. which means that the air will now flow through the cylinder due to a pressure gradient(replicating the vacuum pump). At different valve lift you will get different outlet mass flow rate and you can compare how your air behave at different lift. I am attaching a video of air flow bench, which may help you in better understanding of my objectives.

) This simulation tries to study how efficient your engine port design is? The engine flow bench is used for analysing the engine port(may be intake or the exhaust) in which a vacuum pump attached at the end of the cylinder sucks the air through the port with intake valve at a specific lift. So in order to replicate the flow bench I have given inlet pressure of 101KPa and 90KPa on the outlet face. which means that the air will now flow through the cylinder due to a pressure gradient(replicating the vacuum pump). At different valve lift you will get different outlet mass flow rate and you can compare how your air behave at different lift. I am attaching a video of air flow bench, which may help you in better understanding of my objectives.

And if I talk about convergence, then my Ux, Uy and Uz residuals have already reached 1e-3(which is sufficient for most of the simulation) and my omega residual value is about to reach 1e-5.

Link- Differential Flow Field Analysis in Engine Development (AVL Tippelmann + LaVision) - YouTube

Thanks

Ani

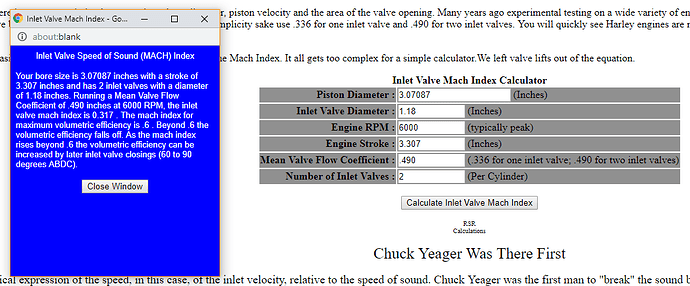

Hello sir, you can have a look at this Intake air mach number calculator- Inlet Valve Mach Index Calculator