The heating, ventilation, and air conditioning (HVAC) industry is facing major changes as a result of technological progress and the emergence of the Internet of things (IoT). With new products being launched every day, HVAC engineers and manufacturers must find new and innovative ways to meet growing customer needs and expectations. In addition to this, they must stay on top of the ever-changing industry standards regarding energy efficiency, comfort, and performance.

Moreover, due to “sick building syndrome”, an HVAC engineer must pay close attention to indoor air quality (IAQ)—a topic expected to be tackled by HVAC manufacturers.

Here are some tips for every HVAC engineer to consider based on the industry’s evolution and trends:

HVAC Engineering 1. Focus on Energy-Efficient HVAC Equipment

Carbon emissions and energy consumption are key topics when it comes to creating more efficient buildings. Within the construction sector, HVAC equipment plays an important part in reducing wasteful energy usage.

Zero-energy buildings are becoming more and more popular among both homeowners and companies with office buildings. This growing trend has increased the demand for geothermal heating and cooling, solar-powered systems, and white roofing. All of these trends are significantly impacting air conditioning, heating, and ventilation manufacturers, as new regulations regarding energy efficiency are expected to be implemented in the upcoming years.

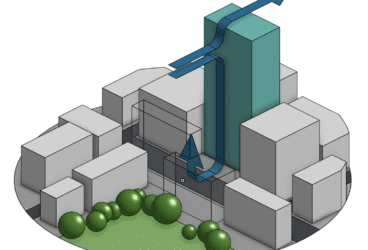

With these advancements in technology and the efforts of every HVAC engineer to increase efficiency, smart buildings, smart grid technologies, and smart cities are becoming a reality and creating a new era in the construction and HVAC industries.

HVAC Engineering 2. Create Environmentally Friendly Systems

Companies are expanding their efforts to create energy-efficient systems throughout the entire production process. This is in large part due to the increasing regulations regarding the use of environmentally-friendly materials, products, and substances in the manufacturing of the heating, ventilation, air conditioning, and even refrigeration (HVACR) equipment. This helps HVAC engineers to create products with the lowest possible impact on the environment.

These efforts include companies who are specialized in refrigeration, as customers in this sector demand the use of natural refrigerants, such as ammonia, carbon dioxide, and even propane, replacing the traditional fluorocarbons, which have a negative impact on global warming.[1]

HVAC Engineering 3. Software is Not a Thing to Ignore, Nor is Smart Technology

As one of the leading industries in the technology field, HVAC is pushing for continued innovation in smart devices. Smart thermostat technology, smart equipment integration, and IoT are all part of this global movement.

Leading the smart controllers market, the Nest Thermostat is revolutionizing the HVAC industry. This intelligent device creates a custom schedule for homes and even remembers preferred temperatures based on the time of the day or season. Following the industry focus on energy saving, the 3rd generation Nest Learning Thermostat™ is proven to save 10 to 12% on heating bills and 15% on the cooling bills [2], by automatically adjusting the temperature settings to optimize energy savings. With the possibility of being controlled remotely from a smartphone, tablet, or laptop, it significantly reduces energy waste. Moreover, this type of device can provide helpful prompts and notifications about possible problems of a heating system.

With many other features relating to both comfort and safety in buildings (it can automatically shut off fossil fuel-based heating systems, in the case of CO leaks in the home), the Nest Thermostat and other similar devices are being embraced by HVAC engineers, designers and architects and integrated into their systems.

Direct digital control (DDC) systems are another example of how software is fundamentally changing the products that are being brought to market. Using digital processors, DDC systems enable users to remotely monitor, control, alarm and diagnose HVAC equipment.

By embracing these new technologies, an HVAC engineer can focus on all-in-one software solutions that help ensure indoor comfort in a convenient and seamless manner.

Moreover, as a result of the continued integration of mobile phones into everyday life, HVAC maintenance and service is expected to rely on mobile applications to become more efficient.

HVAC Engineering 4. Consider Engineering Simulation, Every Smart HVAC Engineer Does

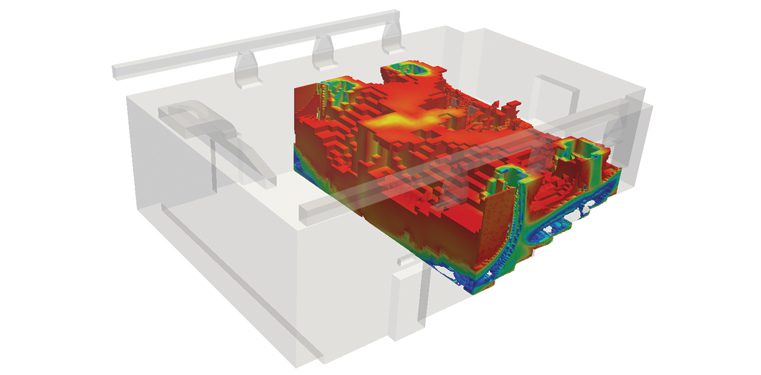

Results of a CFD simulation that investigates thermal comfort in a theater, performed with SimScale

Computer-aided engineering (CAE or engineering simulation) brings tremendous advantages in meeting the design objectives of HVAC equipment manufacturers.

In the industry, simulation is being used to:

- Analyze and optimize the design of air conditioning, heating, ventilation systems, fans, ducts, and more

- Ensure the performance of cooling and heating equipment

- Predict thermal comfort in residential or commercial buildings, offices, factories or even passengers cabins, by investigating air temperature, velocity, radiant temperature, etc.

- Predict fire or smoke propagation for safety control in tunnels, subway stations or parking garages and ensure air quality in healthcare facilities or laboratories

- Reduce energy supply for HVAC systems via better ducting, fan or cooling unit placement

- Comply with industry standards such as ASHRAE 55, EN 15251, ASHRAE 90.4

HVAC Engineering 5. Learn About Passive Survivability

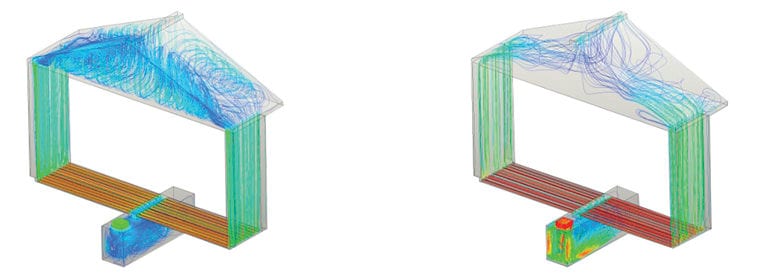

Streamline visualization of the ventilation system in active and passive cooling scenarios (left: active ventilation, right: passive ventilation) (Source: IBEEE Success Story)

Introduced after Hurricane Katrina in 2005, “passive survivability” refers to a building’s ability to maintain critical life-support conditions in the event of extended loss of power, heating fuel, or water. [3]

This potentially life-saving design is widely encouraged as a standard criterion for houses, apartment buildings, and schools. It is strongly linked to high-performance and renewable power design buildings, while “passive survivability” ensures that a home can continue to shelter inhabitants for a long period in the event of disasters such as storms, heatwaves, floods, or even droughts.

Conclusion

As more and more investments are being made in the construction industry, HVAC companies and HVAC engineers need to keep up with the changing trends at the forefront of this fast-growing sector. New technologies and energy efficiency are key topics in the coming years as manufacturers strive to remain competitive within the industry.

Download this case study for free to learn how the SimScale cloud-based CFD platform was used to investigate a ducting system and optimize its performance.

References

- https://www.achrnews.com/articles/123334-hvac-trends-to-watch?v=preview

- https://money.cnn.com/2015/09/01/technology/new-nest-thermostat/

- https://en.wikipedia.org/wiki/Passive_survivability