Hi all, I am trying to design a “velocity stack” that would improve flow into a carburetor.

Here is the baseline (carburetor intake shaft, and a pancake filter) :

Here is a standard design that is proven (on physical flow benches) to provide higher flowrates:

And here is my design:

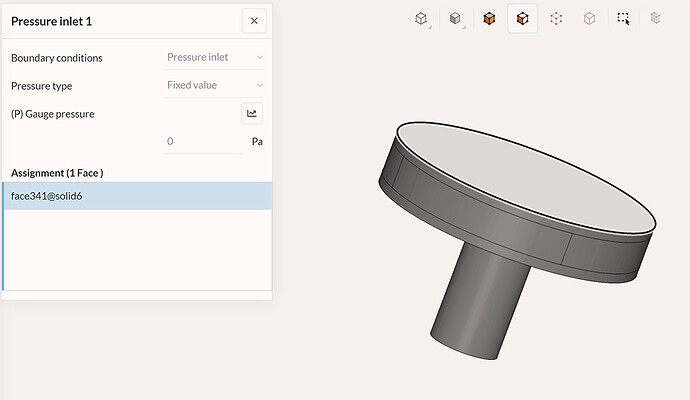

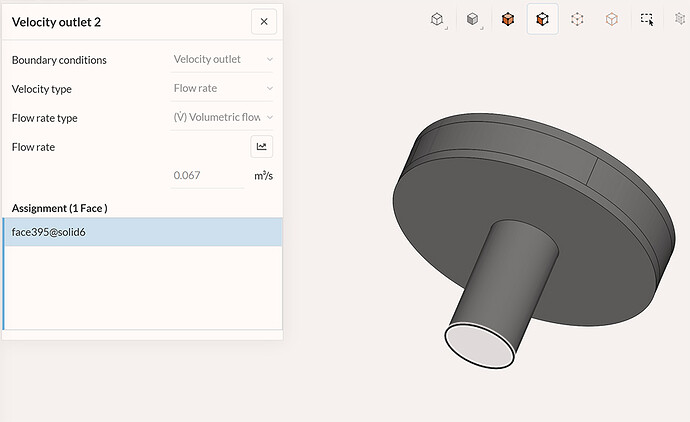

I did a couple runs of each and mostly with these settings:

Inlet

Outlet - this is the flowrate for an HS4 Carb

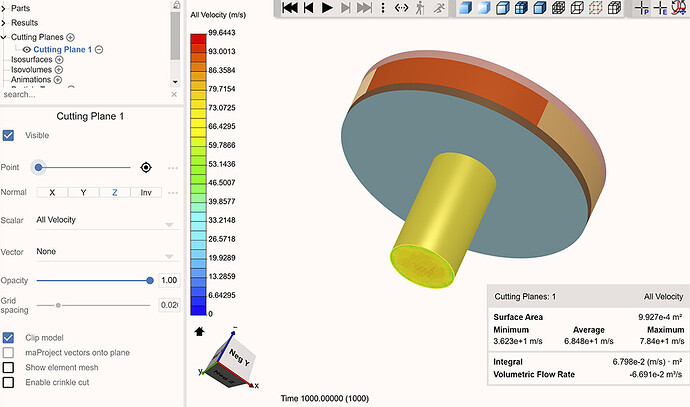

I’m using the cutting plane to find the numbers, and I’m just looking at the m3/s flowrate as the result.

Using that number, the “stubstack_standard” provides an 13.6% increase in flow (should be around 5% on a flow bench), and with my design getting 82% increase in flow over the baseline. Which is too good to be true. I must be doing something wrong.

Thanks in advance for any feedback. I’m a total noob and never studied this; I don’t even know what e-2, e-3, etc means. I just hope with some accurate numbers, I can get more power out of my cars.