I would like to do multilayer insulation for hot fluide flow through pipe, how to perform this?

what exactly is it you want to simulate/investigate in your multilayer insulation of a pipe? Are you interested in the thermal behavior/properties of the insulation itself or is it more about the resulting temperature distribution of the fluid (or both?). Also “how hot” are we talking? What is the temperature and velocity you are expecting? Depending on the material of the insulation, the former one could be done with a heat transfer analysis through a solid body (search for “thermal” in the simulation library to see some examples). If you are more interested in the flow part of the system, there are different flow simulation types you can use - depending on how hot and fast your fluid will be.

Could you elaborate a bit more on the application itself, then I could maybe give a more concrete hint!

Best,

David

Dear Sir,

Details of problem are as follows

10’ MS pipe of 1 meter length having super heated steam flow with 800 tons/hr at 540 degree Cecilius.

inner layer of ceramic material, thickness 50mm, density 128kg/m3, thermal conductivity 0.12 W/mk

outer layer of nitrile rubber, thickness 19mm, density 40kg/m3, thermal conductivity 0.037 W/mk,

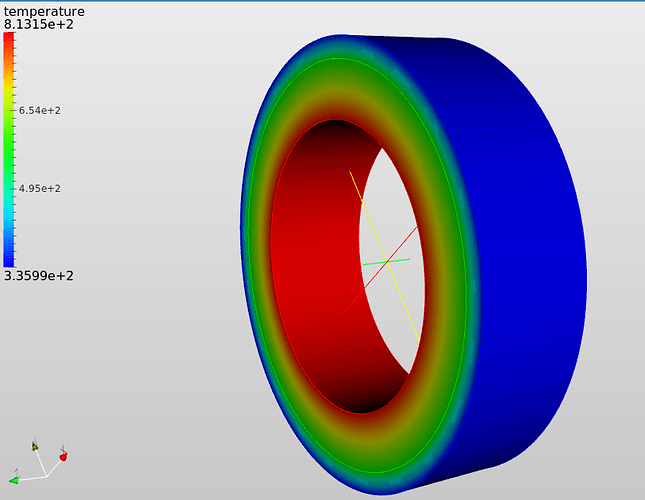

temperature remains same. I would like to find the intermediate temperature through the cross section and temperature throughout the pipe.

Thank you for the co operation,

Regards,

Vinayak

Vinayak @nayakvr,

that’s quite a speed and temperature - very interesting! The simulation of the entire system coupled including heat transfer between solid and fluid phase is not yet possible on SimScale. Depending on the exact properties of the steam (does it stay super heated everywhere or could a phase change appear) you could simulate the fluid region (@gholami, @jprobst, correct me if I am wrong on this one ) and the solid region separately. So you could assume a homogeneous heat transfer coefficient for the fluid->ceramic material and simulate the flow. Would such an approximation make sense for your work?

Best,

David

Hi @nayakvr,

the full-blown simulation requires a coupling between the fluid and solid reason which is unfortunately not yet available (but we’re working on it  )

)

To me this looks like this problem is best solved with solid mechanics. You can assume a convective heat transfer boundary condition at the inside of the pipe. Therefore you have to estimate a heat transfer coefficient for the this interface. Additionally you just need a sensible boundary condition for the outside of your pipe and you’re set.

This should give you a sensible radial temperature distribution across your pipe. In axial direction however, it will not change (think of it as a 3D problem which degenerates into 2D under these assumptions). If you want to achieve this, you have to do a fluid simulation as well, as outlined by @dheiny.

Hannes

Hi @iprobst

you are right sir, now told me that how to connect the mesh between the steam and pipe, pipe and insulation material? to give their properties and start to solve analysis…

Hi @nayakvr no problem! I need some assistance though  @rszoeke could you please help us here and give a short answer how the thermal contact should be defined?

@rszoeke could you please help us here and give a short answer how the thermal contact should be defined?

Hi @nayakvr,

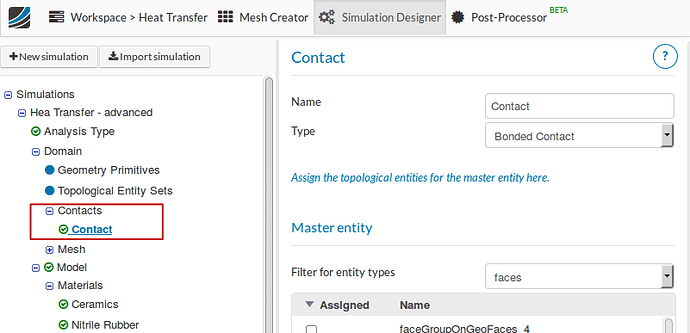

creating a thermal contact is actually fairly easy, you just have to add a “bonded contact” between the inner surface of the outer layer and the outer surface of the inner layer:

Here is the link to an example project I just created that could be used as a starting point for your analysis:

https://platform.simscale.com/?publiclink=df480fb8-a02e-4344-a148-a5b5df4954ca

Have fun!

Best,

Richard