Computation Fluid Dynamics

Analysis Type: Passive Scalar Transport

Turbulence Type: Laminar

Solver: PIMPLE

Number of Cores: 4

Simulation Time: 22.5 hours

This is a really cool project of a 3-inlet, 1-outlet mixing diffuser for juice flushing. So what is juice flushing you may ask? During the juice making process, each time a new batch is made, the tank must be flushed out with water so that the flavors from the first batch do not contaminate those of the new batch.

To make this an efficient process, a 3-inlet tank system is used. Water enters Inlet 1 continuously. The juice product can enter the system from Inlet 2 or Inlet 3 which can be switched ON and OFF.

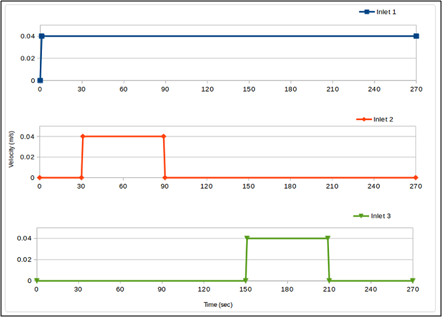

The Inlet flows can be viewed in the graph below. At time=0s, only water enters the system through Inlet 1. At time=30s, inlet 2 is turned ON and juice (let’s say it’s apple juice) enters the system combining with the water from inlet 1 in the mixing tank. At time=90s, Inlet 2 is turned OFF meaning the first juice batch is complete. Now the tank must be flushed so only water flows through the system for the next 60 seconds. At time=150s, Inlet 3 is turned ON and apple juice again enters the system. At time=210s, Inlet 3 is turned off and again only water is flowing through the system.

To see results of the velocity fields, scalar mixing distribution, and pressure at different times during the process, you can go directly to the project here.

Check it out and let us know what you think; what other processes could this be useful for?