Thank you very much @ggiraldo and @BenLewis ! Your help is really valuable, especially your explanation @BenLewis. However, I still have some doubts on your rubber approach. I’ve been studying it deeper lately now I have your information in order to use it my studies, maybe I use something similar in my frame analysis. Below you can see my approach, I try to avoid using physical contacts since I would like to keep it linear and easy to simulate, since this is my first multi body analysis.

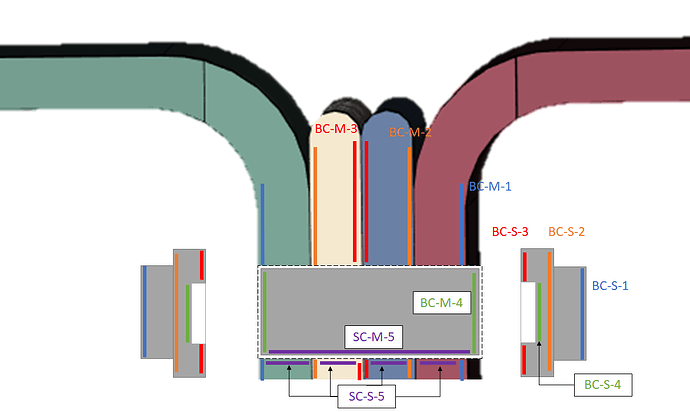

Pin and rubber approach

Contact specification

Contact Code:

- BC-X-X: Bonded Contact;

SC-X-X: Sliding Contact - XX-M/S-XX: Master/Slave

- XX-X-Y: Yth contact

If I understood well your Crane case, my approach would be more or less similar to yours since I only replaced your physical contact between the pin and the inner hole faces by a sliding contact. What do you think about it? Would it work?

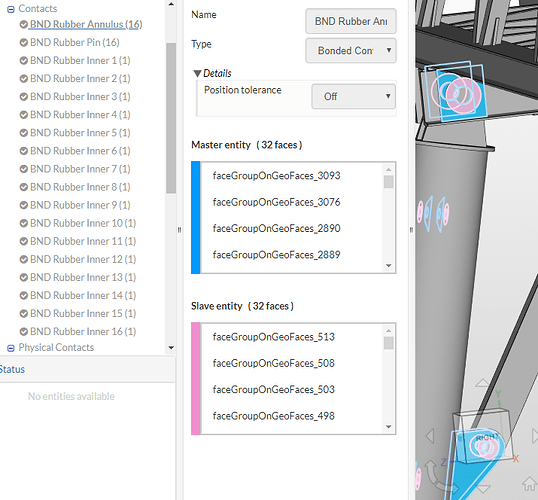

Besides that, as I already mentioned, I still have some doubts on your implementation of the contacts in your case, let’s see a figure,

When you define the contacts between the outermost faces of all the junctions and the rubber elements (BND Rubber Annulus) you do it in a single contact constraint. And you do the same process for the planar faces of the pins and the rubbers (BND Rubber Pin). However, when you define the artificial contact between the rubber parts and the faces of the inner part of the junction you do it one by one, beeing each one in a single contact constraint (BND Rubber Inner). What is the reason for doing so?

Regarding your suggestion

What do you think about my initial approach which I think is similar to what you suggest? Below you can find a quote of my own

Would you recomend this use of Bonded Contact constraint for the bolts? Or would your approach be better? I guess I already know your answer…![]() However, I would like to know your opinion about my approach.

However, I would like to know your opinion about my approach.

Don’t worry, I understand you are a busy man. I don’t mind waiting for an answer if it as good as yours has been! ![]()

Regards,

Alex