Hi im looking for examples of how to set up the loading for a wing stress analysis for a light aircraft. I have done this by hand and am familiar with it but i haven’t done a full wing before in FEA. im trying to figure out mainly what is the best way to apply the loads and bending moments as well as the wing torques any body else done this in SimScale?

Cheers

Michael

Hi @MHHS!

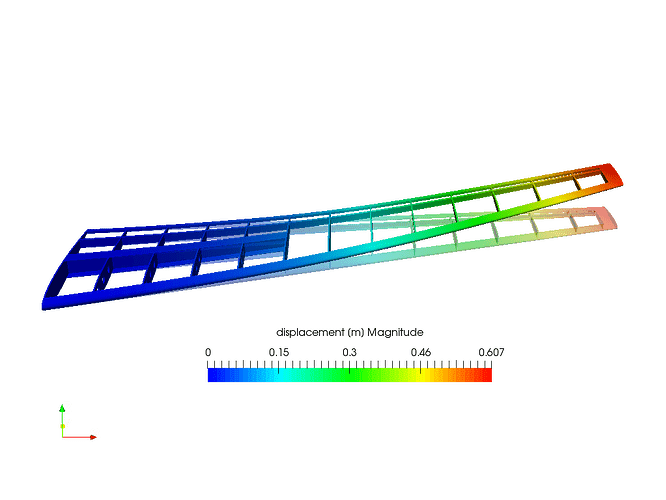

I have set up a simulation here: Aircraft Wing - FE Analysis

Feel free to share your thoughts about it and if you would optimize something. Also see in the simulation setup that I defined a point which I put into the result control giving the maximum deflection.

Cheers and happy SimScaling!

Jousef

Hi Jousef,

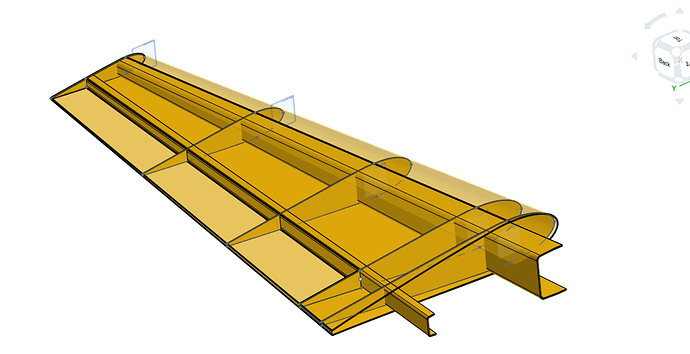

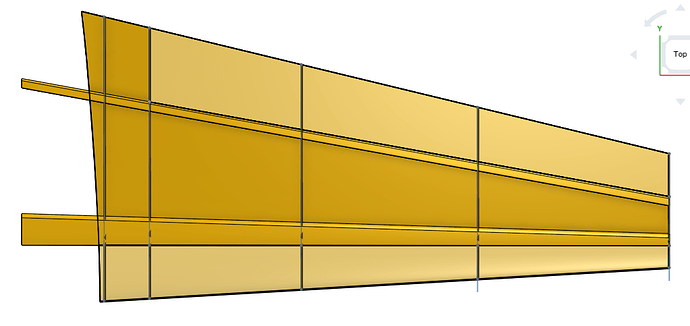

Interesting model ! thankyou for posting. my plan is analyse a composite aircraft wing for a light aircraft i am designing. the plan is to build and fly it at some point! any way i have done a fair bit of textbook stress analysis using spread sheets but i would like to model it all up in FEA as these methods are somewhat conservative. I will post updates and progress as i go …anyway here is the wing config i will analyse

these images are from the Onshape model. The plan is to build the wing out of molded carbon fibre construction and the purpose of the stress analysis is to determine the thickness of the composite layup to ensure strength and light weight.

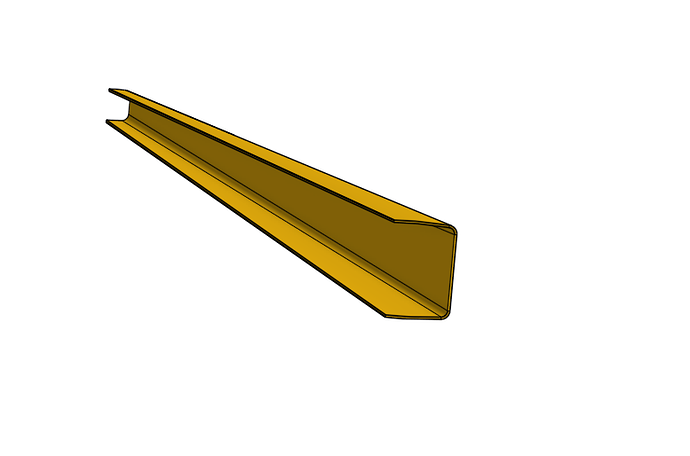

The wing is subject to a Air load distribution which gives a span wise shear force distribution and bending moment distribution as well as a constant nose down pitching moment (torque) that acts through the 1/4 chord line. As a first approximation We assume that the main spar carries all shear force and bending moments. and the skins and ribs carry the torque loads.

here is the main spar

and here is link to the mesh and geometery this is only really a preliminary FEA analysis that i have done to get used to and learn SIMSCALE here is the link to the simscale model https://www.simscale.com/workbench/?pid=1217919946814898973#tab_0-0

Cheers Michael

Awesome model, did you use my aerofoil script?

Kind regards,

Darren

Very interesting model you got there Michael (@MHHS), love it!

Just want to let you know that composite materials are not yet possible to analyze inside SimScale. I would still love to see how you do a simulation on your components as you already did on the spar!

Do you need any help for that so far? Just post your updates in this thread. Want to share it in our Project Spotlight section

All the best and keep going Michael!

Jousef

for this wing no sorry…but i have used it for other wing models i have made and its great!. there is thread on the onshape forum showing some screen grabs of one wooden wing i have done using the airfoil script its very user friendly!. This wing uses a special symmetrical aerobatic airfoil section that is pretty much flat after the 1/4 chord point. i had data to construct it from a sketch rather than data points. The tail surfaces (not shown) use it to. Thanks alot!

Im interested in any help! thanks!..Is it possible to input properties for a single orthotropic material in SIMSCALE instead of modeling each separate ply in a layup?. I have seen some texbook examples of real world composite light aircraft wings that were designed in the early 90’s using fairly primitive FEA software on a pc. The plan is to not go too far into optimising the structure at this stage just to make something strong and not too heavy

cheers

Primitive huh?  In the mid 90’s I worked at Boeing and I was a structural analyst working on a new fan for their transonic wind tunnel using composite fan blades. At the time there were several commercial codes and one out of Livermore Labs that would take your composite layers, fiber orientation, and material properties and convert it to isotropic or anisotropic material properties. I am sure everything I used has been absorbed by some other company by now but the capability exists.

In the mid 90’s I worked at Boeing and I was a structural analyst working on a new fan for their transonic wind tunnel using composite fan blades. At the time there were several commercial codes and one out of Livermore Labs that would take your composite layers, fiber orientation, and material properties and convert it to isotropic or anisotropic material properties. I am sure everything I used has been absorbed by some other company by now but the capability exists.

Good luck and if I can find any names of software I will let you know.

Christopher