Hi Folks,

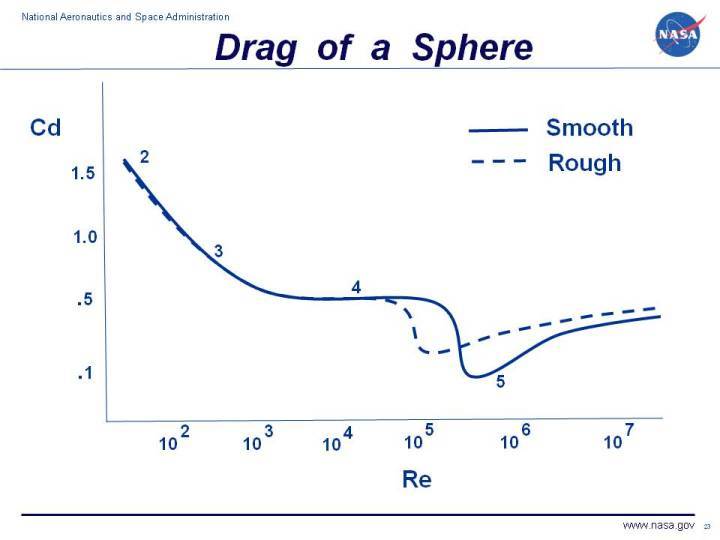

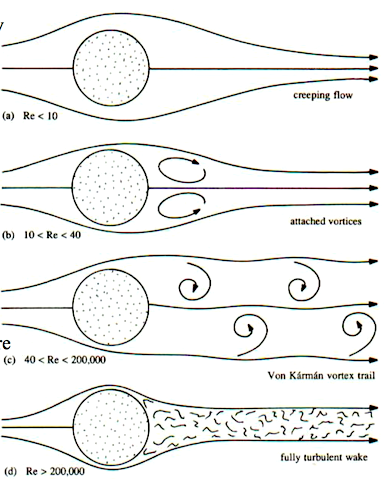

I’m trying to do some simulation work around small (1m-10m) airship drones. In order to calibrate things, I thought I’d try to run a series of flow simulations around a 1m “unit sphere” at different Reynolds numbers, in order to try to replicate the well known experimental results along the lines of:

(I’m using Reynolds number as velocity * 1m * 67,567 - is this correct?)

However I’ve had a lot of trouble reproducing these results. In particular I was hoping to be able to reproduce the classic Cd = 0.5 plateau that spans from 103 to 105. To this end I set up a 1m sphere and ran sims with inlet speeds of 0.015 m/s through to 15 m/s, which (I think?) should roughly correspond to Reynolds numbers of 103 through to 106.

Unfortunately my results seem to be nowhere near the experimental results, so I suspect I’m setting up my BC badly!

Reynolds # ~= 1,000

sphere 1m radius: 0.015m/s - drag 0.000264 - Cd ~= 2.5 (k-omega SST)

Reynolds # ~= 10,000

sphere 1m radius: 0.15 m/s - drag 0.00619 - Cd = 0.58 (k-omega SST)

(sphere 1m radius: 0.15 m/s - drag 0.00383 - Cd = 0.36 ?? (LES Spalart - Allmaras) )

Reynolds # ~= 100,000

sphere 1m radius: 1.5 m/s - drag 0.366 - Cd = 0.345 (k-omega SST)

Reynolds # ~= 1,000,000

sphere 1m radius: 15 m/s - drag 32.26 - Cd = ~0.304 (k-omega SST)

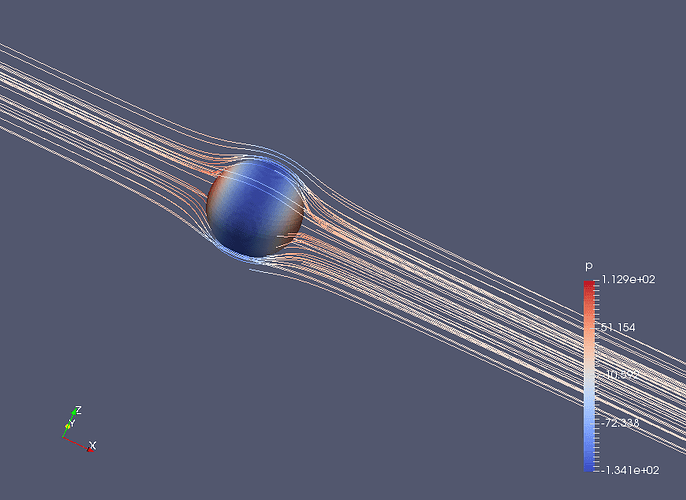

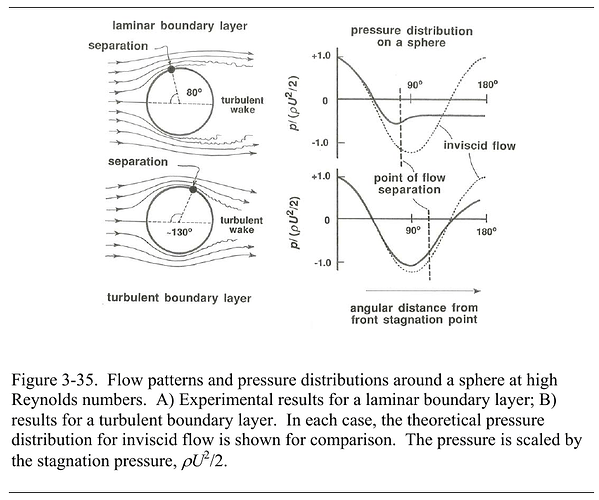

Any ideas on how I should proceed? I think my problem is lack of separation; when I look at the stream lines for all these simulations, they seem to wrap very closely around the back of the sphere; I don’t see any signs of the turbulence or eddies I would expect -

Boundary Conditions for all runs are:

Inlet velocity 0.015 - 15m/s

outlet pressure 0

walls - slip - zero gradient

sphere - no slip - zero gradient

material - ‘air’ from database

analysis type - incompressible - k-omega / transient / PIMPLE (tried LES Spalart - Allmaras once but didn’t seem any better).

Drag calculated in paraview by extracting the sphere as a block, generating normals, calculating normal_x * pressure and integrating…

Any advice gratefully accepted, I’m afraid I’m a complete newbie at this stuff, so most of my values were copied from one of the public car simulations :-)! I suspect I’m not setting things up to model turbulence correctly, as I don’t see any sign of it in the flow calculations, and many of the sphere models show a large ‘-ve’ drag on the rear of the sphere…

cheers,

- Chris