Perhaps I am using a rather unorthodox approach of uploading photogrammetry meshes for CFD analysis, which are processed in Meshlab and Meshmixer. The other perhaps unorthodox aspect is that since I am trying to obtain drag coefficients of cutting armatures (arrowheads essentially) I am including a tube that extends to the back of the computational domain as a stand-in for the trailing shaft. This is attached in Meshmixer. The false shaft and armature are left as separate bodies so Cd can be isolated on the armature. This is in a viscous Newtonian incompressible at 25-40m/s.

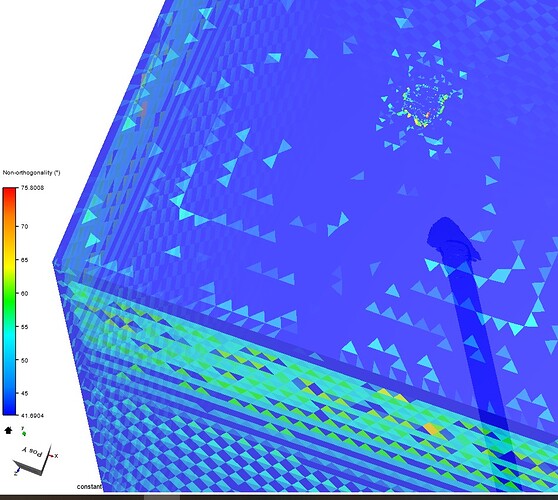

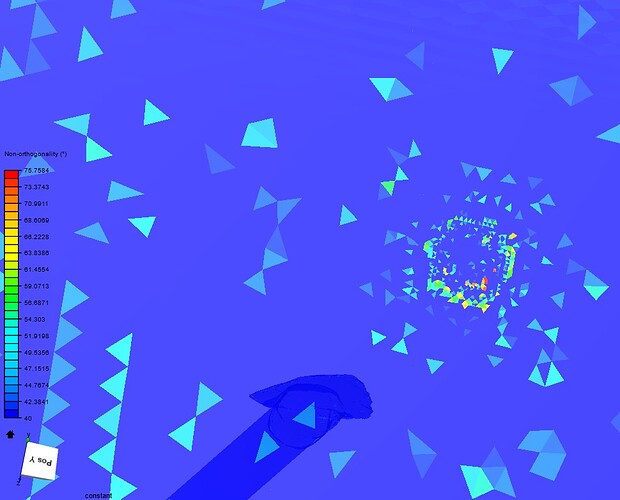

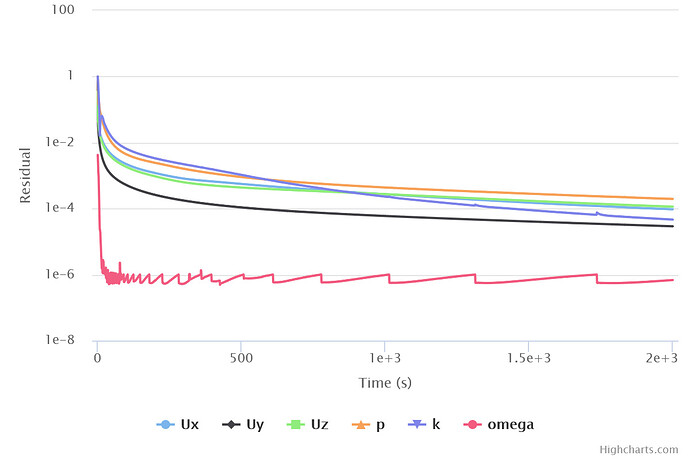

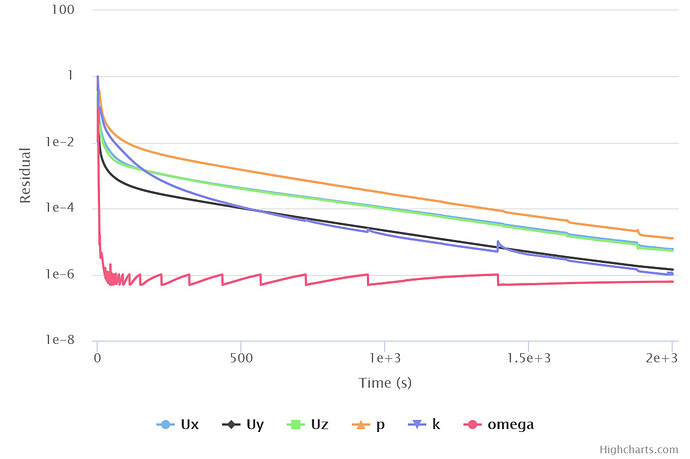

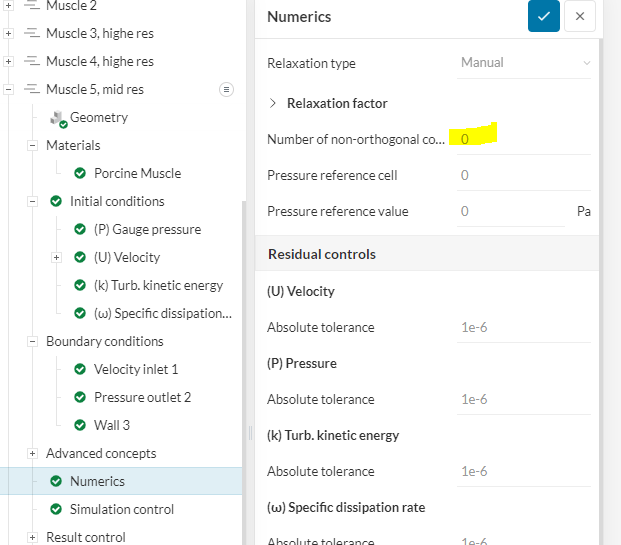

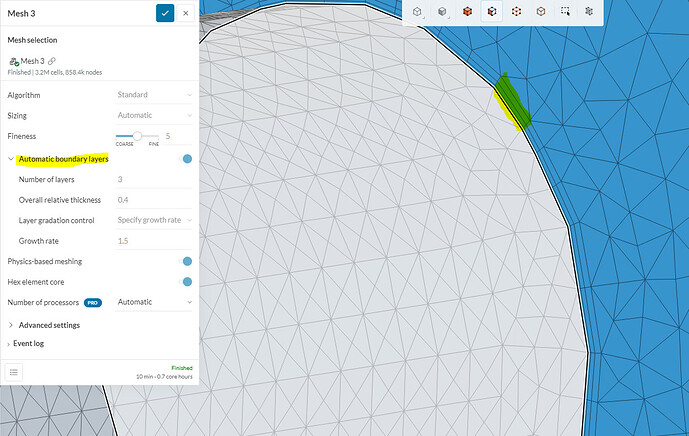

Finally after solidifying in meshmixer with >.2mm thickness SimScale does not complain too much about the models. But since I would like to achieve convergence in my lifetime and without hogging more computer power than necessary I apparently have to try and fix nonorthogonality >70 in the generated meshes using the SimScale standard mesher, and hope this is almost the final step to have stabilized Cd measures. It is hard to find documentation on how to do this that doesn’t involve going back to cleaning in the CAD software. There appear to be only a few mildly troublesome spots on the models I could potentially resolve, but through the quality checker I am seeing that actually the most troublesome areas are in the enclosure! I cannot find anything on how this should be resolved. Ideas?

Muscle 5 mid res provides a good example (https://www.simscale.com/workbench/?pid=6836371537479817522&rru=0121a3c6-66ea-4e9e-b727-a806e42f1cac&sh=33&ci=59cd26a6-0bb0-455e-acbd-2bcb7efbcfa1&ct=MESH&mt=SIMULATION_RESULT)

tetAspectRatio max=8

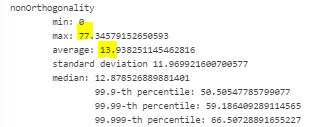

Non-orthogonality max=77

tetEdgeRatio max=7

volumeRatio max=10