Hello SimScale community,

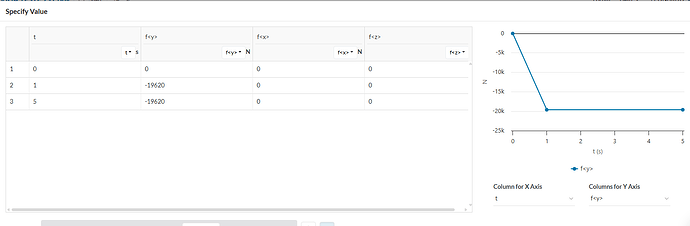

I am currently trying to simulate a Shore 45A indentation test of a silicone block using the nonlinear mechanics solver (Marc). Test setup Durometer: Shore durometer - Wikipedia

Goal is to penetrate the indenter by 1.4mm and then measure the reaction force.

Setup so far (one example):

-

Material: Mooney-Rivlin hyperelastic (Shore 45A estimated parameters: C10 ≈ 1.6e6 Pa, C01 = 1.6e5, K ≈ 5e7 Pa, ρ = 1120 kg/m³).

-

Indenter: rigid punch, displacement-controlled z: -1.4 * t mm (but it usually aborts after 0.5-1mm)

-

Contact: frictionless, automatic penalty.

-

Mesh: 2nd, locally refined under the indenter.

-

Simulation control: End time = 1 s, Initial = 1e-4 s, Max = 1e-3 s, Min = 1e-9 s.

-

Boundary conditions: block bottom fixed in Z, sides free. Block size ~2× indentation depth, ~1.5× contact radius. (I chose a very reduced version to be able to have a finer mesh)

Problem:

The simulation repeatedly fails with

“Automatic time stepping led to a timestep below the minimum threshold”.

I have already tried:

-

Decreasing max timestep,

-

Using smoother displacement ramps,

-

Mesh refinement under the indenter and the soft silicone surface

-

Frictionless contact only.

Questions:

-

Are there recommended time-stepping settings for hyperelastic indentation in SimScale?

-

Does my block size (2× depth, 1.5× radius) cause artificial confinement effects?

-

Is there a way to make the run more stable without exploding computation time (e.g. mesh strategy, solver settings)?

-

Has anyone successfully simulated Shore A hardness tests (or similar rubber indentation) in SimScale and could share best practices?

Link: SimScale Login

Any hints or example projects would be greatly appreciated!

Thanks in advance,

Peter