Description

The objective of this modeling effort is to demonstrate that SimScale can be used to deisgn a 2" wall PUR shipper that would hold a product temperature of 2 to 8°C for a 96 hour summer cycle. The design consisted of the following component:

- Qty 1, Molded PUR base [OD=20.5"(L)x19.88"(W)x21.63"(H)]

- Qty 1, Molded PUR lid [OD=20.5" (L)x19.88"(W)x21.63"(H)]

- Qty 1, Molded PUR inner box [dimensions 14.5"(L)x13.88"(W)x19.5"(H)]

- Qty 1, Corrugated Product box [ID=11.13"(L)x10.5"(W)x16.5"(H)]

- Qty 12, 338F Refrigerant Brick [Dimensions 11.5"Lx8.88"Wx0.75"H]

- Qty 8, 339F Refrigerant Brick [Dimensions 11.5"Lx85.445"Wx0.75"H]

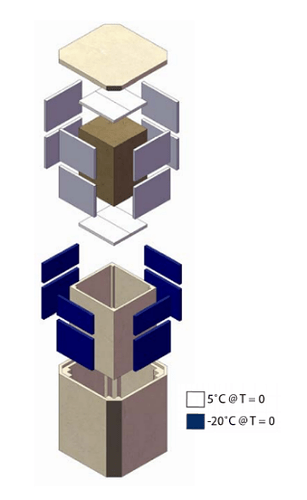

In this shipper design, temperature is passively controlled by pre-conditioned frozen (-20°C) and liquid (+5°C) refrigerants in combination with an insulated polyurethane (PUR) foam container (with inner box). An exploded view of the PUR shipper is shown below:

For the PUR components, all pre-conditioning is done at room temperature (+22°C) for a minimum of 24 hours. As shown in the figure a total of twelve 338F bricks were used, eight refrigerated (+5°C) surrounding the sides of product box and four frozen (-20°C) surrouding the bottom of the PUR inner box. A total of eight 339F bricks were used, four refrigerated (+5°C) on the top/bottom of the product inner box, and four frozen (-20°C) surrounding the top of the PUR inner box. Without product, this design weights ~55 lbs, inlcuding 28 lbs of refrigerated bricks (+5°C) and 17 lbs of frozen (-20°C) bricks.

The geometry of the shipper must be prepared using CAD software. To limit the simulation model size, a 1/4 size model can be used.

Purpose

The purpose of this case is to validate the SimScale CHT solver for thermal packaging design.

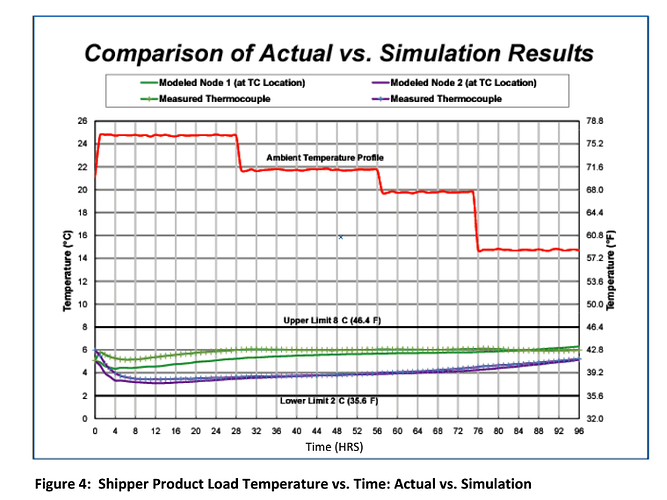

The results to be achieved are like in the next figure:

Following the temperature profile showed in the red curve above, the temperature must be measured at the bottom and the middle of the product box as a function of time (lines green and purple).

Key Words

Thermal Packaging, CHT for thermal packaging design, thermal shipper design.

Reference

Status