Well-designed cleanroom facilities are necessary for activities performed under a controlled environment with a low level of pollutants—a critical requirement for many manufacturing, pharmaceutical, and scientific research applications. One way to ensure a proper cleanroom design is through engineering simulation, especially computational fluid dynamics. Depending on the application, contaminating particles are often found in cleanrooms, and if not designed properly, could have negative effects on the product and those inside the lab. A cost-effective way to ensure contamination control is through SimScale’s CFD analysis solution. Cleanrooms can use up to 50 times more energy than non-classified areas, and this can get expensive. With high regulatory standards, optimizing energy efficiency is not only necessary but can have added financial benefits. Using simulation software as part of the design process, engineers can evaluate their design performance, optimize airflow and air change effectiveness, decrease the risk of contamination, and increase energy efficiency.

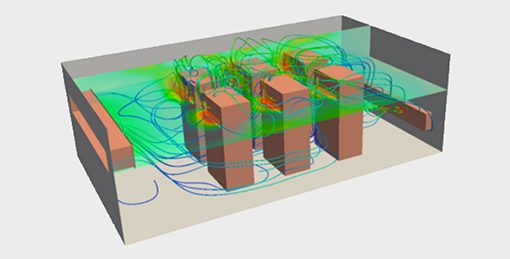

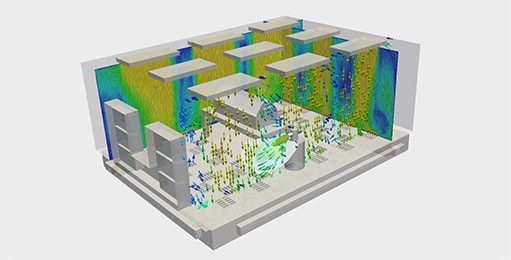

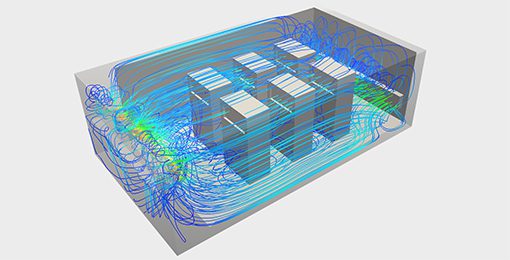

Assess air circulation flow patterns. With this simulation focus, you can identify zones of the cleanroom that might be troublesome to ventilate.

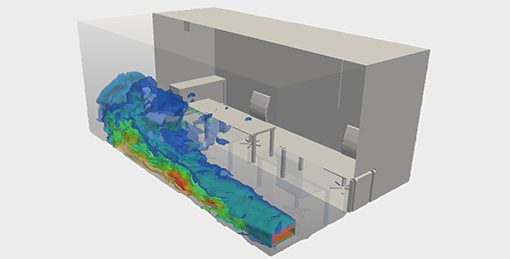

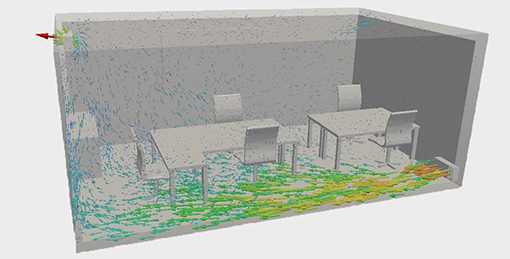

The CFD analysis enables you to predict the behavior of the contaminant within the room. Tracking will allow a greater control over potential work hazards.

Evaluate the air speed within the room. Identify areas of high flow velocity. Modify the room design to ensure steady air movement throughout the whole domain.

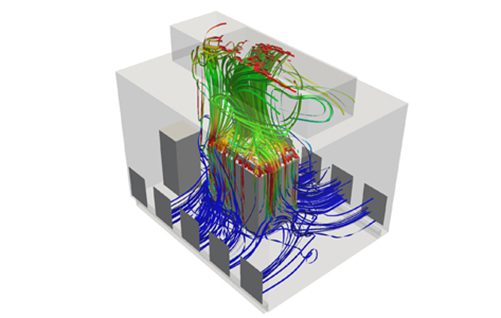

Analyze temperature distribution within the room or the cooling or heating performance of room components. Ensure steady operational conditions for lab equipment.

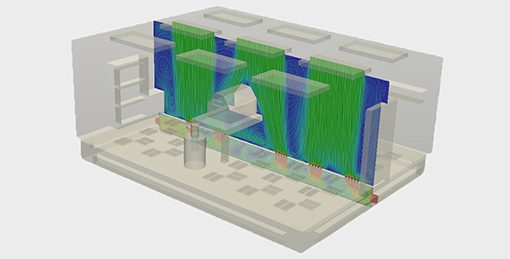

Investigate the air flow within the room at different operation conditions. Check the performance of laminar chambers, suction systems, safety ventilation.

Calculate the time required to remove all contaminants and to exchange the air within the cleanroom.

SimScale Community gives you access to completed public cleanroom design simulation projects for free. Use their setup as a template and perform Fluid Dynamics, Thermal and Solid Mechanics analyses.

Thermo-Consult is an engineering office specialized in HVAC & R systems that created a multi-operational state ventilation system in a cleanroom for an electron microscope. The customer’s engineers used SimScale to investigate the airflow for ensuring that the temperature does not exceed certain values and that the air speed in different places is not above the limits.

I have used a lot of simulation packages over the past 25 years, including Nastran, Ansys, SolidWorks, and a whole host of others. I have been using SimScale for about nine months now and it has become my goto simulation tool. It allows me to run models larger than I have ever conceived on my own workstation.

Christopher Quijano Mechanical Engineer at MSA, United States

Sign up for SimScale

and start simulating now