Hello All,

I am a senior Mechanical Engineering student seeking help on a simulation I am trying to run. Me and a team began working on our senior project and due to covid had to take a different approach at testing our designs for our impact attenuator for a formula 1 car. We want to test our design in simscale to see how it will deform upon impact.

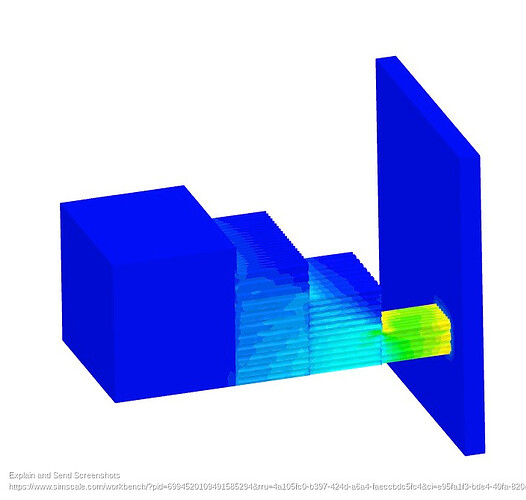

During testing we ran into many errors but one error has proved to be most difficult to figure out the cause. Simscale produced a simulation but the attenuator is passing through the wall that its suppose to smash into as if it is not there. Some of the Simscale employees Ive been in contact with seem to think its a time-step issue but we have been unable to resolve the problem.

Below I have included a link to the project. I invite anyone and everyone help me with this problem if you’d like to. Please leave a comment if you need more information and any help is greatly appreciated!!

Thanks,

Chris Lambert

Link: https://www.simscale.com/workbench/?pid=3802283857931706343&rru=aa2d87c5-a80c-4fc5-a2ca-e145b05c7bed&ci=0940ce47-27a6-4ed6-a8bf-c92957ddf0e8&ct=SOLUTION_FIELD&mt=SIMULATION_RESULT

1 Like

Hey @clamb005!

Use this project as a reference: - I am tagging the @fea_squad to help you out.

Happy weekend!

Jousef

1 Like

Hi Chris!

There are two changes that I currently suggest to try and fix the simulation:

First one is to modify the model and simulation setup to follow the guidelines given in this KBA: Set Up the Time Step for a Dynamic Impact Analysis | SimScale

Second, you really need to improve your mesh quality. By inspecting your project, I can see that your maximum aspect ratio is 187.7, which should be more like < 10, ideally < 4. These thin walled parts require very fine meshes to capture all the local bending deformations. You can achieve this by using finer mesh settings.

1 Like

Hello @clamb005,

I wanted to check with you to see if you have had any luck with your problem?

I did some quick changes to your model and I was able to get it to run… until I exceeded my execution time.

The model still needs work but you can take a look at it here if you want.

Christopher

3 Likes

Hey! Thanks for taking a look! unfortunately I am still unable to get it to run I was told it could be a problem with the mesh, the CAD model itself, or the physics. Yours is the only one Ive seen run so thats an improvement! The only thing I think would have to change in yours is that the aluminum material has to have plastic behavior. I appreciate you looking at it and any updates you have would be greatly appreciated!