From aerospace propellers to turbomachinery, valves, and general industrial equipment, ensure your design’s efficiency without ever leaving your web browser.

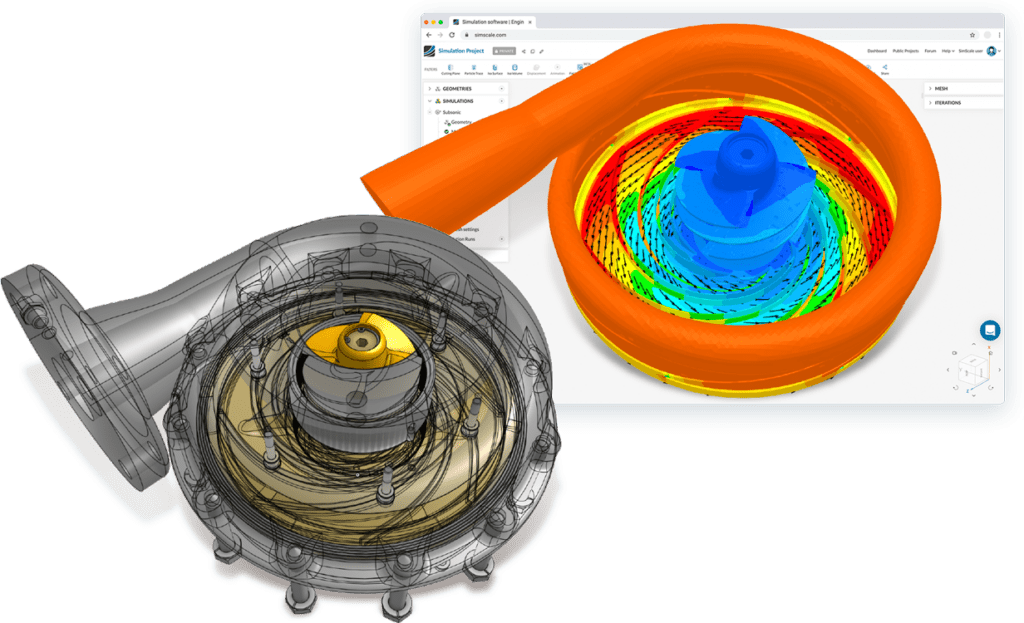

SimScale imports SOLIDWORKS, Inventor, Onshape, and other common files. Meshing is automatic.

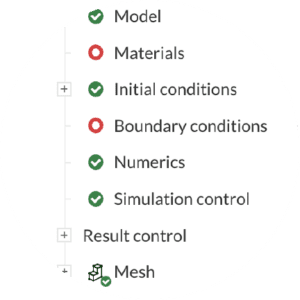

Choose your analysis type, set up your conditions, and start simulating!

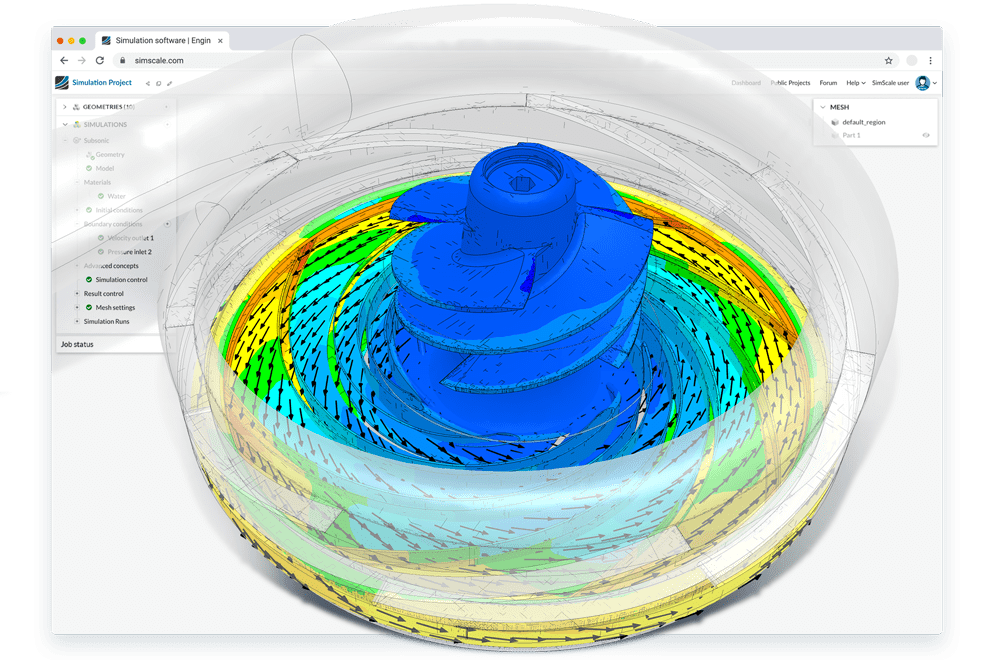

Analyze your simulation results with SimScale’s integrated online post-processor.

Get access to a high-fidelity engineering simulation platform that is technically and economically accessible for designers and engineers, at any scale, in the cloud.

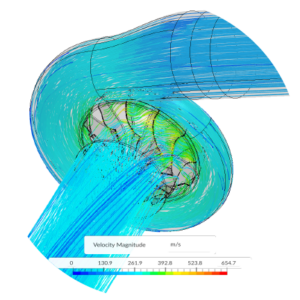

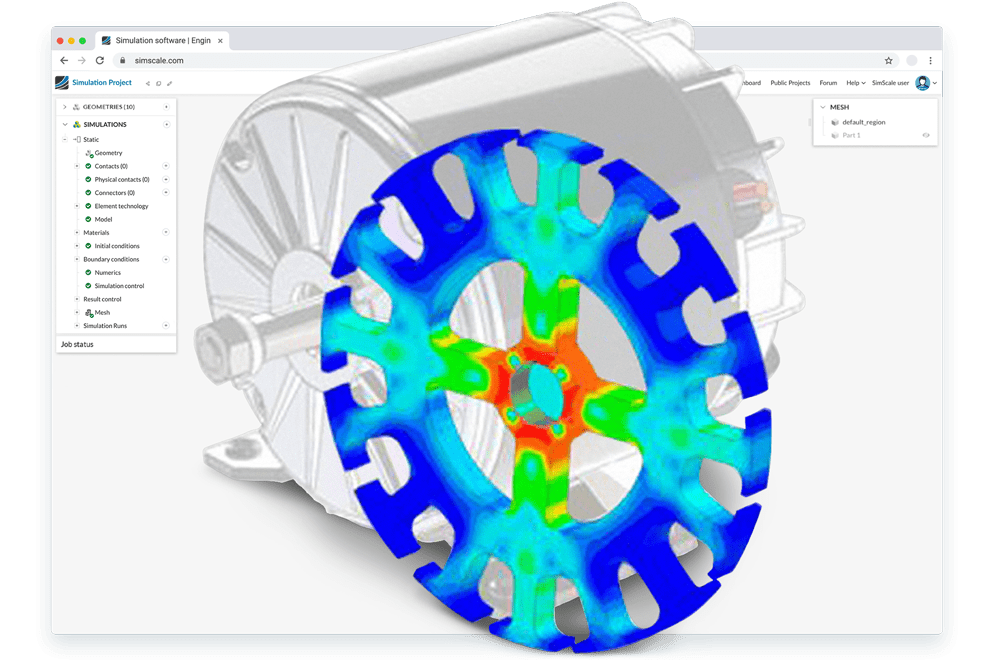

Incorporate advanced physics solvers for all turbomachinery applications using CFD, heat transfer, and structural dynamics analyses. SimScale allows you to generate fast performance curves and analyze the fluid flow and thermomechanical behavior of the turbomachine under varying operating conditions.

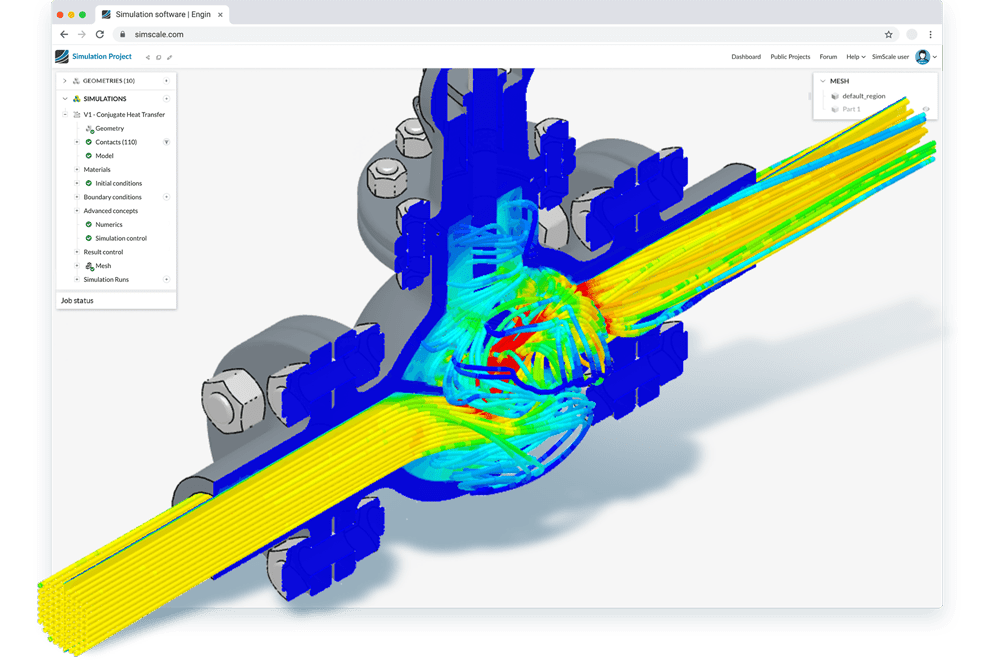

The SimScale workbench offers CFD, structural, and thermal analyses of valves, piping, and HVAC systems along with embedded pre and post-processing all through your web browser.

Bring in any kind of valve geometry and run a multiphysics simulation to obtain pressure drops and flow coefficient across operating points within minutes, and evaluate the structural response to fluid pressure as well as the thermomechanical stress on it.

For industrial equipment with rotating components, designers and engineers can run fast and accurate simulations of entire assemblies to reliably predict system-level performance and reduce time-to-market as well as cost of production. SimScale is perfectly suited for simulating all types of machinery and industrial equipment across many different industries, including construction, mining, automotive, chemical, and steel industries.

With SimScale, investing in expensive high-performance computing hardware and caring for software installation and maintenance are a thing of the past.

Save on thousands of dollars by cutting the cost of expensive hardware and software maintenance fees.

Connect to the Internet and run demanding simulations on any laptop or PC. We take care of software updates for you in the background.

With our simple workflow and ready-to-use simulation templates and tutorials, you never have to start from scratch.

Sign up for SimScale

and start simulating now