Silent-Aire is a technology-driven company that designs, engineers, and manufactures hyperscale cooling and modular data center solutions. Their portfolio of solutions includes modular data centers; power room modules, turnkey modular deployments, custom HVAC (CRACs, CRAHUs, AHUs) and mission critical services. Silent-Aire employs over 3000 people, with a total of 13 manufacturing facilities worldwide. Silent-Aire is considered a leading expert in the design, testing, and manufacturing of innovative and low energy ventilation and cooling systems and solutions. Their focus on air movement means they need the best physics-based airflow simulation software available, accesible from anywhere and at any time. Silent-Aire has been using SimScale to design and optimize its ventilation and HVAC units, saving considerable time and cost by replacing expensive physical prototyping with digital twins in the SimScale platform.

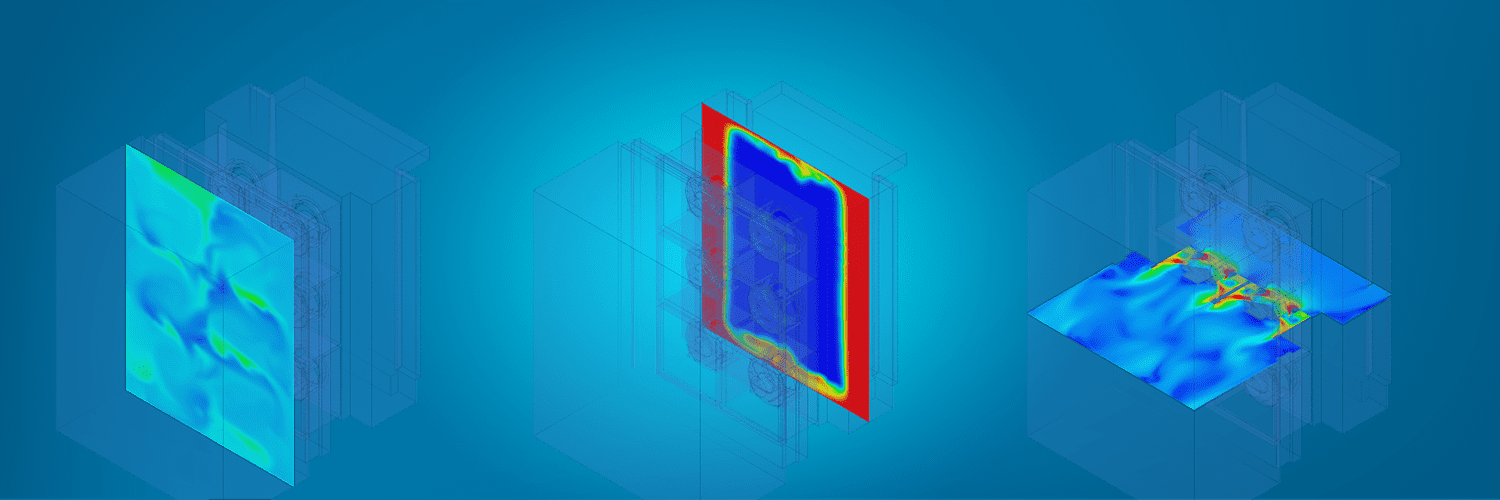

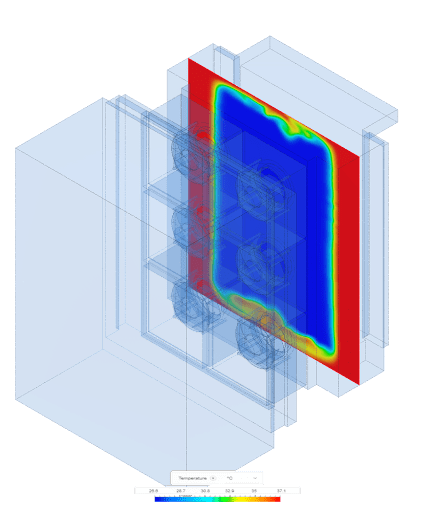

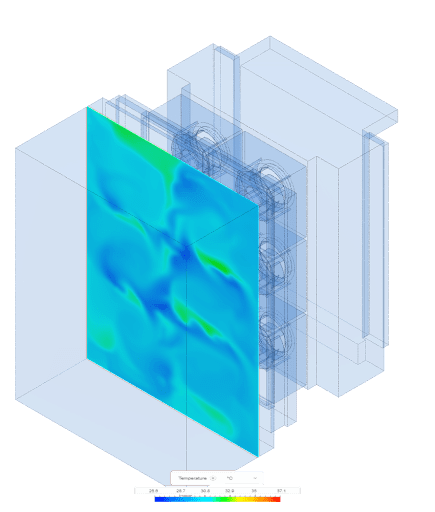

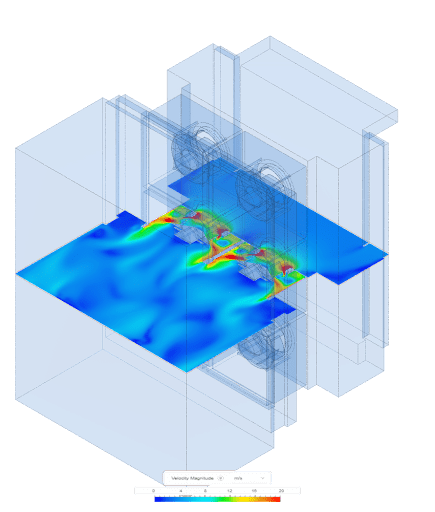

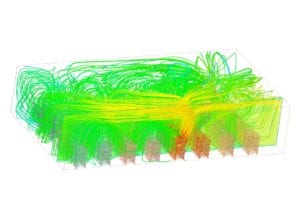

This case study is based on a live research project to develop and test a novel HVAC unit’s mixing performance under various airflow and temperature conditions applied to the model. The main purpose of the simulation analysis was to validate the mixing performance of the air handling unit (AHU) when part of the airflow was bypassing an evaporative cooling system within the AHU itself. The critical design condition was that no parts of the downstream airflow should vary more than ±0.8°C versus the average supply air temperature. This was to replicate actual operating conditions in the client’s critical facility.

This analysis was designed in such a way to match the real factory witness testing (FWT) that would be carried out on the first-of-kind prototype unit as closely as possible. This FWT test unit had 24 temperature sensors installed within it, in the same locations as the 24 probe points added in the SimScale simulation, giving a true digital twin capability. Due to the high number of units required by the client (320 AHUs for the first two projects) their performance needed to be validated and verified before the design could be signed off on by the client’s engineering consultants and before the first prototype could be built.

The ability to pre-test the AHU performance in SimScale was considered a crucial step in de-risking the development of novel features in a high-performing HVAC unit in a critical facility. Silent-Aire modeled several different internal layouts to see what design would yield the optimum mixing performance.

Lead Mechanical Design Engineer, Shane McConn, has been driving the adoption of SimScale in the engineering design team. Shane had some prior CFD experience, yet remarks on how intuitive and easy to use the SimScale interface is. Shane started with the free trial version originally, a great way for engineers to get started with SimScale. He started using the template projects in the public library and was quickly able to set up, run, and visualize simulation results. Shane has been particularly complimentary of the visual outputs from SimScale, describing them as important for communicating the results to their clients.

Months of engineering work can now be done in an evening.

Shane McConn

Lead Mechanical Design Engineer at Silent-Aire

The main benefits to Shane and his team include:

A typical development process before Silent-Aire embedded simulation in their workflow would have included building an initial test unit with a 4-6 week pre-testing phase and 85 engineering man-hours needed to test/optimize the design.

Using SimScale this same process now takes 2-3 weeks of pre-testing and only 40 engineering man-hours. Using simulation, Silent-Aire has cut their product development and testing time and cost down by half (50%) on recent projects.

Silent-Aire is expanding access to SimScale across the engineering team. Graduate engineers are being trained by SimScale and this will enhance the rapid digital prototyping capabilities at Silent-Aire moving forward. With multiple users, Silent-Aire will also benefit from the built-in collaboration and enterprise features that streamline simulation user management and administration, as well as support to automate simulations using the SimScale API.

Sign up for SimScale

and start simulating now