Hi! Can you do me a quick favor!?

I’m in the middle of installing windows on my van and I would like to prop them up so they can open up all the way (kind of like DeLorean doors).

I’ve gone to metal supply stores to figure out which material is the stiffest, but they don’t have everything in stock so it’s becoming very time consuming.

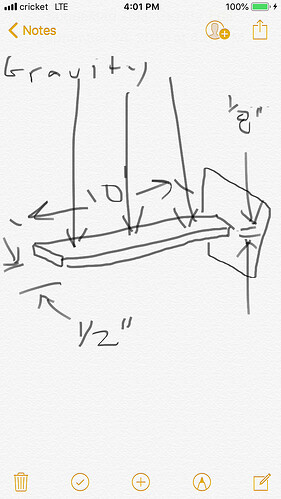

The mechanism that will hold up the window is about 1/8”X1/2”X30” and it will be at about a 45° angle and will hold up about 20 pounds. I’m afraid that the metal will bow sideways since it’s only 1/8” thick.

At the metal supply stores I compared two 12 foot lengths of metal and tried to see which one was stiffer and believe it or not it seemed to be the 1018 cold rolled steel when compared to the 304 stainless steel. I bought the 1018 cr steel, but I still feel like it’s too flexible.

Do you think you could do a simple test for me? I’ve never used this software before, but this should be super easy for you!

If you have a beam that’s 10 feet long by 1/2”X1/8” that supported on one end and positioned horizontally, so that gravity can act on it in a strong way how much does it deflect? Can you set up the experiment so that gravity is pushing on the thin side so that it flexes a lot?

Can you tell me which material causes the beam to flex the least? Is it 1018 cold rolled steel, A36 hot rolled steel, A2 tool steel, D2 tool steel, O1 tool steel, 304 stainless steel, 304L stainless steel, or 303 stainless steel?

My guess is that since all the materials have pretty much the same modulus of elasticity they will deflect the same amount until each one reaches its yield point then the deflections should vary quite a bit after that. I’m guessing a tool steel will be the winner, but what do you think? I would love help on this because I’m in the middle of cutting a hole in the side of my van right now and don’t have time to learn how to use a new software.

If you can help that would be great, if not then I totally understand! Thank you!

And gravity can of course be added to the simulation by going to the “Model” item of the tree and set the corresponding right direction for gravity.

And gravity can of course be added to the simulation by going to the “Model” item of the tree and set the corresponding right direction for gravity. We are here if you need us!

We are here if you need us!