Dear Team,

I am solving a problem in hyper-elastic area with Mooney-Rivlin constants. When i am applying the torque of 1 kNm its working fine, but applying 10 kNm its going to be diverge. How to over come this problem.

Hello @duraisamy,

can you share a link to your project? With this little information it is impossible to tell what the problem might be.

Best,

Richard

Hi @rszoeke

DEBUT();

ST=LIRE_MAILLAGE(UNITE=20, FORMAT=‘MED’,);

RT=LIRE_MAILLAGE(UNITE=21, FORMAT=‘MED’,);

MS1=LIRE_MAILLAGE(UNITE=22, FORMAT=‘MED’,);

MS2=LIRE_MAILLAGE(UNITE=23, FORMAT=‘MED’,);

RB=LIRE_MAILLAGE(UNITE=24, FORMAT=‘MED’,);

SB=LIRE_MAILLAGE(UNITE=25, FORMAT=‘MED’,);

mesh1=ASSE_MAILLAGE(MAILLAGE_1=ST, MAILLAGE_2=RT, OPERATION=‘SUPERPOSE’,);

mesh2=ASSE_MAILLAGE(MAILLAGE_1=mesh1, MAILLAGE_2=MS1, OPERATION=‘SUPERPOSE’,);

mesh3=ASSE_MAILLAGE(MAILLAGE_1=mesh2, MAILLAGE_2=MS2, OPERATION=‘SUPERPOSE’,);

mesh4=ASSE_MAILLAGE(MAILLAGE_1=mesh3, MAILLAGE_2=RB, OPERATION=‘SUPERPOSE’,);

mesh5=ASSE_MAILLAGE(MAILLAGE_1=mesh4, MAILLAGE_2=SB, OPERATION=‘SUPERPOSE’,);

mesh=CREA_MAILLAGE(MAILLAGE=mesh5,

CREA_POI1=(_F(NOM_GROUP_MA=‘load’,GROUP_NO=‘load’,),),);

mesh=DEFI_GROUP(MAILLAGE=mesh,CREA_GROUP_NO=_F(TOUT_GROUP_MA=‘OUI’,),reuse=mesh,);

model=AFFE_MODELE(MAILLAGE=mesh, AFFE=(_F(TOUT=‘OUI’, PHENOMENE=‘MECANIQUE’, MODELISATION=‘3D’,),

_F(GROUP_MA=‘load’,PHENOMENE=‘MECANIQUE’,MODELISATION=‘DIS_TR’,),),);

CS=DEFI_MATERIAU(ELAS=_F(E=2e11, NU=0.3, RHO=7860,),);

C10 = 3.8E6;

C01 = -2.95E6;

C20 = 0.0;

NU = 0.499;

K = ((6 * (C10 + C01)) / (3 * (1 - (2 * NU))));

rubber=DEFI_MATERIAU(ELAS_HYPER=_F(C10=C10,

C01=C01,

C20=C20,

K=K,

RHO=1091.0,),);

U4.43.03

material=AFFE_MATERIAU(MAILLAGE=mesh, AFFE=(_F(GROUP_MA=(‘steel_top_V’,‘middle_steel_1’,‘middle_steel_2’,‘steel_bot_V’,), MATER=CS,),

_F(GROUP_MA=(‘Rubber_top_V’,‘Rubber_bot_V’,), MATER=rubber,),),);

fixed=AFFE_CHAR_MECA(MODELE=model, DDL_IMPO=_F(GROUP_MA=(‘Fix_1’,),DX=0,DY=0,DZ=0,),);

CARA=AFFE_CARA_ELEM(MODELE=model,

DISCRET=_F(CARA=‘K_TR_D_N’,

GROUP_MA=‘load’,

VALE=(0.1,0.1,0.1,0.1,0.1,0.1,),),);

U4.44.01

@Eff@#LoadList#pressure;Pressure;fix2;1e6;NA;NA;NA;NA;NA

f1=AFFE_CHAR_MECA(MODELE=model, FORCE_NODALE=_F(GROUP_NO=‘load’, MY=31E3,),LIAISON_SOLIDE=_F(GROUP_NO=‘twister’,),),;

glue contacts

c1=AFFE_CHAR_MECA(MODELE=model, LIAISON_MAIL=(

_F(GROUP_MA_MAIT=‘steel_top_V’, GROUP_MA_ESCL=‘RT_st’, TYPE_RACCORD=‘MASSIF’,),),);

c2=AFFE_CHAR_MECA(MODELE=model, LIAISON_MAIL=(

_F(GROUP_MA_MAIT=‘middle_steel_1’, GROUP_MA_ESCL=‘RT_ms’, TYPE_RACCORD=‘MASSIF’,),),);

c3=AFFE_CHAR_MECA(MODELE=model, LIAISON_MAIL=(

_F(GROUP_MA_MAIT=‘middle_steel_1’, GROUP_MA_ESCL=‘mid_2’, TYPE_RACCORD=‘MASSIF’,),),);

c4=AFFE_CHAR_MECA(MODELE=model, LIAISON_MAIL=(

_F(GROUP_MA_MAIT=‘middle_steel_2’, GROUP_MA_ESCL=‘RB_ms’, TYPE_RACCORD=‘MASSIF’,),),);

c5=AFFE_CHAR_MECA(MODELE=model, LIAISON_MAIL=(

_F(GROUP_MA_MAIT=‘steel_bot_V’, GROUP_MA_ESCL=‘RB_st’, TYPE_RACCORD=‘MASSIF’,),),);

time steps

load1=DEFI_FONCTION(NOM_PARA=‘INST’,VALE=(0,0,1,1,),);

step1=DEFI_LIST_REEL(DEBUT=0, INTERVALLE=_F(JUSQU_A=1.0, PAS=0.1,),);

step=DEFI_LIST_INST(DEFI_LIST=_F(METHODE=‘AUTO’, LIST_INST=step1,),);

RESU=STAT_NON_LINE(MODELE=model,

CARA_ELEM=CARA,

CHAM_MATER=material,

EXCIT=(_F(CHARGE=fixed,),

_F(CHARGE=f1,FONC_MULT=load1,),

_F(CHARGE=c1,),

_F(CHARGE=c2,),

_F(CHARGE=c3,),

_F(CHARGE=c4,),

_F(CHARGE=c5,),),

INCREMENT=_F(LIST_INST=step,),NEWTON=_F( REAC_INCR=1, MATRICE= ‘TANGENTE’, REAC_ITER=1,),

CONVERGENCE=_F(ITER_GLOB_MAXI=500,RESI_GLOB_RELA=1e-05,),

COMPORTEMENT=(_F(GROUP_MA=(‘Rubber_top_V’,‘Rubber_bot_V’),RELATION=‘ELAS_HYPER’,DEFORMATION=‘GROT_GDEP’,),

_F(GROUP_MA=(‘steel_top_V’,‘middle_steel_1’,‘middle_steel_2’,‘steel_bot_V’,),RELATION=‘ELAS’,DEFORMATION=‘GROT_GDEP’,),),

);

RESU=CALC_CHAMP(reuse=RESU,

RESULTAT=RESU,

CONTRAINTE=(‘SIGM_ELNO’,‘SIGM_NOEU’),

CRITERES=(‘SIEQ_ELNO’,‘SIEQ_NOEU’,),

DEFORMATION=(‘EPSI_ELNO’,‘EPSI_NOEU’,‘EPSG_NOEU’,),

FORCE=(‘REAC_NODA’,),);

IMPR_RESU(FORMAT=‘MED’,

RESU=(_F(RESULTAT=RESU,

NOM_CHAM_MED=(‘Displacement (m)’, ),

INFO_MAILLAGE=‘NON’,

NOM_CMP=(‘DX’, ‘DY’,‘DZ’,),

IMPR_NOM_VARI=‘NON’,

NOM_CHAM=(‘DEPL’, ),),

_F(RESULTAT=RESU,

NOM_CHAM_MED=('Normal cauchy stress (Pa)', ),

INFO_MAILLAGE='NON',

NOM_CMP=('SIXX', 'SIYY','SIZZ', 'SIXY', 'SIXZ', 'SIYZ'),

IMPR_NOM_VARI='NON',

NOM_CHAM=('SIGM_NOEU', ),),

_F(RESULTAT=RESU,

NOM_CHAM_MED=('Nonlinear strain', ),

INFO_MAILLAGE='NON',

NOM_CMP=('EPXX', 'EPYY', 'EPZZ', 'EPXY', 'EPXZ', 'EPYZ'),

IMPR_NOM_VARI='NON',

NOM_CHAM=('EPSG_NOEU', ),),

_F(RESULTAT=RESU,

NOM_CHAM_MED=('von Mises stress (Pa)', ),

INFO_MAILLAGE='NON',

#NOM_CMP=('VMIS', ),

IMPR_NOM_VARI='NON',

NOM_CHAM=('SIEQ_NOEU', ),),

_F(RESULTAT=RESU,

NOM_CHAM_MED=('Reaction Force (N)', ),

INFO_MAILLAGE='NON',

#NOM_CMP=('VMIS', ),

IMPR_NOM_VARI='NON',

NOM_CHAM=('REAC_NODA', ),),

),

UNITE=80,

INFO=1,)

reac=POST_RELEVE_T(

ACTION=_F(

INTITULE=‘REACTION_FORCE’,

GROUP_NO=(‘Re’,),

RESULTAT=RESU,

NOM_CHAM=‘REAC_NODA’,

RESULTANTE=(‘DX’,‘DY’,‘DZ’,),

MOMENT=(‘DRX’,‘DRY’,‘DRZ’,),

POINT=(0,0,0,),

OPERATION=‘EXTRACTION’,

),

);

IMPR_TABLE (TABLE=reac,UNITE=8,)

FIN();

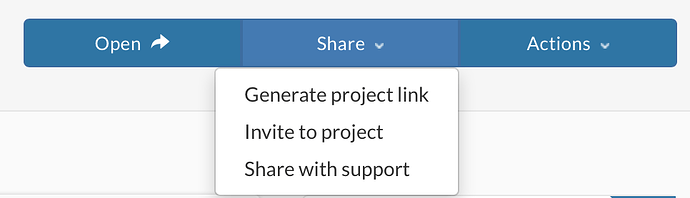

Hi @duraisamy,

you should share your project like this.

Click on Generate project link and share the link that you get with us. As I saw you already deleted the related simulation. Can you generate it again and share it with us please?

Thanks and cheers!

Jousef

@jousefm this project was not created with SimScale, it was directly done using Code_Aster locally.

@duraisamy, can you also share the meshes such that we can reproduce the run? I saw that you also posted directly into the Code_Aster forum, I guess that’s also the more appropriate place, since SimScale users will have a hard time debugging your simulation that was done with a local simulation setup that is not reproducible on SimScale.

Nevertheless, if you can provide the meshes, I will try my best to help finding the problem.

Best,

Richard

@rszoeke

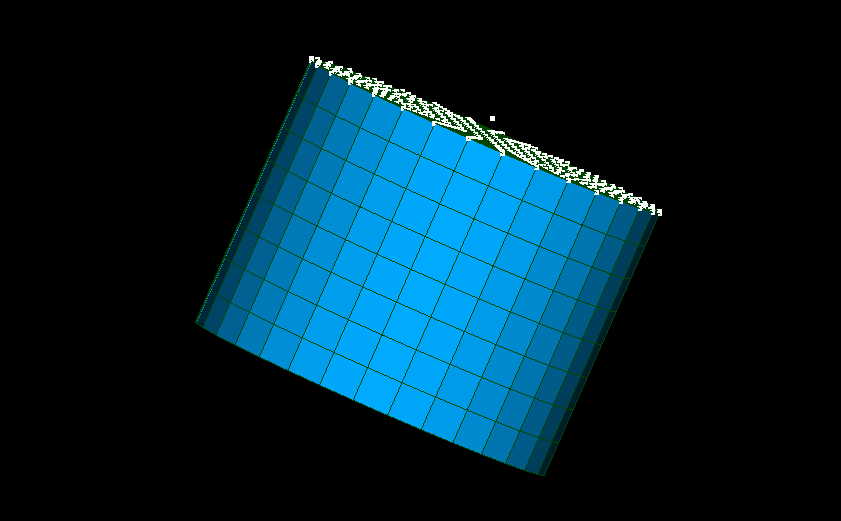

How to apply the torque ref the figure

https://www.simscale.com/workbench?publiclink=4437e86a-a28d-4676-8048-bc6fbe03f48b

Hi @duraisamy,

I think you have a scaling problem with your geometries, that’s why the 2nd simulation does not work.

You have cylinders in the range of 200[m] and only apply 41[N] compressive load. You can use the scaling operation on the geometry to scale it down to the actual size.

Best,

Richard

Regarding your initial query,

I think the problem might be that the higher load generates a too high rotation angle and that the approach you are using (LIAISON_SOLIDE - or with SimScale it would be “undeformable remote force”) only allows small rotations.

In recent Code_Aster versions you can turn on support for large rotation by defining the LIAISON_SOLIDE as a follower load, this should improve the situation and at least allow a higher load until divergence.

Best,

Richard

Thank you

My cylinder object dimension is X=100 mm, Y=100 mm and Z = 600 mm.

Mooney rivlin constants are in Mpa

Ok, then everything should be fine,

but the load is then still in Newton for a consistent unit system.

So in case you wanted to apply 41 kN you have to define your load as 41 000 [N].

Best,

Richard

I am using 41e3 Nm only

Hello @duraisamy,

I think a few things got mixed up, so I’ll sum it up again with references:

-

In your command file that you posted here you are using SI units in the comm file, I can’t judge about the mesh units.

-

In the project you shared in your next post, you are still unsing SI units for the simulation setup, but your geometry is obviously scaled to Millimeters.

-

In your 2nd shared project from the consecutive post I see now SI units for the material properties (besides the densitiy which is irrelevant here), but in your force load, you are using the formula “t*4” [N].

I would suggest you setting up the same case from the comm file with SimScale. You can use this example as a reference how to set up a torque. For the sake of simplicity I would propose to upload the geometry directly in SI units, this could prevent some confusion.

Best,

Richard